| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1285792 | Journal of Power Sources | 2015 | 5 Pages |

•All solid state batteries were constructed with a mild and convenient approach.•Dense and highly conducting garnet electrolytes were used as supports of the cells.•Composite cathodes with highly conducting ionic and electronic networks were built.•The solid state batteries showed good performance at 60 °C.•Further elevated temperature like 100 °C led to greatly improved cell performance.

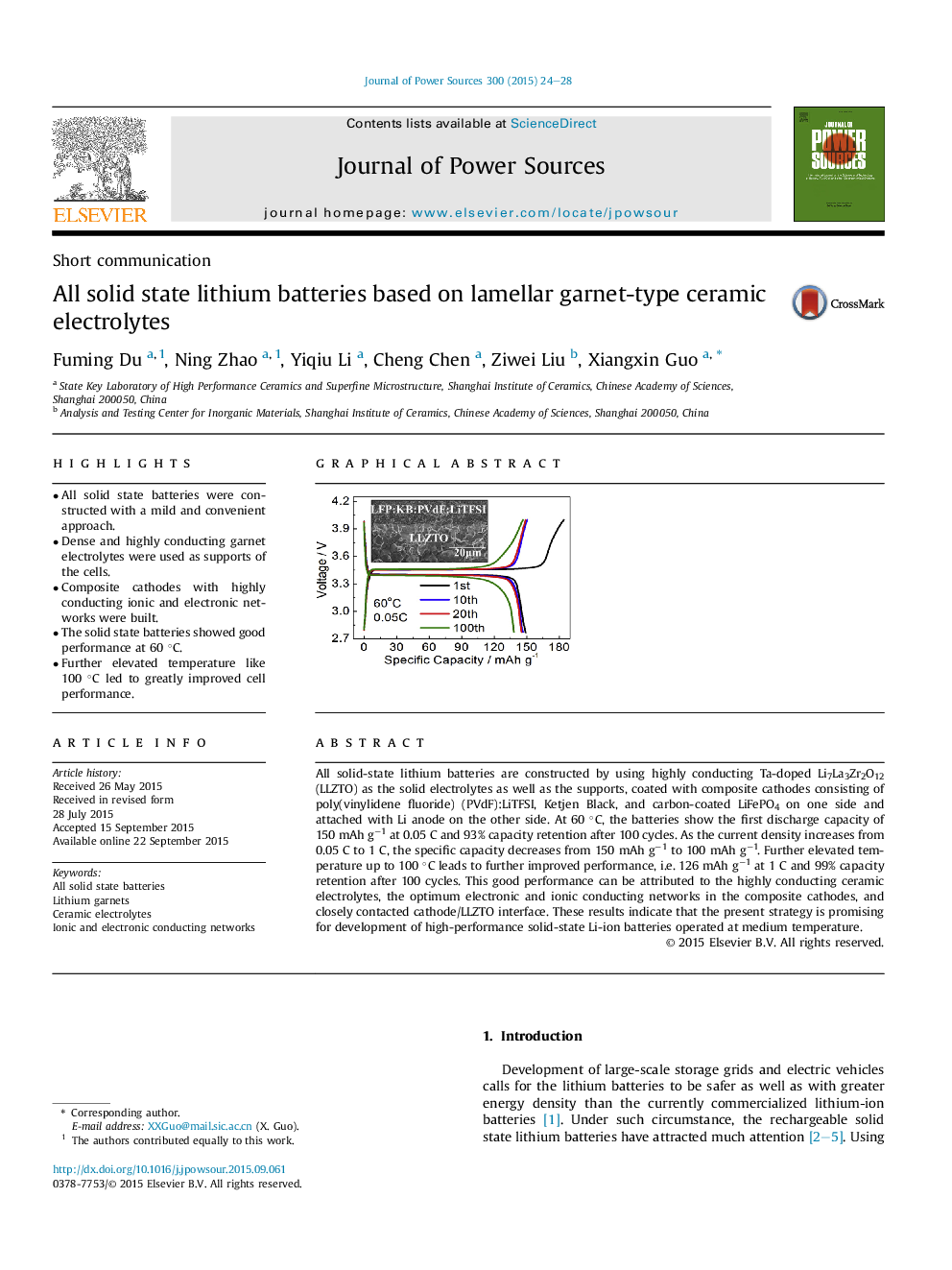

All solid-state lithium batteries are constructed by using highly conducting Ta-doped Li7La3Zr2O12 (LLZTO) as the solid electrolytes as well as the supports, coated with composite cathodes consisting of poly(vinylidene fluoride) (PVdF):LiTFSI, Ketjen Black, and carbon-coated LiFePO4 on one side and attached with Li anode on the other side. At 60 °C, the batteries show the first discharge capacity of 150 mAh g−1 at 0.05 C and 93% capacity retention after 100 cycles. As the current density increases from 0.05 C to 1 C, the specific capacity decreases from 150 mAh g−1 to 100 mAh g−1. Further elevated temperature up to 100 °C leads to further improved performance, i.e. 126 mAh g−1 at 1 C and 99% capacity retention after 100 cycles. This good performance can be attributed to the highly conducting ceramic electrolytes, the optimum electronic and ionic conducting networks in the composite cathodes, and closely contacted cathode/LLZTO interface. These results indicate that the present strategy is promising for development of high-performance solid-state Li-ion batteries operated at medium temperature.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide