| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 243467 | Applied Energy | 2013 | 6 Pages |

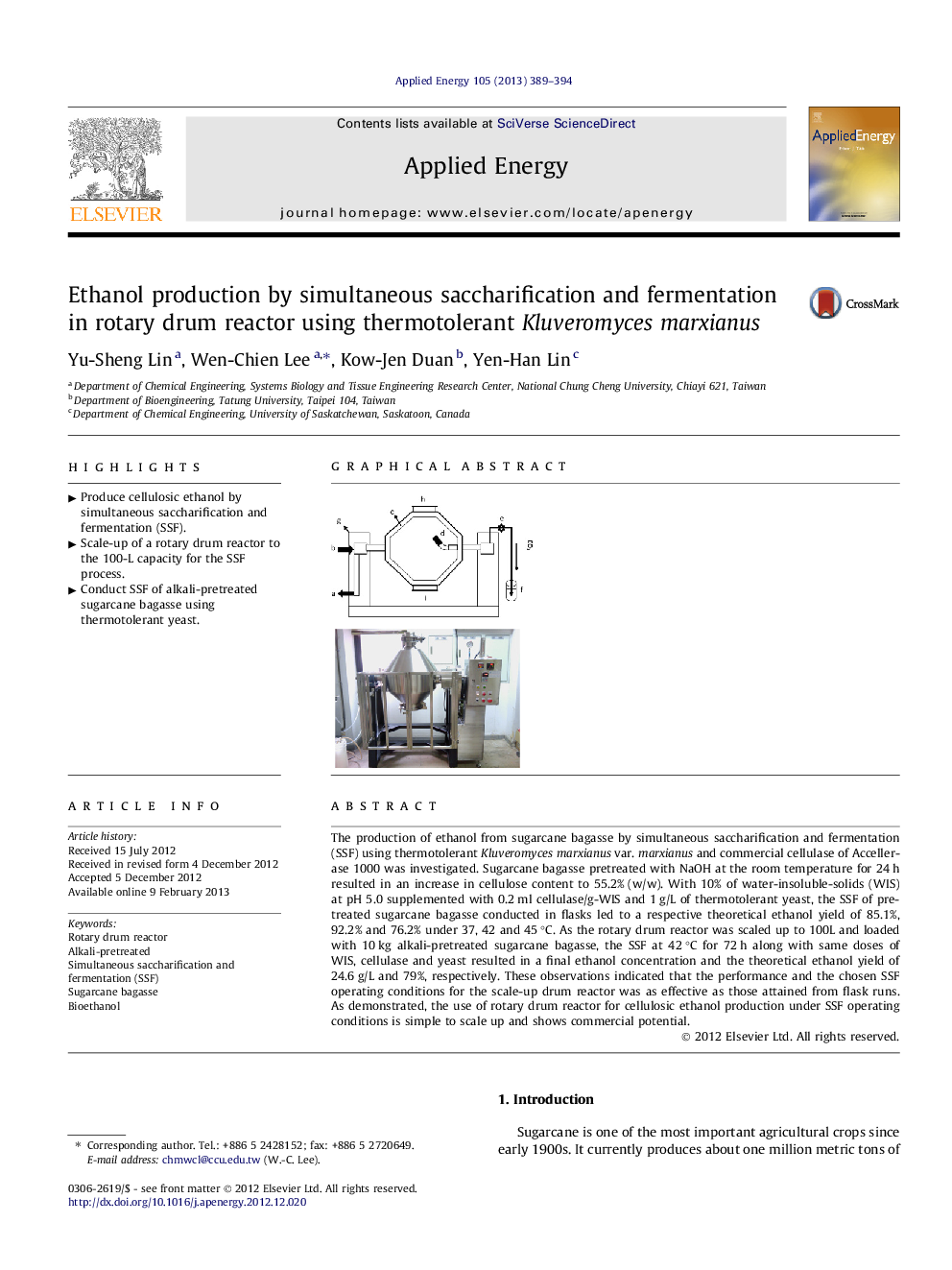

The production of ethanol from sugarcane bagasse by simultaneous saccharification and fermentation (SSF) using thermotolerant Kluveromyces marxianus var. marxianus and commercial cellulase of Accellerase 1000 was investigated. Sugarcane bagasse pretreated with NaOH at the room temperature for 24 h resulted in an increase in cellulose content to 55.2% (w/w). With 10% of water-insoluble-solids (WIS) at pH 5.0 supplemented with 0.2 ml cellulase/g-WIS and 1 g/L of thermotolerant yeast, the SSF of pretreated sugarcane bagasse conducted in flasks led to a respective theoretical ethanol yield of 85.1%, 92.2% and 76.2% under 37, 42 and 45 °C. As the rotary drum reactor was scaled up to 100L and loaded with 10 kg alkali-pretreated sugarcane bagasse, the SSF at 42 °C for 72 h along with same doses of WIS, cellulase and yeast resulted in a final ethanol concentration and the theoretical ethanol yield of 24.6 g/L and 79%, respectively. These observations indicated that the performance and the chosen SSF operating conditions for the scale-up drum reactor was as effective as those attained from flask runs. As demonstrated, the use of rotary drum reactor for cellulosic ethanol production under SSF operating conditions is simple to scale up and shows commercial potential.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slideHighlights► Produce cellulosic ethanol by simultaneous saccharification and fermentation (SSF). ► Scale-up of a rotary drum reactor to the 100-L capacity for the SSF process. ► Conduct SSF of alkali-pretreated sugarcane bagasse using thermotolerant yeast.