| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1285524 | Journal of Power Sources | 2016 | 8 Pages |

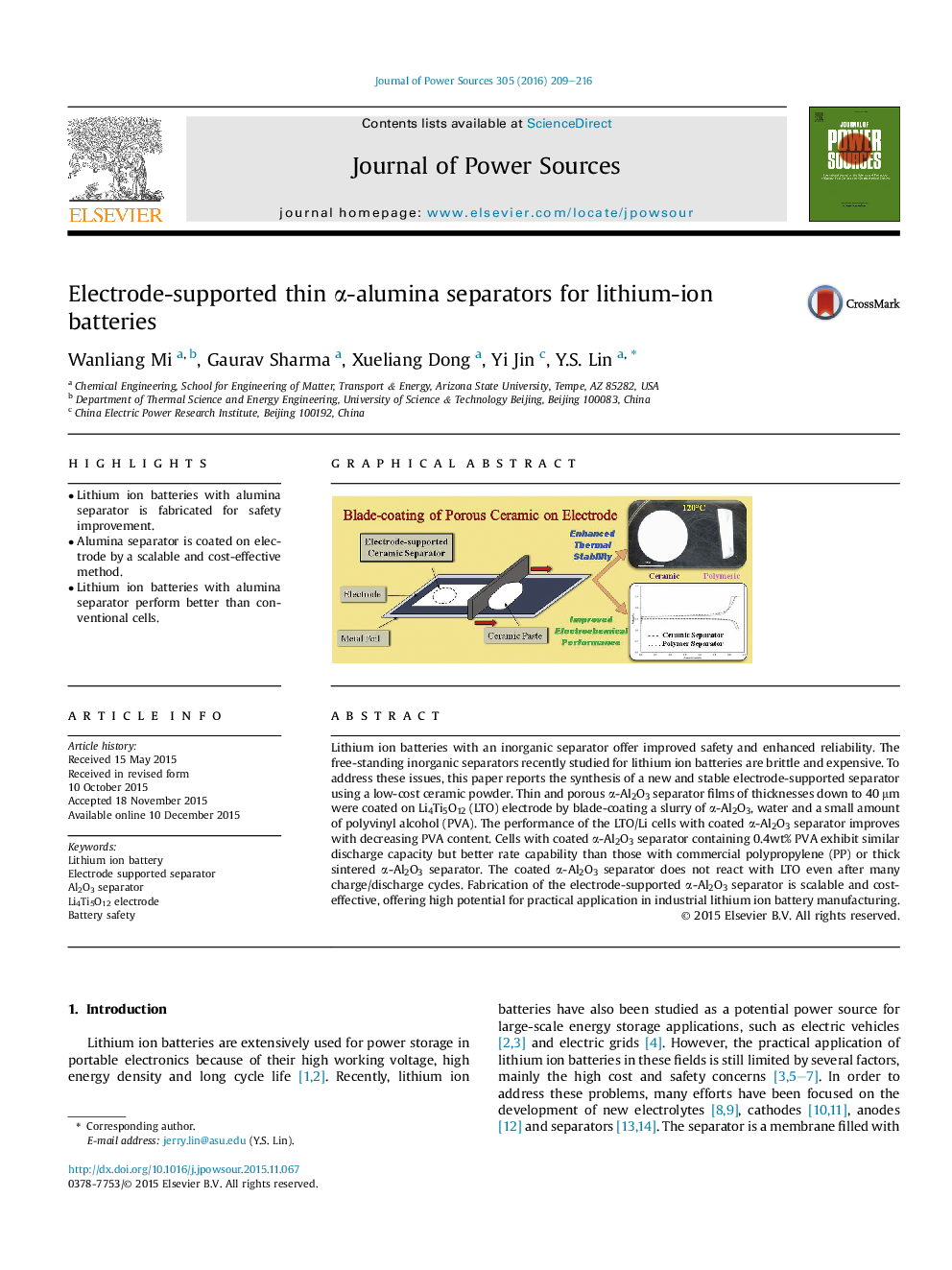

•Lithium ion batteries with alumina separator is fabricated for safety improvement.•Alumina separator is coated on electrode by a scalable and cost-effective method.•Lithium ion batteries with alumina separator perform better than conventional cells.

Lithium ion batteries with an inorganic separator offer improved safety and enhanced reliability. The free-standing inorganic separators recently studied for lithium ion batteries are brittle and expensive. To address these issues, this paper reports the synthesis of a new and stable electrode-supported separator using a low-cost ceramic powder. Thin and porous α-Al2O3 separator films of thicknesses down to 40 μm were coated on Li4Ti5O12 (LTO) electrode by blade-coating a slurry of α-Al2O3, water and a small amount of polyvinyl alcohol (PVA). The performance of the LTO/Li cells with coated α-Al2O3 separator improves with decreasing PVA content. Cells with coated α-Al2O3 separator containing 0.4wt% PVA exhibit similar discharge capacity but better rate capability than those with commercial polypropylene (PP) or thick sintered α-Al2O3 separator. The coated α-Al2O3 separator does not react with LTO even after many charge/discharge cycles. Fabrication of the electrode-supported α-Al2O3 separator is scalable and cost-effective, offering high potential for practical application in industrial lithium ion battery manufacturing.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide