| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1284269 | Journal of Power Sources | 2014 | 10 Pages |

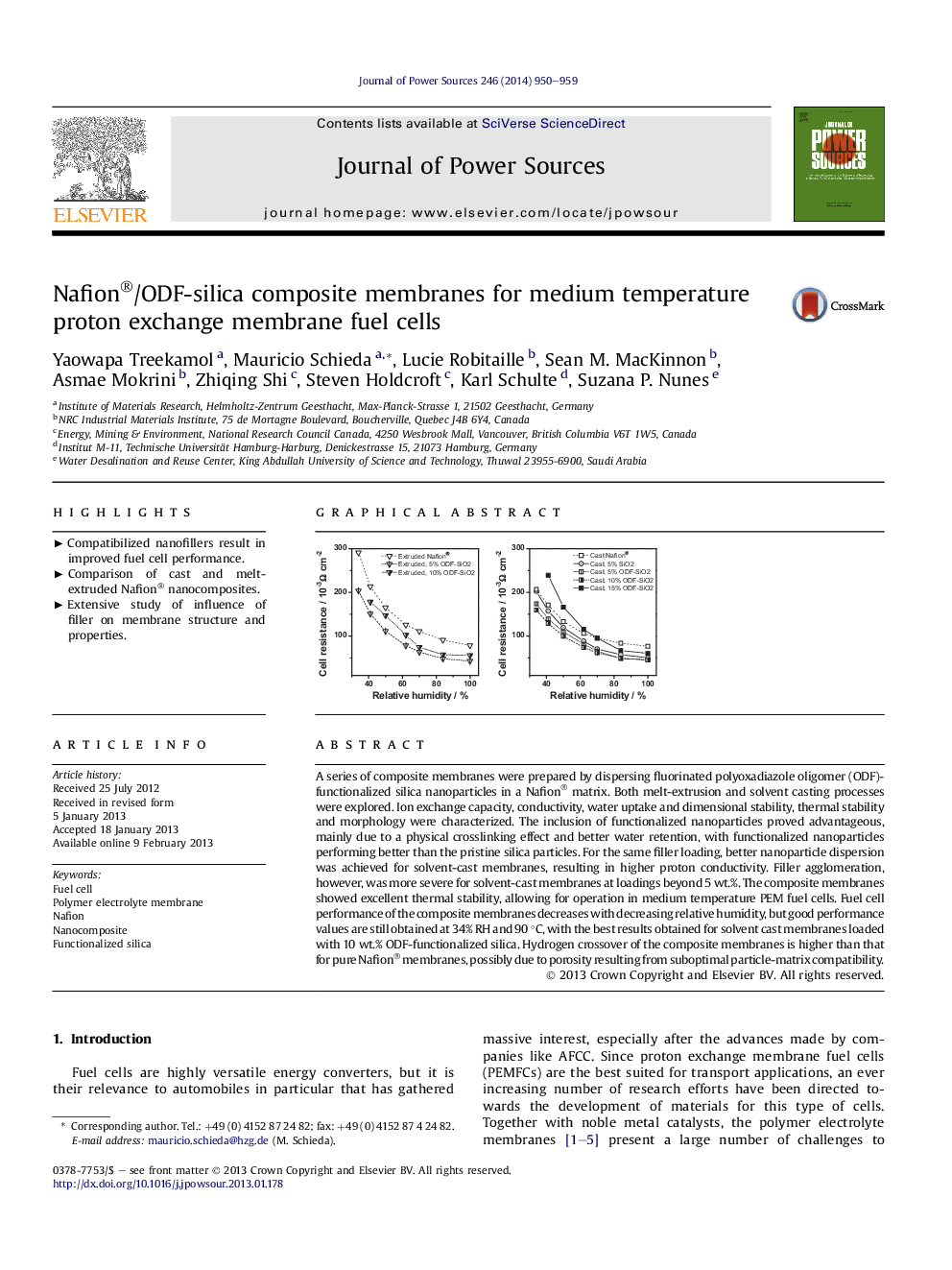

A series of composite membranes were prepared by dispersing fluorinated polyoxadiazole oligomer (ODF)-functionalized silica nanoparticles in a Nafion® matrix. Both melt-extrusion and solvent casting processes were explored. Ion exchange capacity, conductivity, water uptake and dimensional stability, thermal stability and morphology were characterized. The inclusion of functionalized nanoparticles proved advantageous, mainly due to a physical crosslinking effect and better water retention, with functionalized nanoparticles performing better than the pristine silica particles. For the same filler loading, better nanoparticle dispersion was achieved for solvent-cast membranes, resulting in higher proton conductivity. Filler agglomeration, however, was more severe for solvent-cast membranes at loadings beyond 5 wt.%. The composite membranes showed excellent thermal stability, allowing for operation in medium temperature PEM fuel cells. Fuel cell performance of the composite membranes decreases with decreasing relative humidity, but good performance values are still obtained at 34% RH and 90 °C, with the best results obtained for solvent cast membranes loaded with 10 wt.% ODF-functionalized silica. Hydrogen crossover of the composite membranes is higher than that for pure Nafion® membranes, possibly due to porosity resulting from suboptimal particle-matrix compatibility.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slideHighlights► Compatibilized nanofillers result in improved fuel cell performance. ► Comparison of cast and melt-extruded Nafion® nanocomposites. ► Extensive study of influence of filler on membrane structure and properties.