| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 242902 | Applied Energy | 2013 | 11 Pages |

•A unique CO2 conversion technology using microorganisms was demonstrated.•Corn steep liquor medium enhanced production of n-butanol and n-hexanol.•Cotton seed extract (CSE) medium promoted ethanol formation.•CSE medium without morpholinoethanesulfonic acid buffer reduced the cost by 99%.

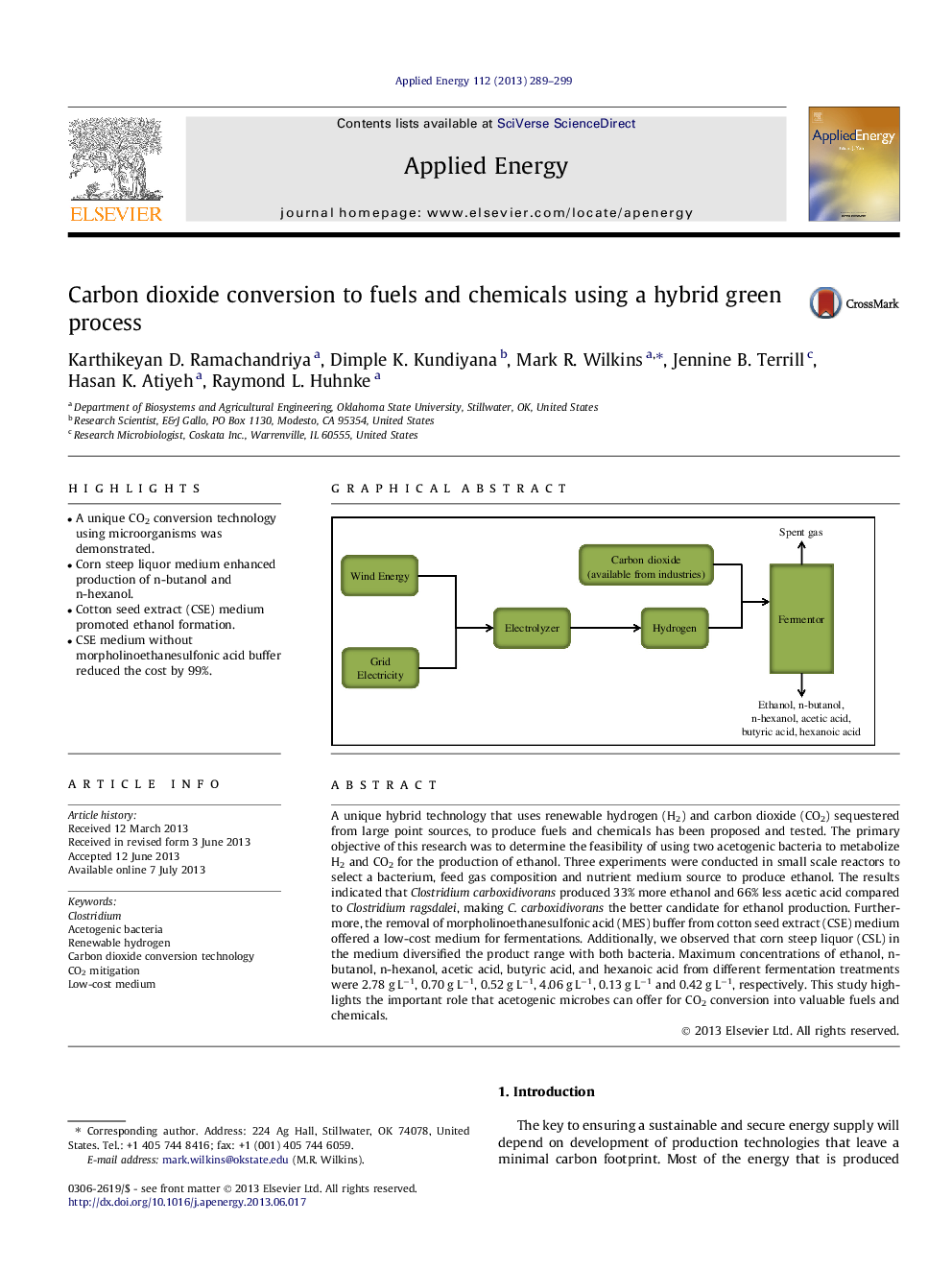

A unique hybrid technology that uses renewable hydrogen (H2) and carbon dioxide (CO2) sequestered from large point sources, to produce fuels and chemicals has been proposed and tested. The primary objective of this research was to determine the feasibility of using two acetogenic bacteria to metabolize H2 and CO2 for the production of ethanol. Three experiments were conducted in small scale reactors to select a bacterium, feed gas composition and nutrient medium source to produce ethanol. The results indicated that Clostridium carboxidivorans produced 33% more ethanol and 66% less acetic acid compared to Clostridium ragsdalei, making C. carboxidivorans the better candidate for ethanol production. Furthermore, the removal of morpholinoethanesulfonic acid (MES) buffer from cotton seed extract (CSE) medium offered a low-cost medium for fermentations. Additionally, we observed that corn steep liquor (CSL) in the medium diversified the product range with both bacteria. Maximum concentrations of ethanol, n-butanol, n-hexanol, acetic acid, butyric acid, and hexanoic acid from different fermentation treatments were 2.78 g L−1, 0.70 g L−1, 0.52 g L−1, 4.06 g L−1, 0.13 g L−1 and 0.42 g L−1, respectively. This study highlights the important role that acetogenic microbes can offer for CO2 conversion into valuable fuels and chemicals.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide