| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 644573 | Applied Thermal Engineering | 2016 | 10 Pages |

•Intermediate heating proposed to adapt pipelines for transport of heavier oils.•Viscosity is reduced and significant savings in throughput can be achieved.•A flexible modelling framework to simulate oil pipelines is presented.•Concept illustrated in a case study of a 300 km section of the Russia-China pipeline.•Incremental addition and relocation of the heat duty using modular heating stations.

Pipelines that were well designed for conventional oils may not be able to cope with a transition to heavy oils without some retrofit adaptation, as the increased pressure drop may exceed constraints and force some reduction in throughput. In this paper, ways of enhancing the utilization of existing, capital intensive infrastructure by small, incremental additions are explored. A thermo-hydraulic pipeline model for a buried pipeline is presented. The model is then applied to a case study involving a section of the important, recently built Russia-China ESPO pipeline, for which a gradual shift from the current (design) light oil to heavier oils is considered. A number of thermal retrofit scenarios are proposed and assessed which involve the incremental supply of additional heat at selected points. These scenarios go from pre-heating of the oil at entrance to use of single and multiple intermediate heating stations. The heating duty requirements for each case are calculated. The results show that a careful use of such thermal management techniques can significantly mitigate the reduction in throughput that would otherwise be required, leading to significant economic savings in operations. It is highlighted that the development of adaptable, modular low-cost heating technologies would make this approach significantly advantageous over other alternatives.

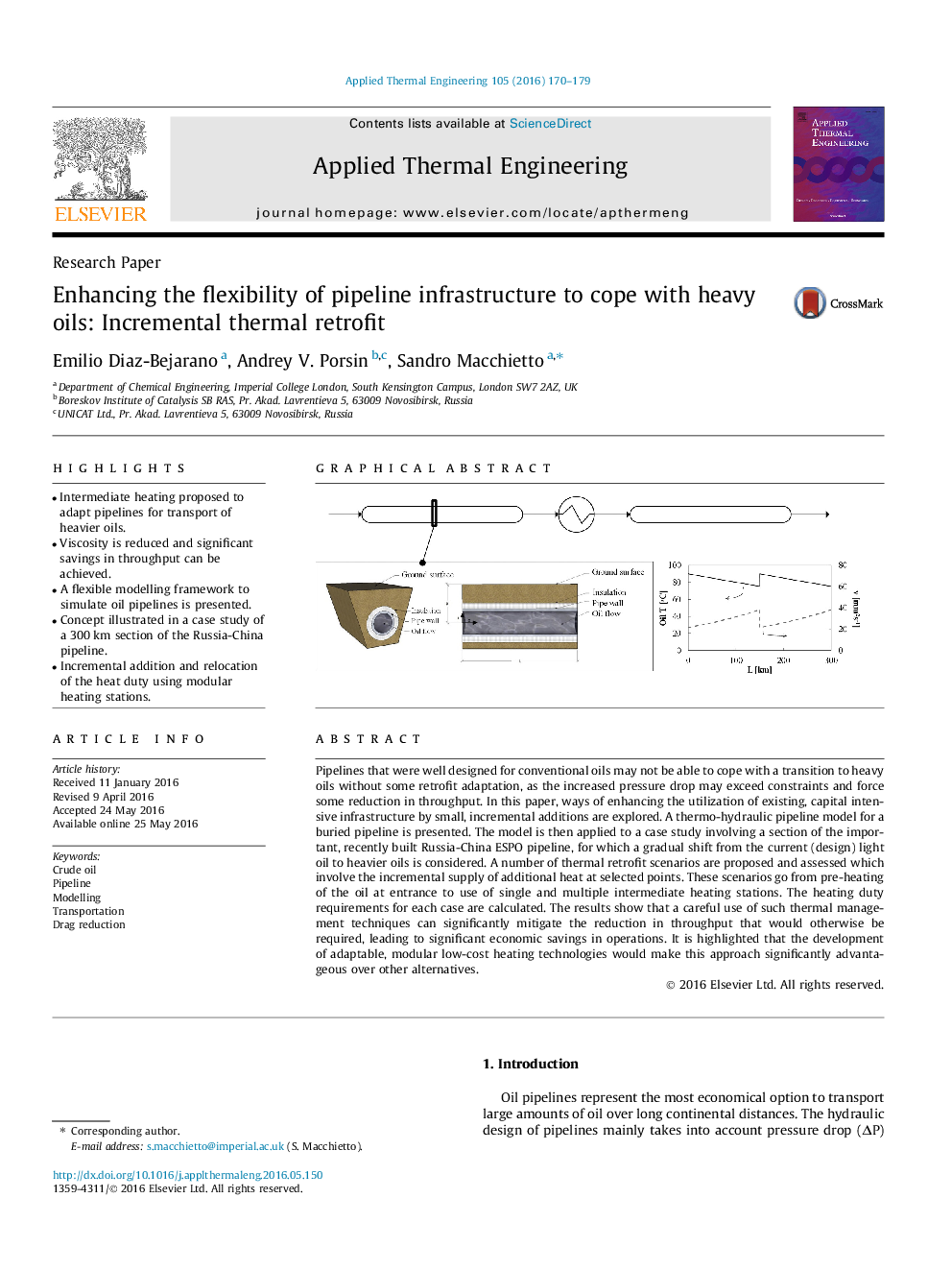

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide