| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1285728 | Journal of Power Sources | 2016 | 7 Pages |

•The NCF-BZCYYb possesses higher activity for CH4 steam reforming compared to Ni-YSZ.•The use of NCF-BZCYYb catalyst in the Ni-YSZ supported SOFC is studied.•NCF-BZCYYb coated single cell exhibits higher electrochemical performance in CH4.•NCF-BZCYYb coated single cell exhibits better durability and carbon resistance.

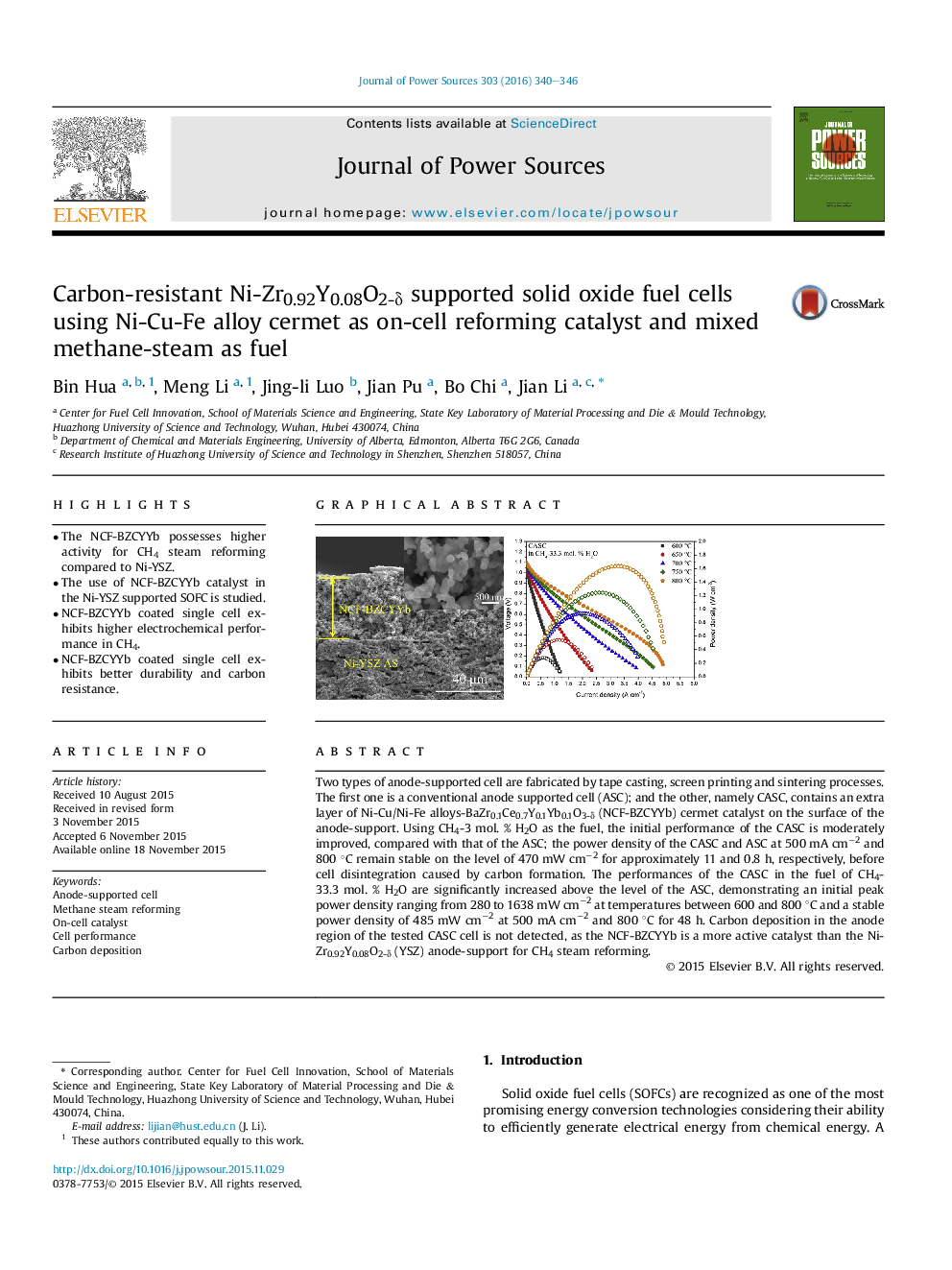

Two types of anode-supported cell are fabricated by tape casting, screen printing and sintering processes. The first one is a conventional anode supported cell (ASC); and the other, namely CASC, contains an extra layer of Ni-Cu/Ni-Fe alloys-BaZr0.1Ce0.7Y0.1Yb0.1O3-δ (NCF-BZCYYb) cermet catalyst on the surface of the anode-support. Using CH4-3 mol. % H2O as the fuel, the initial performance of the CASC is moderately improved, compared with that of the ASC; the power density of the CASC and ASC at 500 mA cm−2 and 800 °C remain stable on the level of 470 mW cm−2 for approximately 11 and 0.8 h, respectively, before cell disintegration caused by carbon formation. The performances of the CASC in the fuel of CH4-33.3 mol. % H2O are significantly increased above the level of the ASC, demonstrating an initial peak power density ranging from 280 to 1638 mW cm−2 at temperatures between 600 and 800 °C and a stable power density of 485 mW cm−2 at 500 mA cm−2 and 800 °C for 48 h. Carbon deposition in the anode region of the tested CASC cell is not detected, as the NCF-BZCYYb is a more active catalyst than the Ni-Zr0.92Y0.08O2-δ (YSZ) anode-support for CH4 steam reforming.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide