| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1679353 | CIRP Annals - Manufacturing Technology | 2014 | 4 Pages |

Abstract

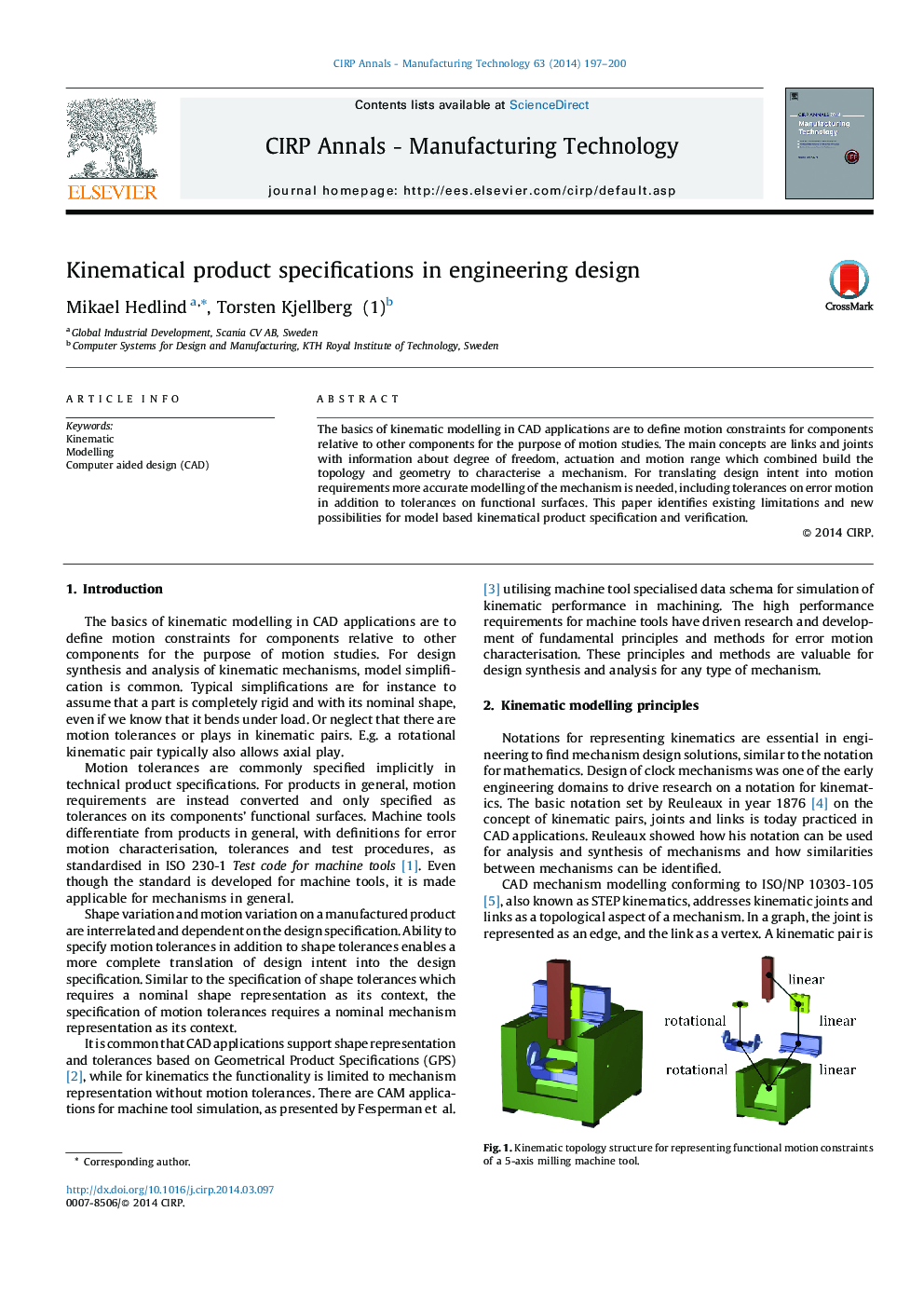

The basics of kinematic modelling in CAD applications are to define motion constraints for components relative to other components for the purpose of motion studies. The main concepts are links and joints with information about degree of freedom, actuation and motion range which combined build the topology and geometry to characterise a mechanism. For translating design intent into motion requirements more accurate modelling of the mechanism is needed, including tolerances on error motion in addition to tolerances on functional surfaces. This paper identifies existing limitations and new possibilities for model based kinematical product specification and verification.

Related Topics

Physical Sciences and Engineering

Engineering

Industrial and Manufacturing Engineering

Authors

Mikael Hedlind, Torsten Kjellberg,