| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6478605 | Applied Energy | 2017 | 11 Pages |

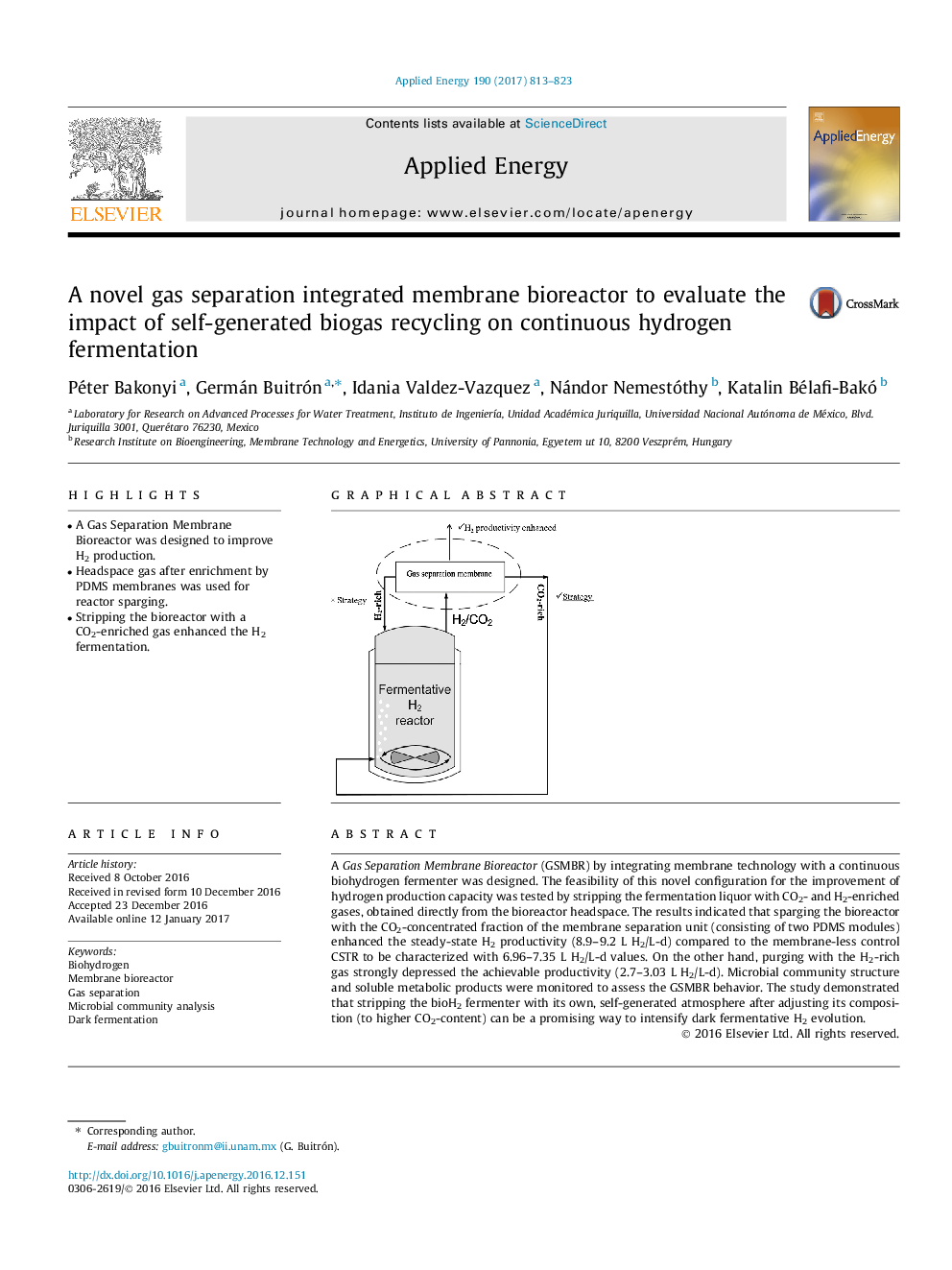

â¢A Gas Separation Membrane Bioreactor was designed to improve H2 production.â¢Headspace gas after enrichment by PDMS membranes was used for reactor sparging.â¢Stripping the bioreactor with a CO2-enriched gas enhanced the H2 fermentation.

A Gas Separation Membrane Bioreactor (GSMBR) by integrating membrane technology with a continuous biohydrogen fermenter was designed. The feasibility of this novel configuration for the improvement of hydrogen production capacity was tested by stripping the fermentation liquor with CO2- and H2-enriched gases, obtained directly from the bioreactor headspace. The results indicated that sparging the bioreactor with the CO2-concentrated fraction of the membrane separation unit (consisting of two PDMS modules) enhanced the steady-state H2 productivity (8.9-9.2 L H2/L-d) compared to the membrane-less control CSTR to be characterized with 6.96-7.35 L H2/L-d values. On the other hand, purging with the H2-rich gas strongly depressed the achievable productivity (2.7-3.03 L H2/L-d). Microbial community structure and soluble metabolic products were monitored to assess the GSMBR behavior. The study demonstrated that stripping the bioH2 fermenter with its own, self-generated atmosphere after adjusting its composition (to higher CO2-content) can be a promising way to intensify dark fermentative H2 evolution.

Graphical abstractDownload high-res image (80KB)Download full-size image