| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 592707 | Colloids and Surfaces A: Physicochemical and Engineering Aspects | 2014 | 9 Pages |

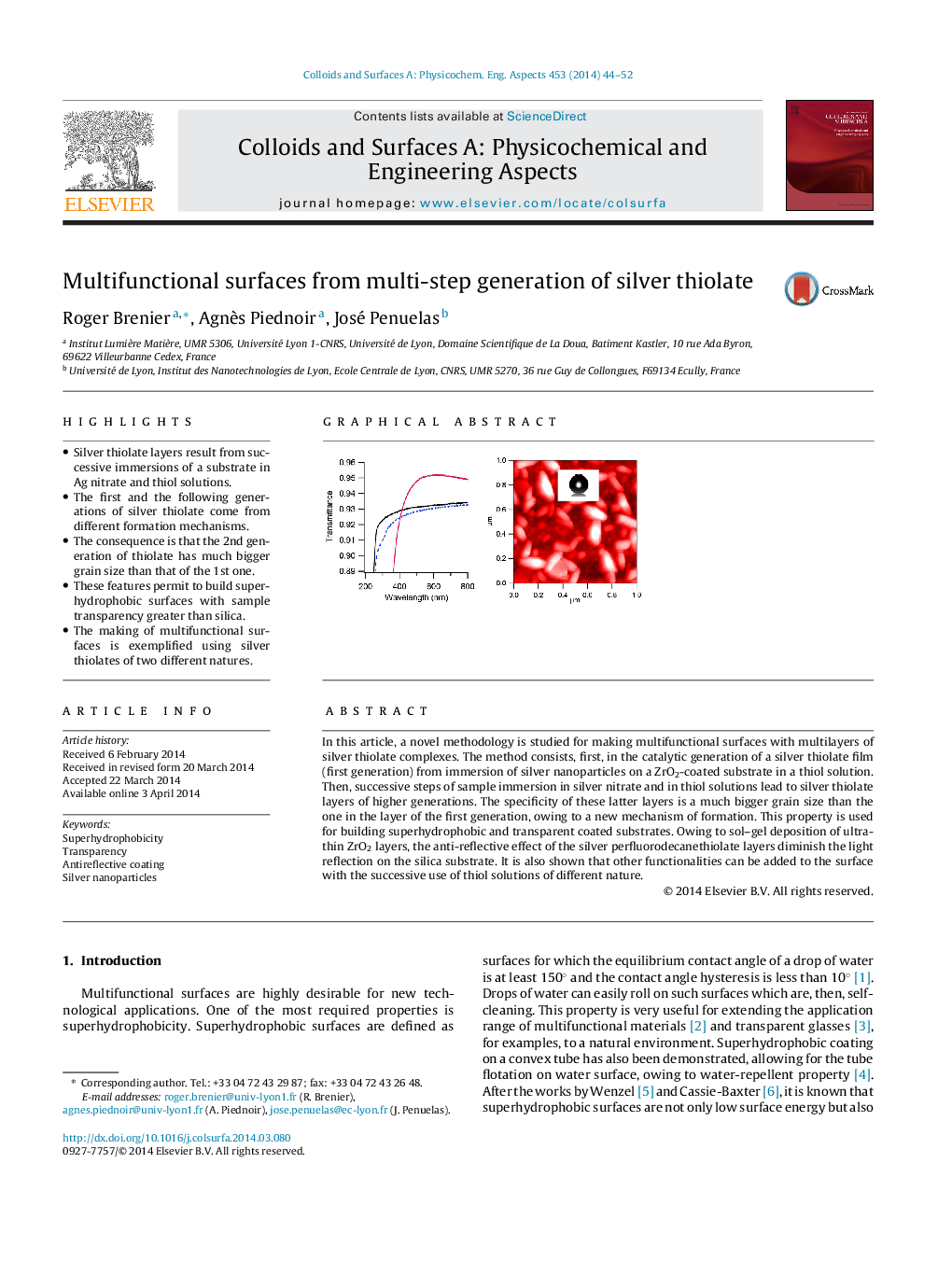

•Silver thiolate layers result from successive immersions of a substrate in Ag nitrate and thiol solutions.•The first and the following generations of silver thiolate come from different formation mechanisms.•The consequence is that the 2nd generation of thiolate has much bigger grain size than that of the 1st one.•These features permit to build superhydrophobic surfaces with sample transparency greater than silica.•The making of multifunctional surfaces is exemplified using silver thiolates of two different natures.

In this article, a novel methodology is studied for making multifunctional surfaces with multilayers of silver thiolate complexes. The method consists, first, in the catalytic generation of a silver thiolate film (first generation) from immersion of silver nanoparticles on a ZrO2-coated substrate in a thiol solution. Then, successive steps of sample immersion in silver nitrate and in thiol solutions lead to silver thiolate layers of higher generations. The specificity of these latter layers is a much bigger grain size than the one in the layer of the first generation, owing to a new mechanism of formation. This property is used for building superhydrophobic and transparent coated substrates. Owing to sol–gel deposition of ultra-thin ZrO2 layers, the anti-reflective effect of the silver perfluorodecanethiolate layers diminish the light reflection on the silica substrate. It is also shown that other functionalities can be added to the surface with the successive use of thiol solutions of different nature.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide