| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 645064 | Applied Thermal Engineering | 2015 | 8 Pages |

•A novel integrated plug-chip spray cooling enclosure was designed for workstation.•Spray inclination angle affects response time and fastest time is obtained at 90°.•The inclination angle and flow rate have effect on heat transfer in enclosure.•Optimal heat transfer performance is obtained at 75°.•Maximum heat flux reaches 79.1 W/cm2 with PF5060 while 81.6 W/cm2 with HFE7100.

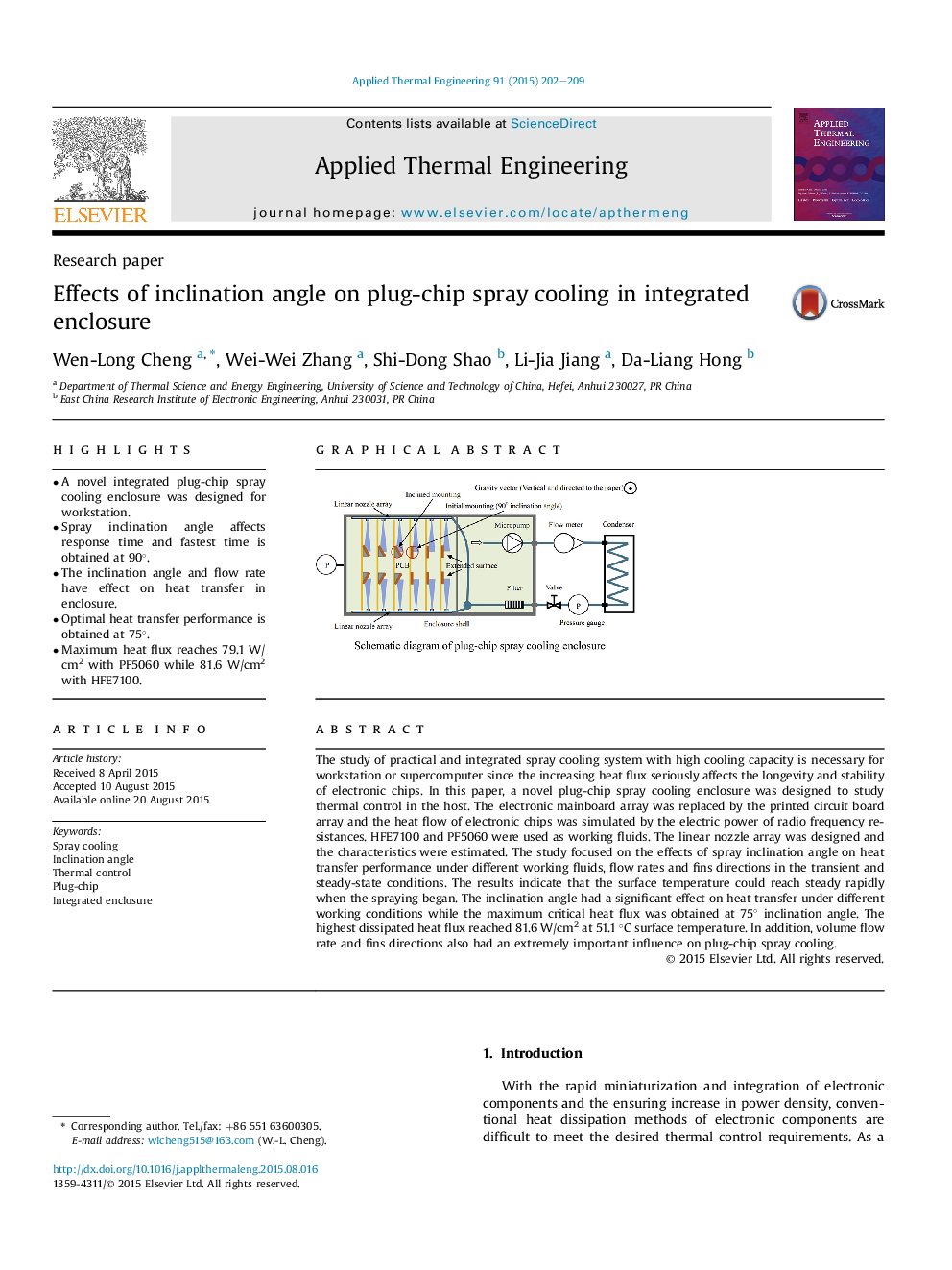

The study of practical and integrated spray cooling system with high cooling capacity is necessary for workstation or supercomputer since the increasing heat flux seriously affects the longevity and stability of electronic chips. In this paper, a novel plug-chip spray cooling enclosure was designed to study thermal control in the host. The electronic mainboard array was replaced by the printed circuit board array and the heat flow of electronic chips was simulated by the electric power of radio frequency resistances. HFE7100 and PF5060 were used as working fluids. The linear nozzle array was designed and the characteristics were estimated. The study focused on the effects of spray inclination angle on heat transfer performance under different working fluids, flow rates and fins directions in the transient and steady-state conditions. The results indicate that the surface temperature could reach steady rapidly when the spraying began. The inclination angle had a significant effect on heat transfer under different working conditions while the maximum critical heat flux was obtained at 75° inclination angle. The highest dissipated heat flux reached 81.6 W/cm2 at 51.1 °C surface temperature. In addition, volume flow rate and fins directions also had an extremely important influence on plug-chip spray cooling.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide