| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1163742 | Analytica Chimica Acta | 2015 | 6 Pages |

•.The color changes of Cu-BTC with trace water was investigated.•.A fiber optic gas sensor with metal organic frameworks as sensing material was well designed with solid state devices.•.Relatively rapid and sensitive sensor for trace water in industrial gases were developed.•.No significant effects on the sensitivity was observed by sample flow rate, and various kinds of sample gases.

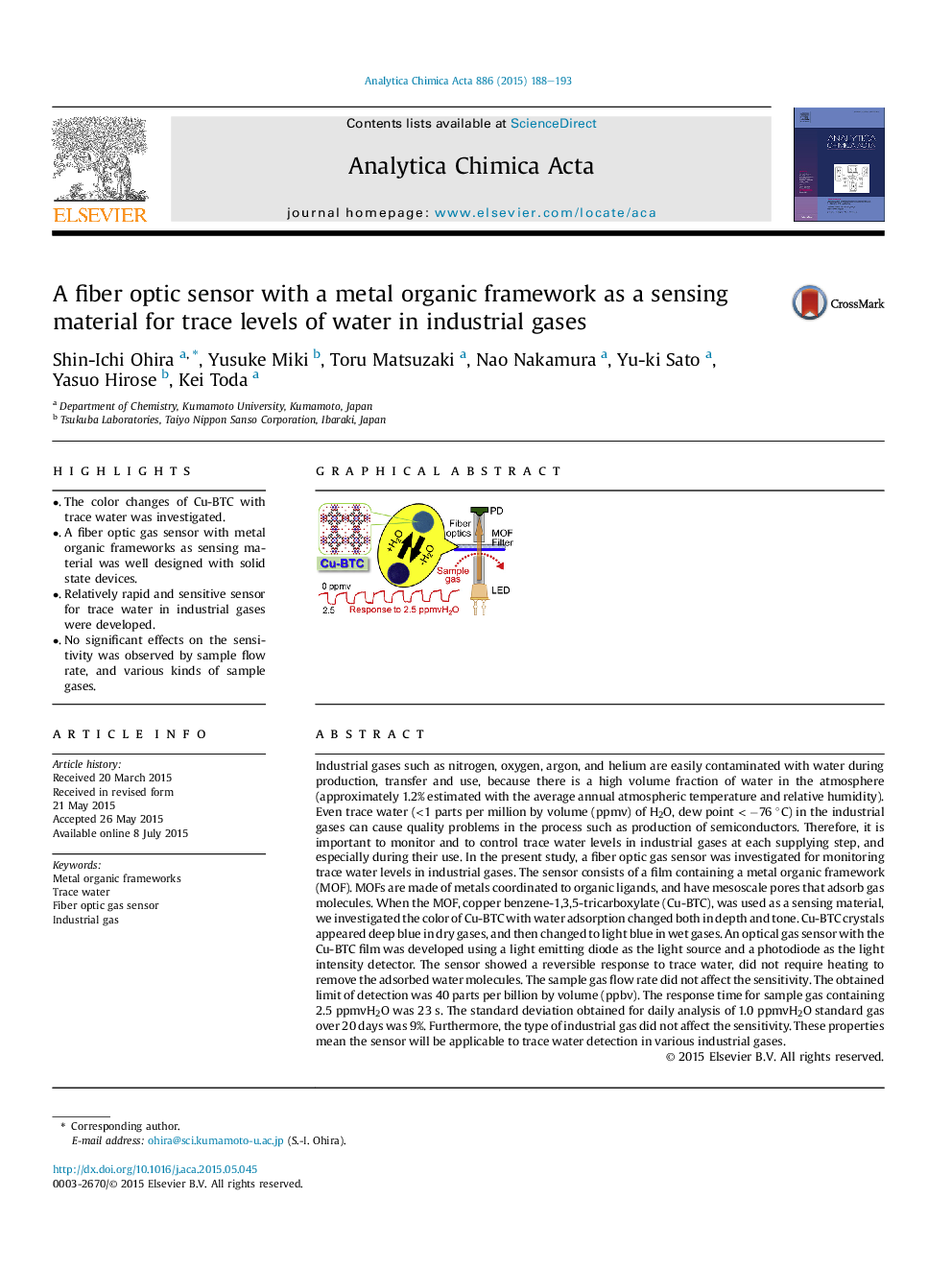

Industrial gases such as nitrogen, oxygen, argon, and helium are easily contaminated with water during production, transfer and use, because there is a high volume fraction of water in the atmosphere (approximately 1.2% estimated with the average annual atmospheric temperature and relative humidity). Even trace water (<1 parts per million by volume (ppmv) of H2O, dew point < −76 °C) in the industrial gases can cause quality problems in the process such as production of semiconductors. Therefore, it is important to monitor and to control trace water levels in industrial gases at each supplying step, and especially during their use. In the present study, a fiber optic gas sensor was investigated for monitoring trace water levels in industrial gases. The sensor consists of a film containing a metal organic framework (MOF). MOFs are made of metals coordinated to organic ligands, and have mesoscale pores that adsorb gas molecules. When the MOF, copper benzene-1,3,5-tricarboxylate (Cu-BTC), was used as a sensing material, we investigated the color of Cu-BTC with water adsorption changed both in depth and tone. Cu-BTC crystals appeared deep blue in dry gases, and then changed to light blue in wet gases. An optical gas sensor with the Cu-BTC film was developed using a light emitting diode as the light source and a photodiode as the light intensity detector. The sensor showed a reversible response to trace water, did not require heating to remove the adsorbed water molecules. The sample gas flow rate did not affect the sensitivity. The obtained limit of detection was 40 parts per billion by volume (ppbv). The response time for sample gas containing 2.5 ppmvH2O was 23 s. The standard deviation obtained for daily analysis of 1.0 ppmvH2O standard gas over 20 days was 9%. Furthermore, the type of industrial gas did not affect the sensitivity. These properties mean the sensor will be applicable to trace water detection in various industrial gases.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide