| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 592101 | Colloids and Surfaces A: Physicochemical and Engineering Aspects | 2015 | 10 Pages |

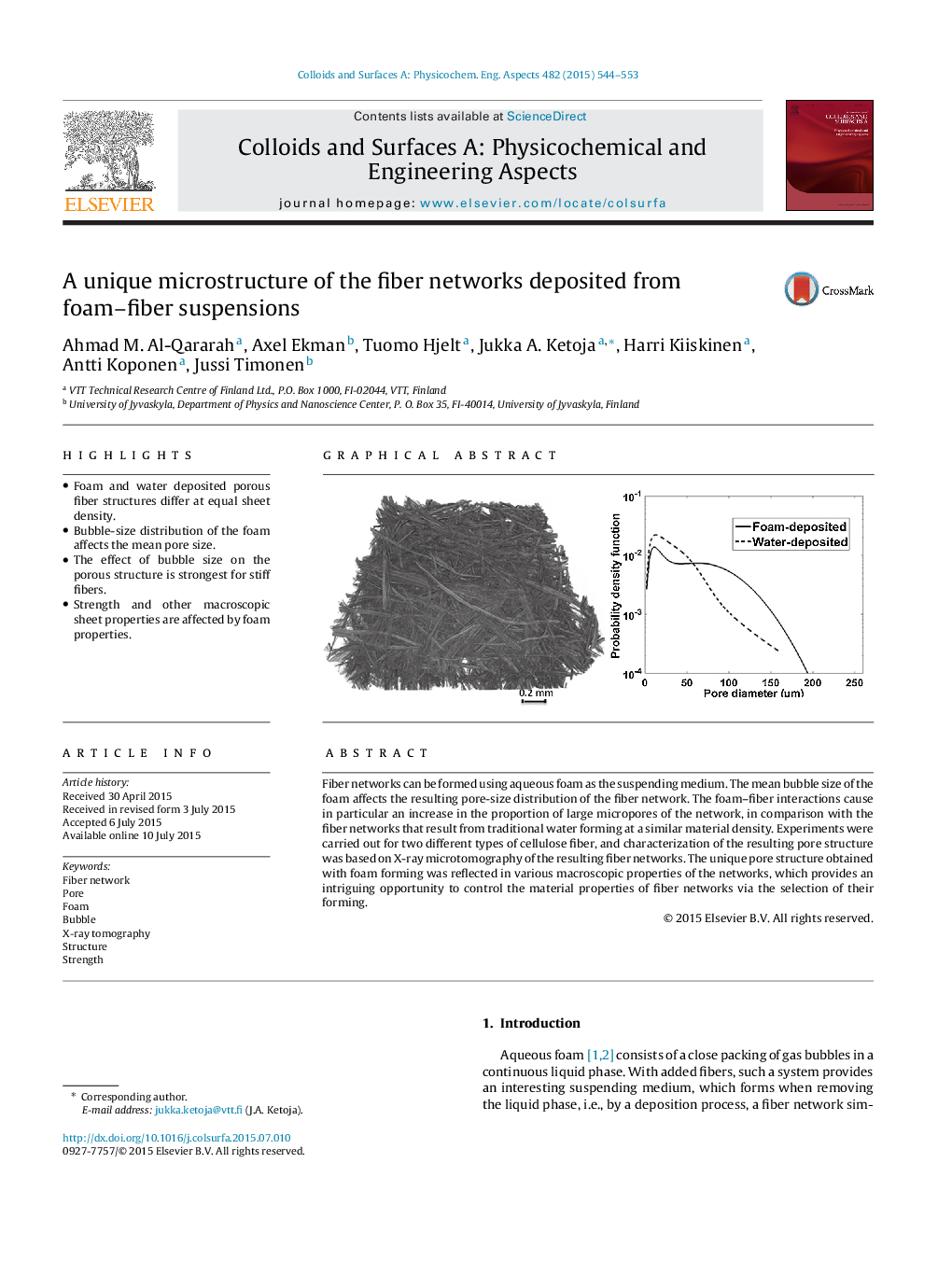

•Foam and water deposited porous fiber structures differ at equal sheet density.•Bubble-size distribution of the foam affects the mean pore size.•The effect of bubble size on the porous structure is strongest for stiff fibers.•Strength and other macroscopic sheet properties are affected by foam properties.

Fiber networks can be formed using aqueous foam as the suspending medium. The mean bubble size of the foam affects the resulting pore-size distribution of the fiber network. The foam–fiber interactions cause in particular an increase in the proportion of large micropores of the network, in comparison with the fiber networks that result from traditional water forming at a similar material density. Experiments were carried out for two different types of cellulose fiber, and characterization of the resulting pore structure was based on X-ray microtomography of the resulting fiber networks. The unique pore structure obtained with foam forming was reflected in various macroscopic properties of the networks, which provides an intriguing opportunity to control the material properties of fiber networks via the selection of their forming.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide