| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 606382 | Journal of Colloid and Interface Science | 2016 | 8 Pages |

•A centrifugal microfluidic chip was developed for producing alginate particles.•The chip-based system has substantial advantages in simplification and reliability.•High throughput production was achieved by increasing the number of microchannels.

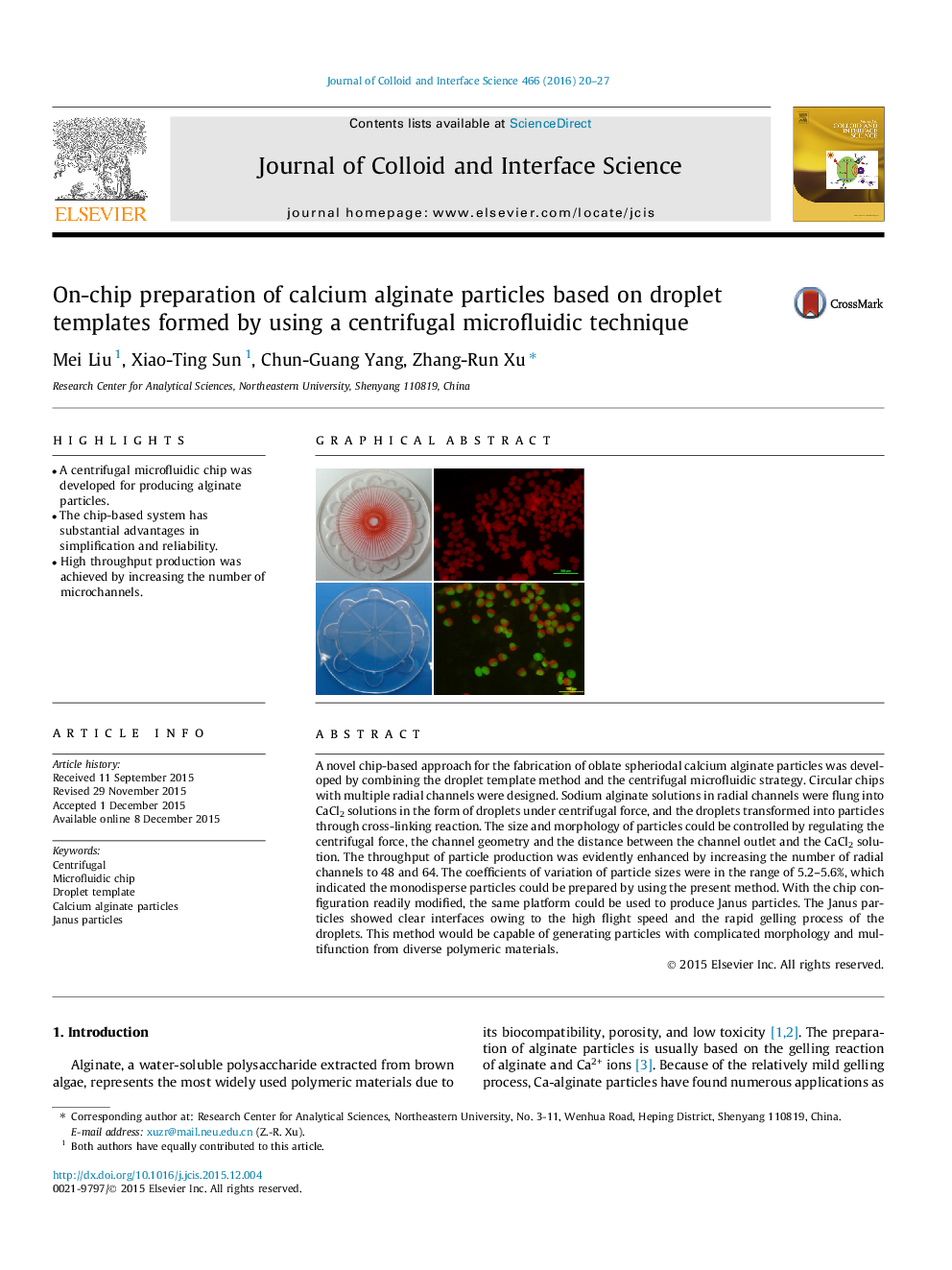

A novel chip-based approach for the fabrication of oblate spheriodal calcium alginate particles was developed by combining the droplet template method and the centrifugal microfluidic strategy. Circular chips with multiple radial channels were designed. Sodium alginate solutions in radial channels were flung into CaCl2 solutions in the form of droplets under centrifugal force, and the droplets transformed into particles through cross-linking reaction. The size and morphology of particles could be controlled by regulating the centrifugal force, the channel geometry and the distance between the channel outlet and the CaCl2 solution. The throughput of particle production was evidently enhanced by increasing the number of radial channels to 48 and 64. The coefficients of variation of particle sizes were in the range of 5.2–5.6%, which indicated the monodisperse particles could be prepared by using the present method. With the chip configuration readily modified, the same platform could be used to produce Janus particles. The Janus particles showed clear interfaces owing to the high flight speed and the rapid gelling process of the droplets. This method would be capable of generating particles with complicated morphology and multifunction from diverse polymeric materials.

Graphical abstractFigure optionsDownload full-size imageDownload high-quality image (125 K)Download as PowerPoint slide