| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 608532 | Journal of Colloid and Interface Science | 2011 | 7 Pages |

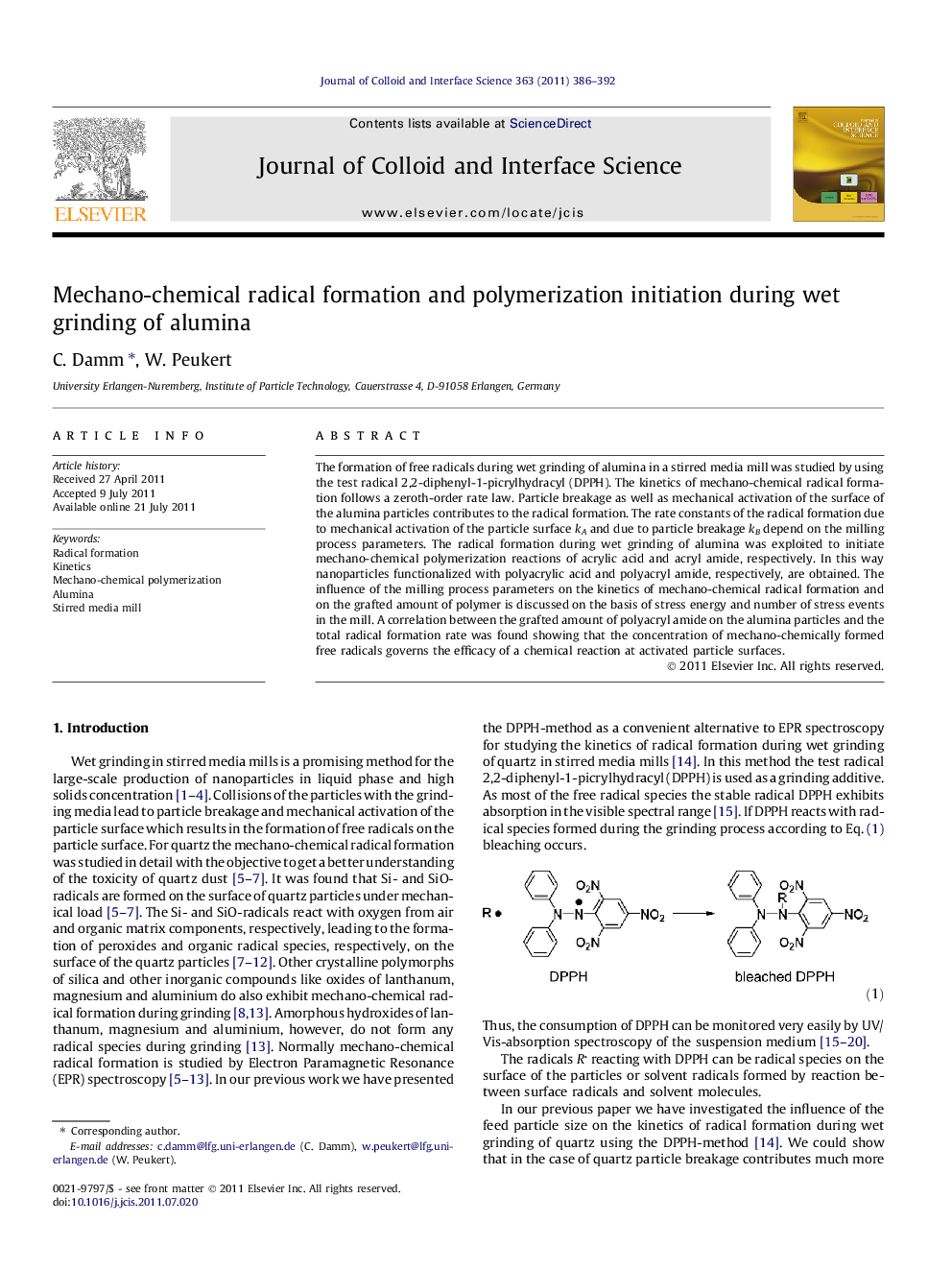

The formation of free radicals during wet grinding of alumina in a stirred media mill was studied by using the test radical 2,2-diphenyl-1-picrylhydracyl (DPPH). The kinetics of mechano-chemical radical formation follows a zeroth-order rate law. Particle breakage as well as mechanical activation of the surface of the alumina particles contributes to the radical formation. The rate constants of the radical formation due to mechanical activation of the particle surface kA and due to particle breakage kB depend on the milling process parameters. The radical formation during wet grinding of alumina was exploited to initiate mechano-chemical polymerization reactions of acrylic acid and acryl amide, respectively. In this way nanoparticles functionalized with polyacrylic acid and polyacryl amide, respectively, are obtained. The influence of the milling process parameters on the kinetics of mechano-chemical radical formation and on the grafted amount of polymer is discussed on the basis of stress energy and number of stress events in the mill. A correlation between the grafted amount of polyacryl amide on the alumina particles and the total radical formation rate was found showing that the concentration of mechano-chemically formed free radicals governs the efficacy of a chemical reaction at activated particle surfaces.

Graphical abstractGrinding of alumina in stirred media mills leads to the formation of free radicals. The mechano-chemically formed free radicals react with the scavenger DPPH leading to bleaching of the DPPH solution. Thus, the consumption of DPPH and therefore the kinetics of radical formation can be monitored by UV/Vis-spectroscopy.Figure optionsDownload full-size imageDownload high-quality image (76 K)Download as PowerPoint slideHighlights► Kinetics of mechano-chemical radical formation during wet grinding of alumina. ► Polymerization initiation by mechano-chemically formed free radicals. ► Correlation between grafted amount of polymer and rate of radical formation. ► Milling process parameters influence kinetics of radical formation and polymer grafting yield.