| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 644487 | Applied Thermal Engineering | 2016 | 7 Pages |

•A flat disk-shaped evaporator with a shared compensation chamber is put forward.•The evaporator heat transfer capacity increases from 210 W for one heating surface to 240 W for two heating surfaces.•The loop demonstrates a good response to alternative heat load applied to two heating surfaces.•The co-evaporation of two primary wicks enhances the operating performance of the LHP.

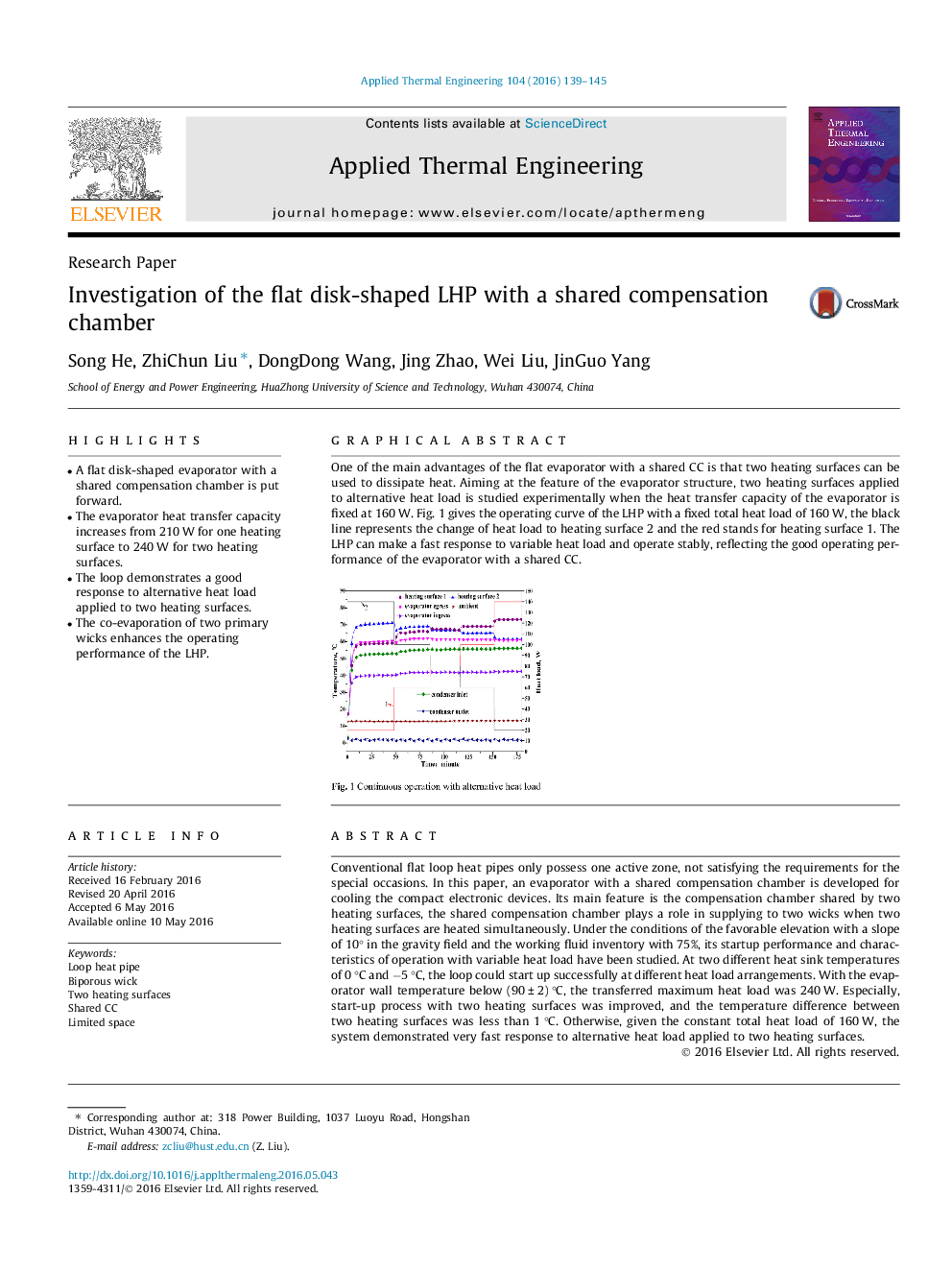

Conventional flat loop heat pipes only possess one active zone, not satisfying the requirements for the special occasions. In this paper, an evaporator with a shared compensation chamber is developed for cooling the compact electronic devices. Its main feature is the compensation chamber shared by two heating surfaces, the shared compensation chamber plays a role in supplying to two wicks when two heating surfaces are heated simultaneously. Under the conditions of the favorable elevation with a slope of 10° in the gravity field and the working fluid inventory with 75%, its startup performance and characteristics of operation with variable heat load have been studied. At two different heat sink temperatures of 0 °C and −5 °C, the loop could start up successfully at different heat load arrangements. With the evaporator wall temperature below (90 ± 2) °C, the transferred maximum heat load was 240 W. Especially, start-up process with two heating surfaces was improved, and the temperature difference between two heating surfaces was less than 1 °C. Otherwise, given the constant total heat load of 160 W, the system demonstrated very fast response to alternative heat load applied to two heating surfaces.

Graphical abstractOne of the main advantages of the flat evaporator with a shared CC is that two heating surfaces can be used to dissipate heat. Aiming at the feature of the evaporator structure, two heating surfaces applied to alternative heat load is studied experimentally when the heat transfer capacity of the evaporator is fixed at 160 W. Fig. 1 gives the operating curve of the LHP with a fixed total heat load of 160 W, the black line represents the change of heat load to heating surface 2 and the red stands for heating surface 1. The LHP can make a fast response to variable heat load and operate stably, reflecting the good operating performance of the evaporator with a shared CC.Figure optionsDownload full-size imageDownload as PowerPoint slide