| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 7047473 | Applied Thermal Engineering | 2016 | 10 Pages |

Abstract

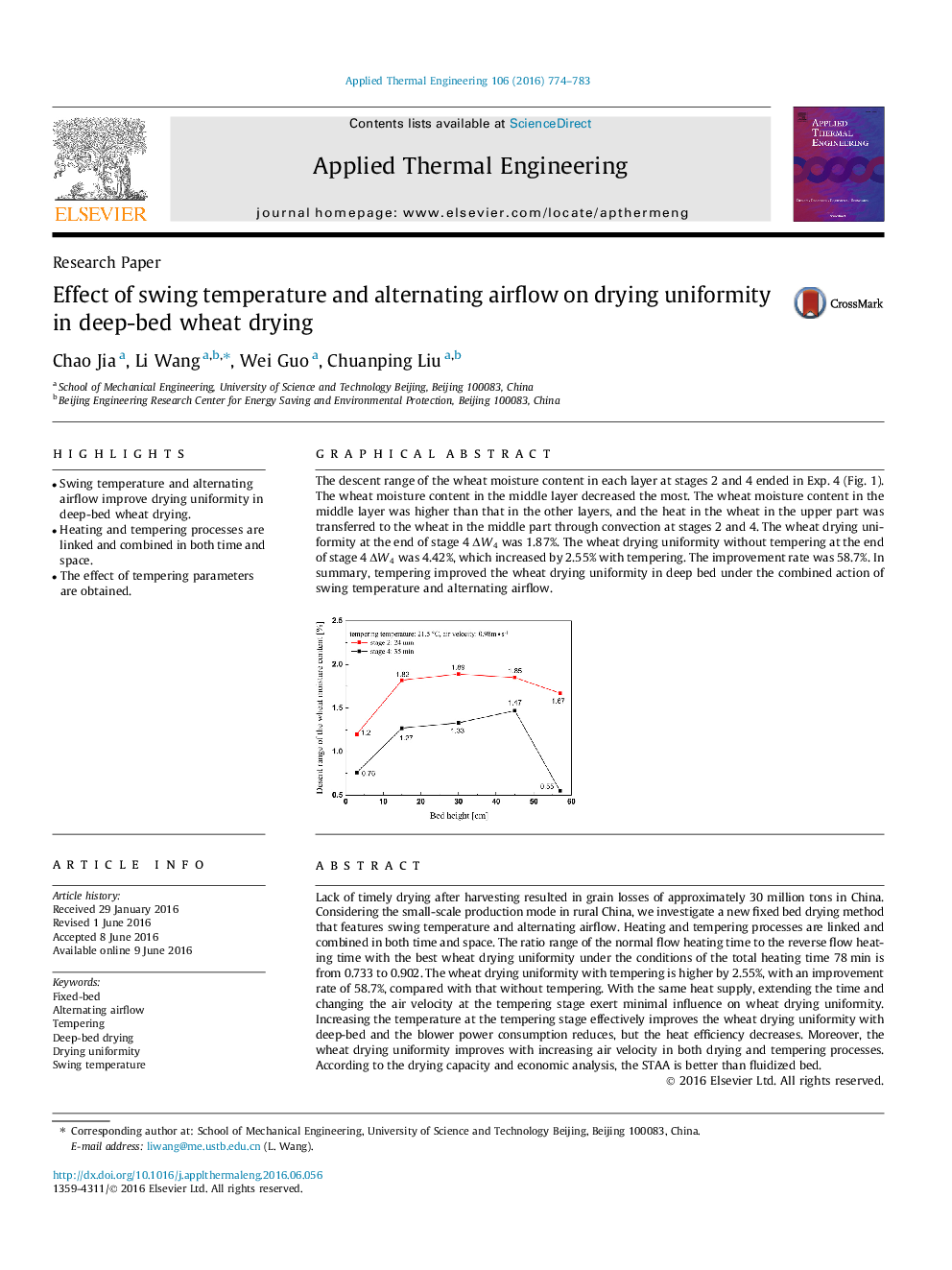

The descent range of the wheat moisture content in each layer at stages 2 and 4 ended in Exp. 4 (Fig. 1). The wheat moisture content in the middle layer decreased the most. The wheat moisture content in the middle layer was higher than that in the other layers, and the heat in the wheat in the upper part was transferred to the wheat in the middle part through convection at stages 2 and 4. The wheat drying uniformity at the end of stage 4 ÎW4 was 1.87%. The wheat drying uniformity without tempering at the end of stage 4 ÎW4 was 4.42%, which increased by 2.55% with tempering. The improvement rate was 58.7%. In summary, tempering improved the wheat drying uniformity in deep bed under the combined action of swing temperature and alternating airflow.86

Related Topics

Physical Sciences and Engineering

Chemical Engineering

Fluid Flow and Transfer Processes

Authors

Chao Jia, Li Wang, Wei Guo, Chuanping Liu,