| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 6979753 | Colloids and Surfaces A: Physicochemical and Engineering Aspects | 2014 | 10 Pages |

Abstract

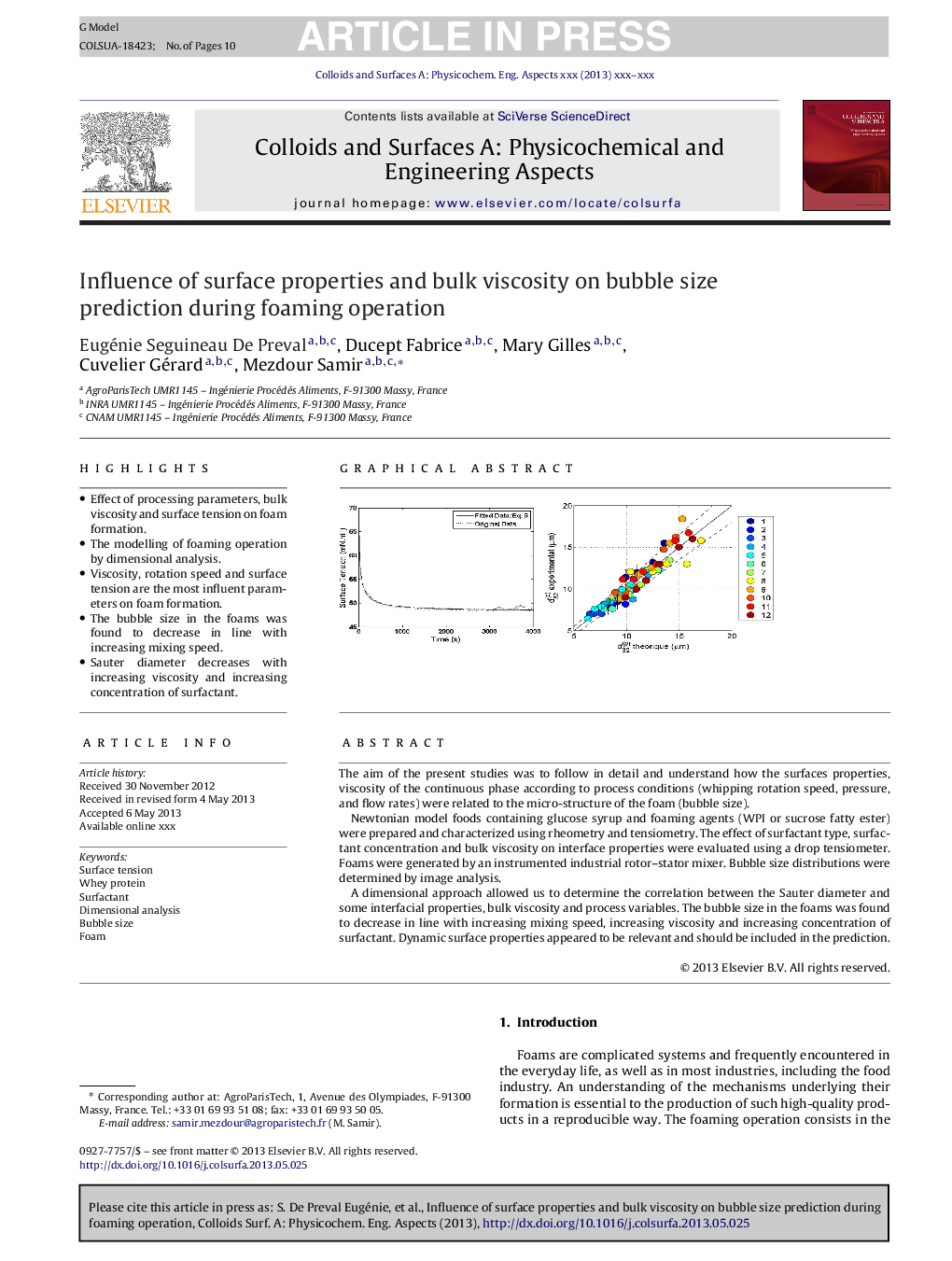

- Effect of processing parameters, bulk viscosity and surface tension on foam formation.

- The modelling of foaming operation by dimensional analysis.

- Viscosity, rotation speed and surface tension are the most influent parameters on foam formation.

- The bubble size in the foams was found to decrease in line with increasing mixing speed.

- Sauter diameter decreases with increasing viscosity and increasing concentration of surfactant.

Related Topics

Physical Sciences and Engineering

Chemical Engineering

Colloid and Surface Chemistry

Authors

Eugénie Seguineau De Preval, Ducept Fabrice, Mary Gilles, Cuvelier Gérard, Mezdour Samir,