| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 702942 | Diamond and Related Materials | 2009 | 6 Pages |

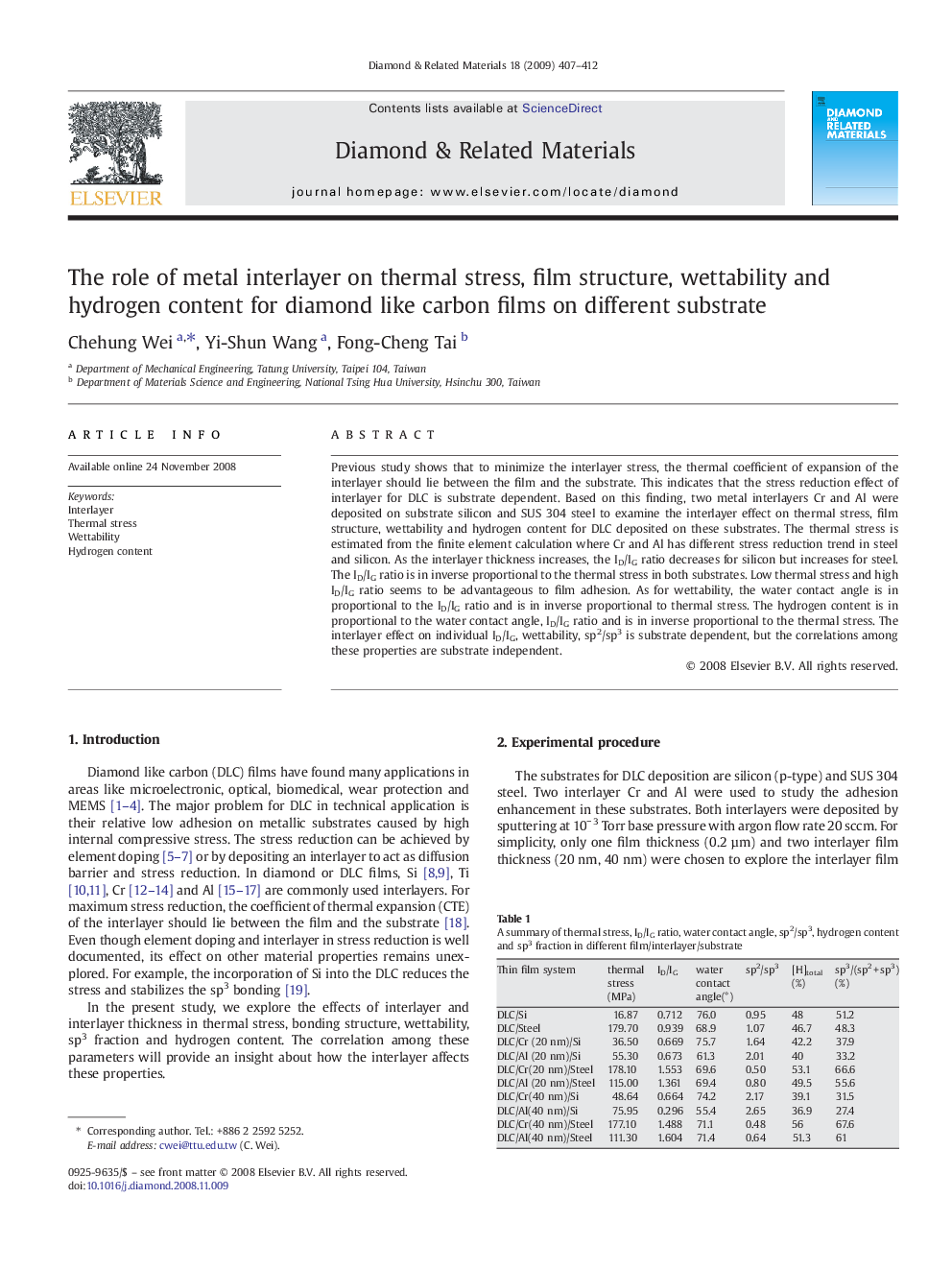

Previous study shows that to minimize the interlayer stress, the thermal coefficient of expansion of the interlayer should lie between the film and the substrate. This indicates that the stress reduction effect of interlayer for DLC is substrate dependent. Based on this finding, two metal interlayers Cr and Al were deposited on substrate silicon and SUS 304 steel to examine the interlayer effect on thermal stress, film structure, wettability and hydrogen content for DLC deposited on these substrates. The thermal stress is estimated from the finite element calculation where Cr and Al has different stress reduction trend in steel and silicon. As the interlayer thickness increases, the ID/IG ratio decreases for silicon but increases for steel. The ID/IG ratio is in inverse proportional to the thermal stress in both substrates. Low thermal stress and high ID/IG ratio seems to be advantageous to film adhesion. As for wettability, the water contact angle is in proportional to the ID/IG ratio and is in inverse proportional to thermal stress. The hydrogen content is in proportional to the water contact angle, ID/IG ratio and is in inverse proportional to the thermal stress. The interlayer effect on individual ID/IG, wettability, sp2/sp3 is substrate dependent, but the correlations among these properties are substrate independent.