| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 680151 | Bioresource Technology | 2015 | 7 Pages |

•Triple stage biotrickling filter was superior to single stage biotrickling filter.•H2S removal efficiency was enhanced by step feeding O2 rich liquid recirculation.•1st order removal rate coefficient of T-BTF was 47% higher than S-BTF.•Larger liquid recirculation shifted O2/H2S balance system to complete oxidation.•Sulfuric acid production improved with an increasing liquid recirculation velocity.

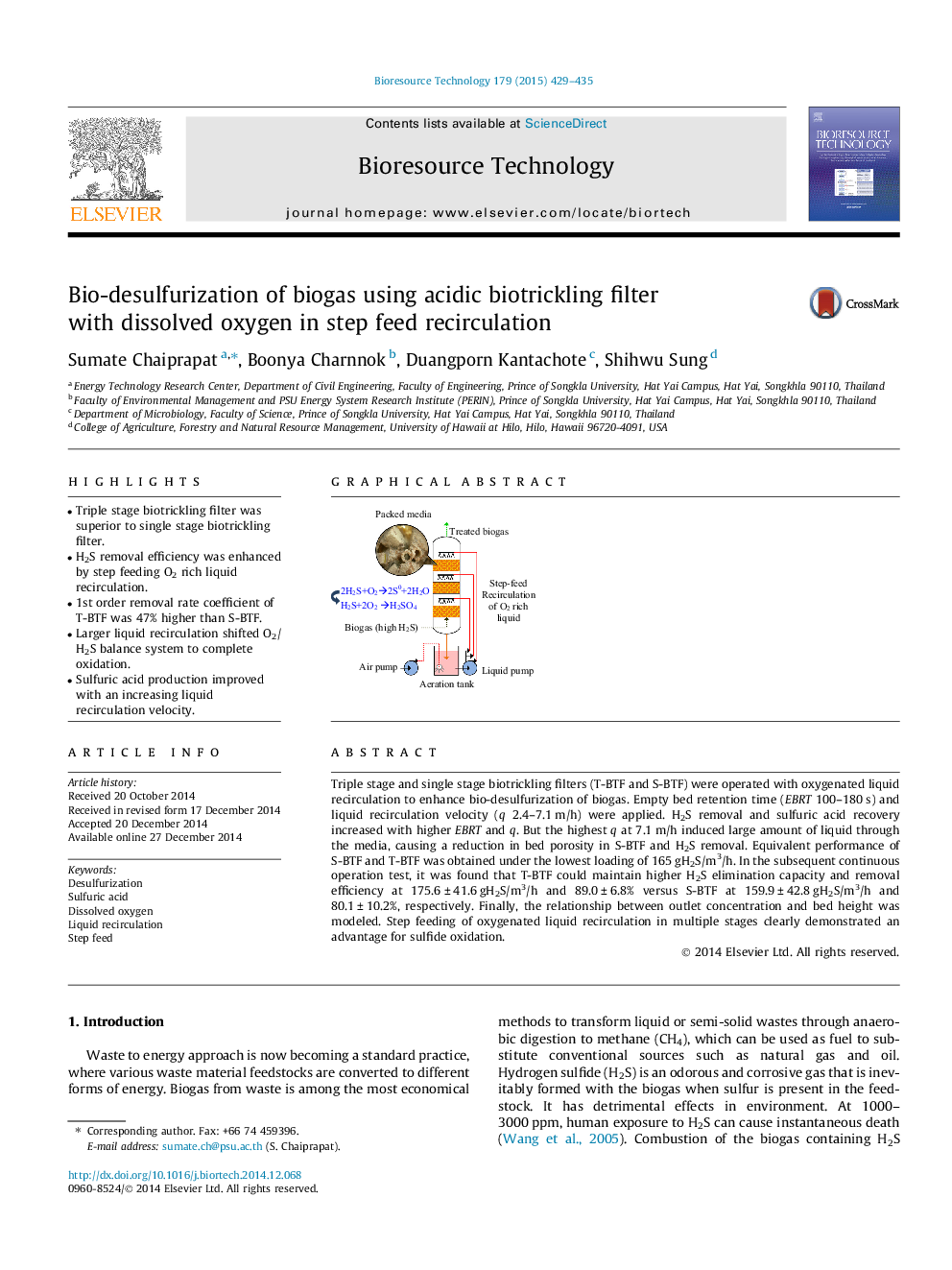

Triple stage and single stage biotrickling filters (T-BTF and S-BTF) were operated with oxygenated liquid recirculation to enhance bio-desulfurization of biogas. Empty bed retention time (EBRT 100–180 s) and liquid recirculation velocity (q 2.4–7.1 m/h) were applied. H2S removal and sulfuric acid recovery increased with higher EBRT and q. But the highest q at 7.1 m/h induced large amount of liquid through the media, causing a reduction in bed porosity in S-BTF and H2S removal. Equivalent performance of S-BTF and T-BTF was obtained under the lowest loading of 165 gH2S/m3/h. In the subsequent continuous operation test, it was found that T-BTF could maintain higher H2S elimination capacity and removal efficiency at 175.6 ± 41.6 gH2S/m3/h and 89.0 ± 6.8% versus S-BTF at 159.9 ± 42.8 gH2S/m3/h and 80.1 ± 10.2%, respectively. Finally, the relationship between outlet concentration and bed height was modeled. Step feeding of oxygenated liquid recirculation in multiple stages clearly demonstrated an advantage for sulfide oxidation.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide