| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 593765 | Colloids and Surfaces A: Physicochemical and Engineering Aspects | 2013 | 7 Pages |

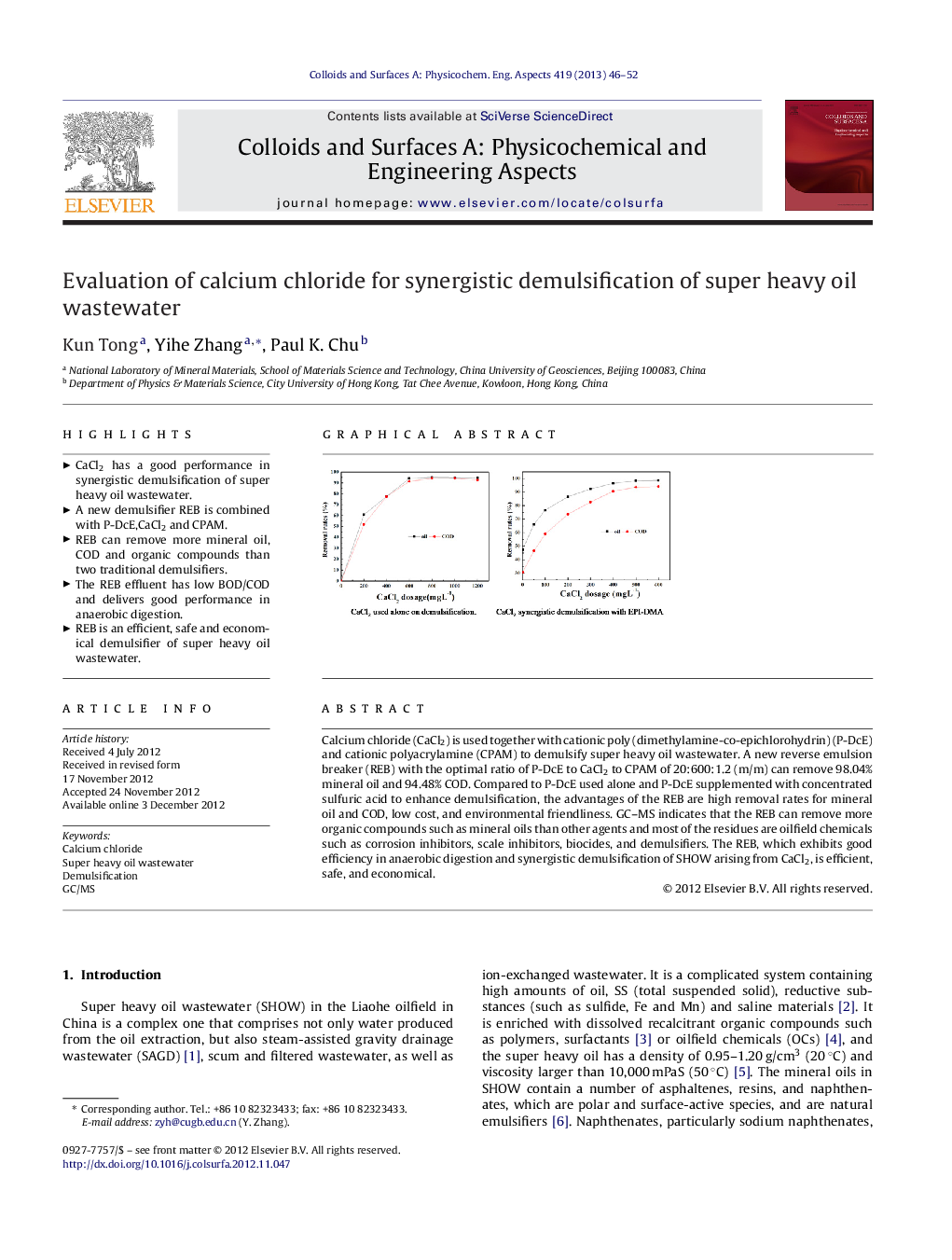

Calcium chloride (CaCl2) is used together with cationic poly (dimethylamine-co-epichlorohydrin) (P-DcE) and cationic polyacrylamine (CPAM) to demulsify super heavy oil wastewater. A new reverse emulsion breaker (REB) with the optimal ratio of P-DcE to CaCl2 to CPAM of 20:600:1.2 (m/m) can remove 98.04% mineral oil and 94.48% COD. Compared to P-DcE used alone and P-DcE supplemented with concentrated sulfuric acid to enhance demulsification, the advantages of the REB are high removal rates for mineral oil and COD, low cost, and environmental friendliness. GC–MS indicates that the REB can remove more organic compounds such as mineral oils than other agents and most of the residues are oilfield chemicals such as corrosion inhibitors, scale inhibitors, biocides, and demulsifiers. The REB, which exhibits good efficiency in anaerobic digestion and synergistic demulsification of SHOW arising from CaCl2, is efficient, safe, and economical.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slideHighlights► CaCl2 has a good performance in synergistic demulsification of super heavy oil wastewater. ► A new demulsifier REB is combined with P-DcE,CaCl2 and CPAM. ► REB can remove more mineral oil, COD and organic compounds than two traditional demulsifiers. ► The REB effluent has low BOD/COD and delivers good performance in anaerobic digestion. ► REB is an efficient, safe and economical demulsifier of super heavy oil wastewater.