| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1285741 | Journal of Power Sources | 2016 | 7 Pages |

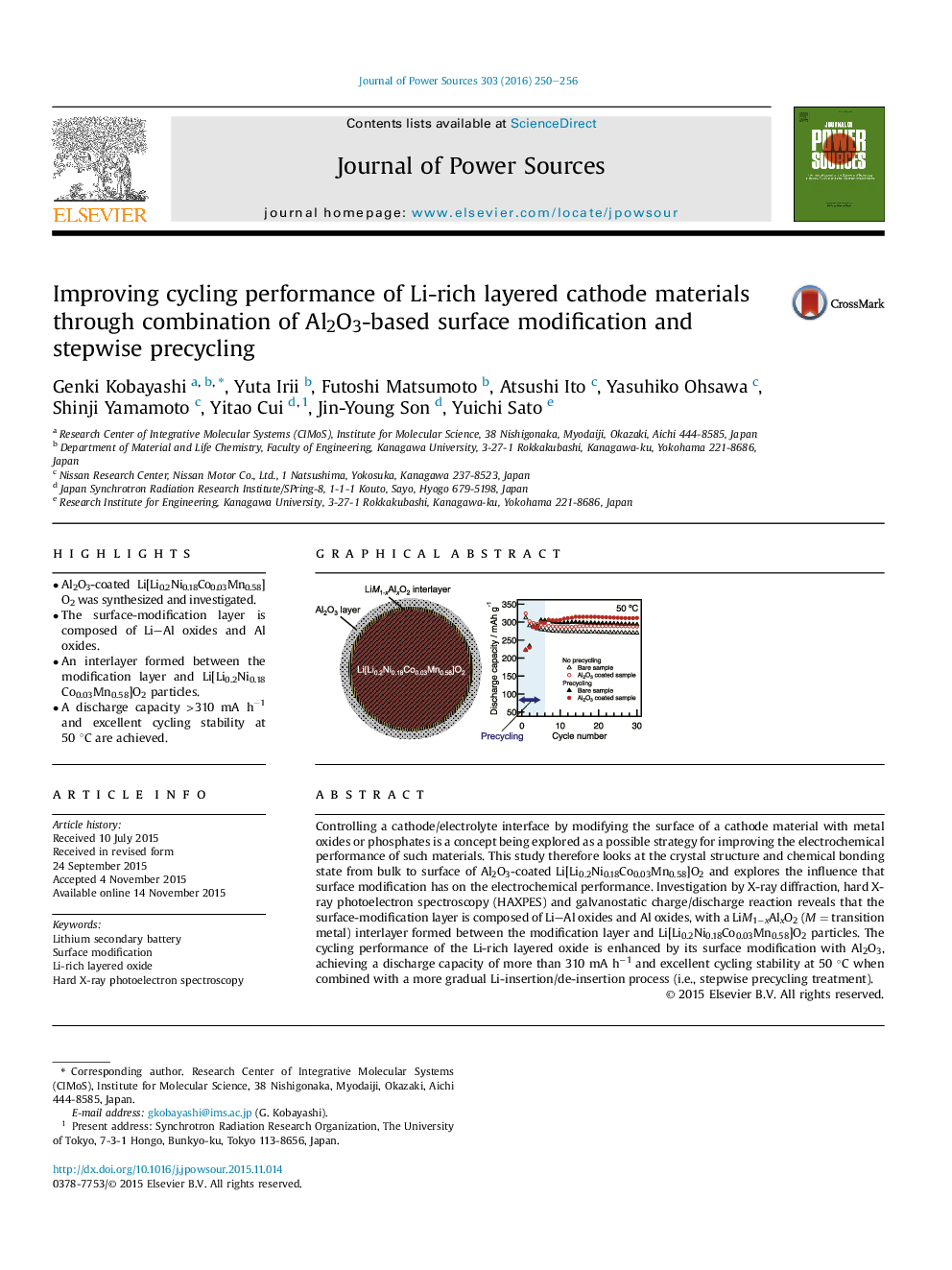

•Al2O3-coated Li[Li0.2Ni0.18Co0.03Mn0.58]O2 was synthesized and investigated.•The surface-modification layer is composed of Li–Al oxides and Al oxides.•An interlayer formed between the modification layer and Li[Li0.2Ni0.18Co0.03Mn0.58]O2 particles.•A discharge capacity >310 mA h−1 and excellent cycling stability at 50 °C are achieved.

Controlling a cathode/electrolyte interface by modifying the surface of a cathode material with metal oxides or phosphates is a concept being explored as a possible strategy for improving the electrochemical performance of such materials. This study therefore looks at the crystal structure and chemical bonding state from bulk to surface of Al2O3-coated Li[Li0.2Ni0.18Co0.03Mn0.58]O2 and explores the influence that surface modification has on the electrochemical performance. Investigation by X-ray diffraction, hard X-ray photoelectron spectroscopy (HAXPES) and galvanostatic charge/discharge reaction reveals that the surface-modification layer is composed of Li–Al oxides and Al oxides, with a LiM1−xAlxO2 (M = transition metal) interlayer formed between the modification layer and Li[Li0.2Ni0.18Co0.03Mn0.58]O2 particles. The cycling performance of the Li-rich layered oxide is enhanced by its surface modification with Al2O3, achieving a discharge capacity of more than 310 mA h−1 and excellent cycling stability at 50 °C when combined with a more gradual Li-insertion/de-insertion process (i.e., stepwise precycling treatment).

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide