| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 4985532 | Journal of Colloid and Interface Science | 2016 | 7 Pages |

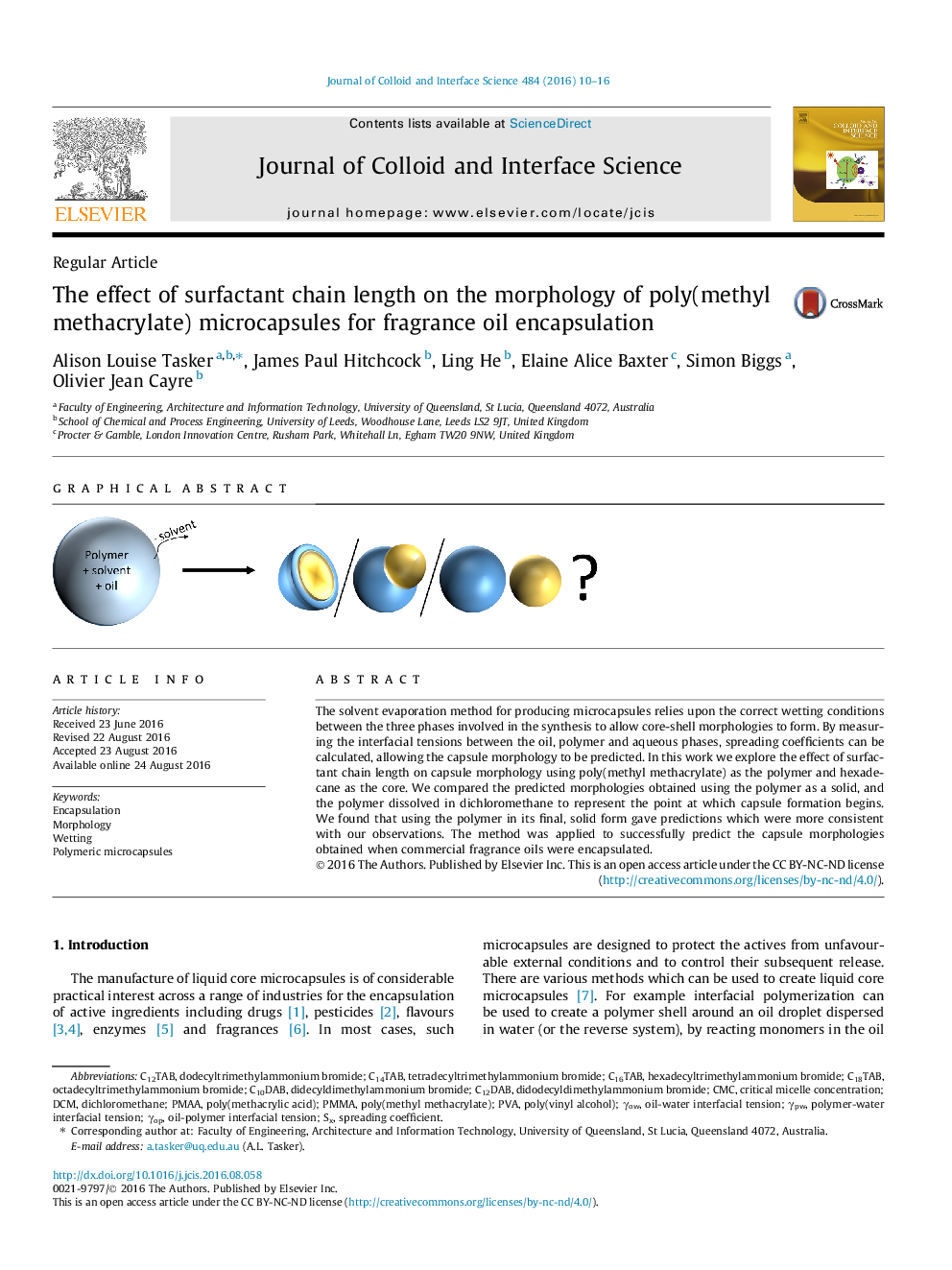

The solvent evaporation method for producing microcapsules relies upon the correct wetting conditions between the three phases involved in the synthesis to allow core-shell morphologies to form. By measuring the interfacial tensions between the oil, polymer and aqueous phases, spreading coefficients can be calculated, allowing the capsule morphology to be predicted. In this work we explore the effect of surfactant chain length on capsule morphology using poly(methyl methacrylate) as the polymer and hexadecane as the core. We compared the predicted morphologies obtained using the polymer as a solid, and the polymer dissolved in dichloromethane to represent the point at which capsule formation begins. We found that using the polymer in its final, solid form gave predictions which were more consistent with our observations. The method was applied to successfully predict the capsule morphologies obtained when commercial fragrance oils were encapsulated.

Graphical abstractDownload high-res image (41KB)Download full-size image