| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1564864 | Journal of Nuclear Materials | 2015 | 8 Pages |

•The oxides formed over 403 and 410 SS are spinels similar to magnetite.•Oxide is duplex in nature with chromium rich inner layer.•Dilute Chemical Decontamination process could dissolve only 60% of the oxide.•Oxidation-Reduction process dissolves 100% oxide layer but time consuming.•High Temperature process is 100% efficient and less time consuming.

Full system decontamination of Primary Heat Transport (PHT) system of Pressurised Heavy Water Reactors (PHWRs) resulted in low decontamination factors (DF) on stainless steel (SS) surfaces. Hence, studies were carried out with 403 SS and 410 SS that are the material of construction of “End-Fitting body” and “End-Fitting Liner tubes”. Three formulations were evaluated for the dissolution of passive films formed over these alloys viz., i) Two-step process consisting of oxidation and reduction reactions, ii) Dilute Chemical Decontamination (DCD) and iii) High Temperature Process. The two-step and high temperature processes could dissolve the oxide completely while the DCD process could remove only 60%. Various techniques like XRD, Raman spectroscopy and SEM-EDX were used for assessing the dissolution process. The two-step process is time consuming, laborious while the high temperature process is less time consuming and is recommended for SS decontamination.

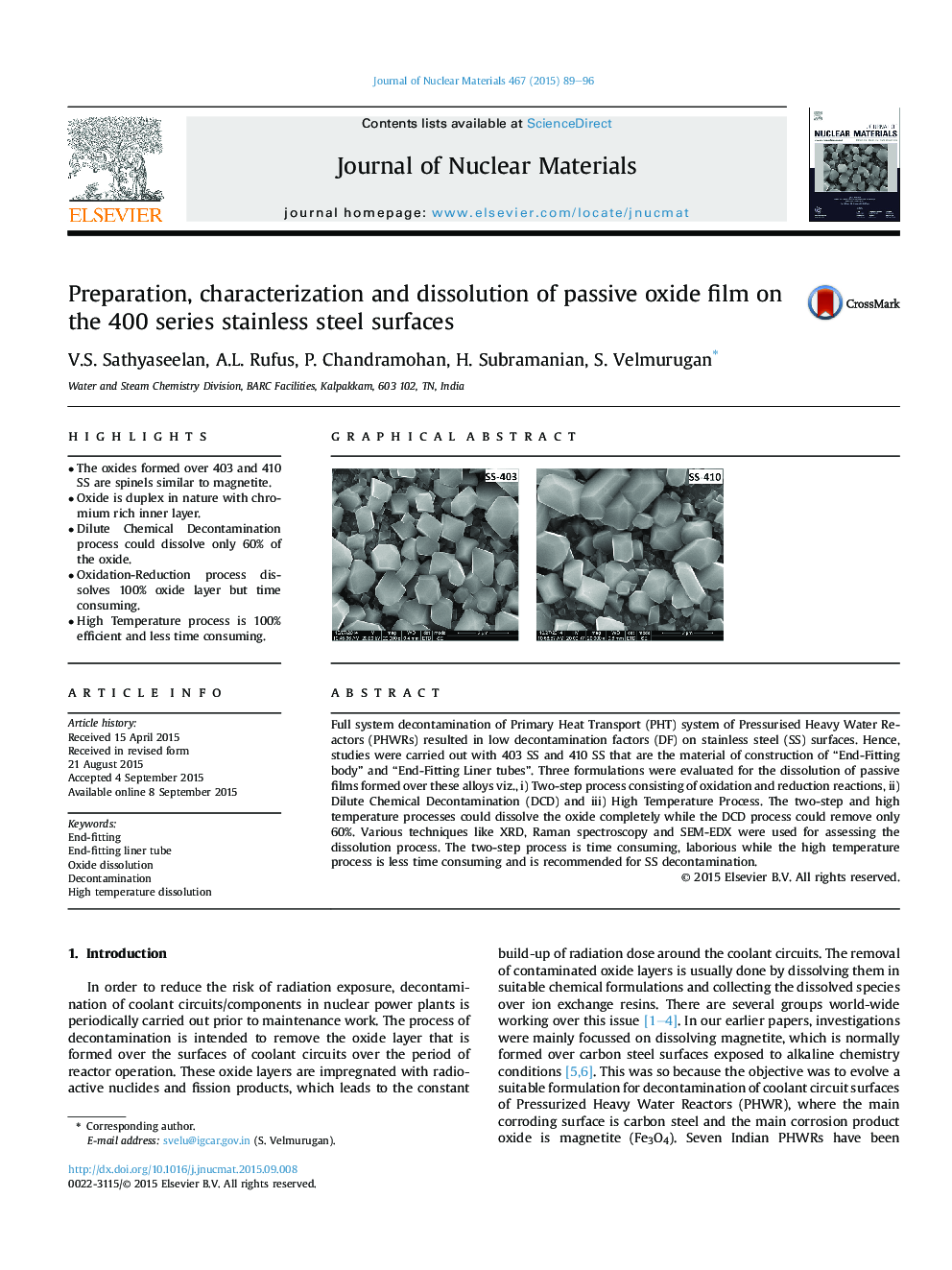

Graphical abstractSEM micrograph of the oxide film formed in an autoclave over the 403 SS and 410 SS surfaces, the “End-Fitting Body and End-Fitting Liner” materials of Pressurized Heavy Water Reactor (PHWR).Figure optionsDownload full-size imageDownload as PowerPoint slide