| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 593978 | Colloids and Surfaces A: Physicochemical and Engineering Aspects | 2012 | 6 Pages |

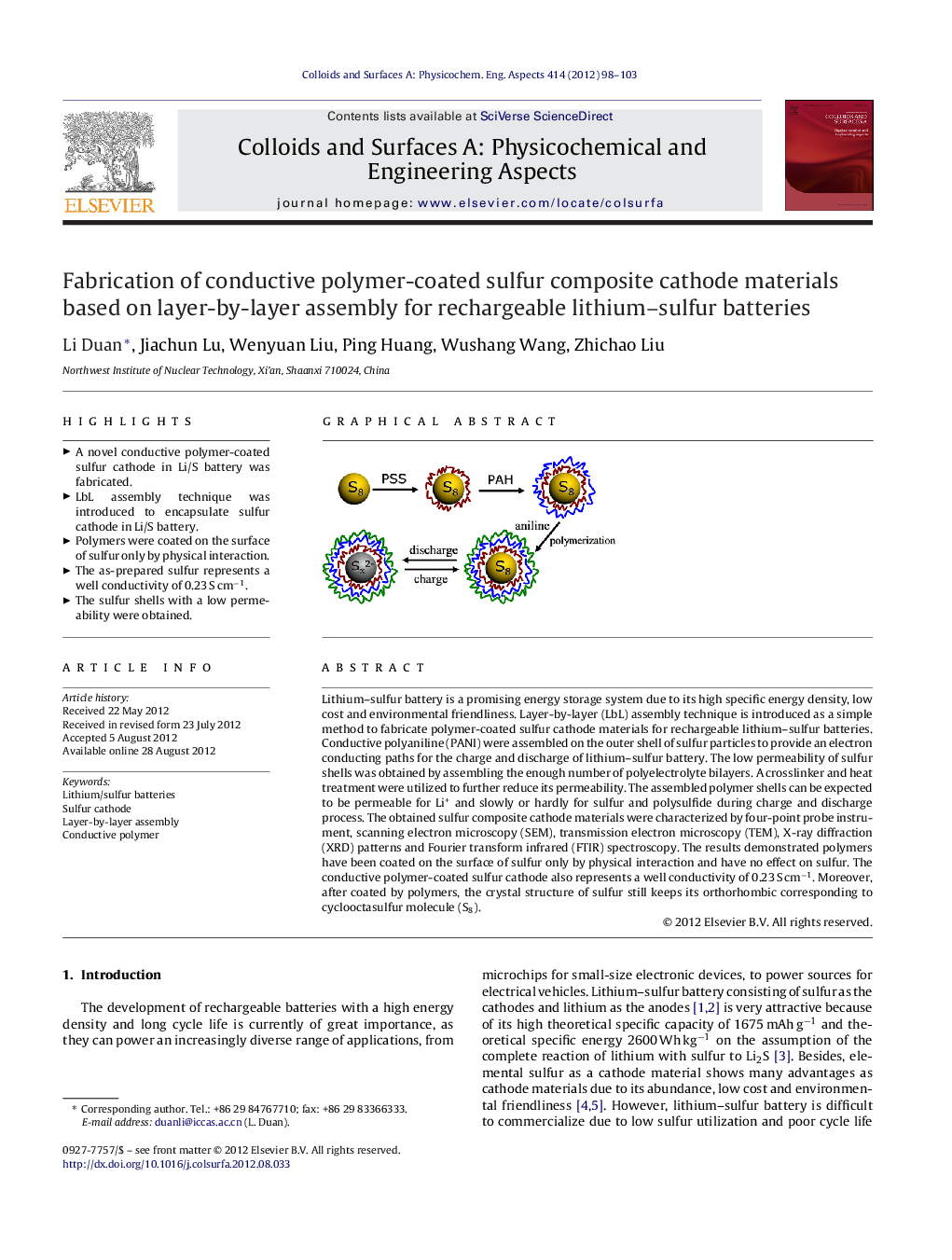

Lithium–sulfur battery is a promising energy storage system due to its high specific energy density, low cost and environmental friendliness. Layer-by-layer (LbL) assembly technique is introduced as a simple method to fabricate polymer-coated sulfur cathode materials for rechargeable lithium–sulfur batteries. Conductive polyaniline (PANI) were assembled on the outer shell of sulfur particles to provide an electron conducting paths for the charge and discharge of lithium–sulfur battery. The low permeability of sulfur shells was obtained by assembling the enough number of polyelectrolyte bilayers. A crosslinker and heat treatment were utilized to further reduce its permeability. The assembled polymer shells can be expected to be permeable for Li+ and slowly or hardly for sulfur and polysulfide during charge and discharge process. The obtained sulfur composite cathode materials were characterized by four-point probe instrument, scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD) patterns and Fourier transform infrared (FTIR) spectroscopy. The results demonstrated polymers have been coated on the surface of sulfur only by physical interaction and have no effect on sulfur. The conductive polymer-coated sulfur cathode also represents a well conductivity of 0.23 S cm−1. Moreover, after coated by polymers, the crystal structure of sulfur still keeps its orthorhombic corresponding to cyclooctasulfur molecule (S8).

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slideHighlights► A novel conductive polymer-coated sulfur cathode in Li/S battery was fabricated. ► LbL assembly technique was introduced to encapsulate sulfur cathode in Li/S battery. ► Polymers were coated on the surface of sulfur only by physical interaction. ► The as-prepared sulfur represents a well conductivity of 0.23 S cm−1. ► The sulfur shells with a low permeability were obtained.