| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 593735 | Colloids and Surfaces A: Physicochemical and Engineering Aspects | 2013 | 7 Pages |

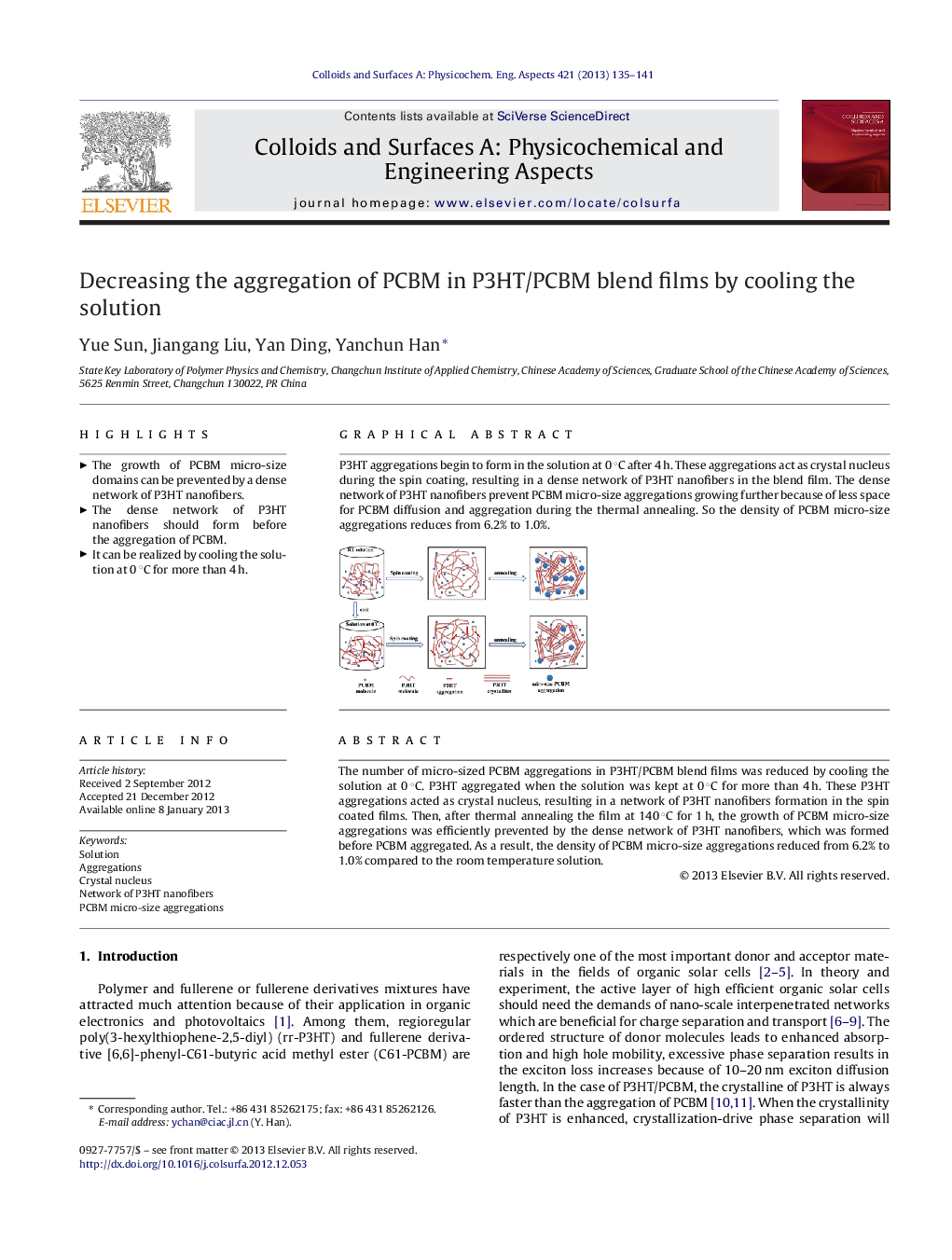

The number of micro-sized PCBM aggregations in P3HT/PCBM blend films was reduced by cooling the solution at 0 °C. P3HT aggregated when the solution was kept at 0 °C for more than 4 h. These P3HT aggregations acted as crystal nucleus, resulting in a network of P3HT nanofibers formation in the spin coated films. Then, after thermal annealing the film at 140 °C for 1 h, the growth of PCBM micro-size aggregations was efficiently prevented by the dense network of P3HT nanofibers, which was formed before PCBM aggregated. As a result, the density of PCBM micro-size aggregations reduced from 6.2% to 1.0% compared to the room temperature solution.

Graphical abstractP3HT aggregations begin to form in the solution at 0 °C after 4 h. These aggregations act as crystal nucleus during the spin coating, resulting in a dense network of P3HT nanofibers in the blend film. The dense network of P3HT nanofibers prevent PCBM micro-size aggregations growing further because of less space for PCBM diffusion and aggregation during the thermal annealing. So the density of PCBM micro-size aggregations reduces from 6.2% to 1.0%.Figure optionsDownload full-size imageDownload as PowerPoint slideHighlights► The growth of PCBM micro-size domains can be prevented by a dense network of P3HT nanofibers. ► The dense network of P3HT nanofibers should form before the aggregation of PCBM. ► It can be realized by cooling the solution at 0 °C for more than 4 h.