| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1286627 | Journal of Power Sources | 2014 | 6 Pages |

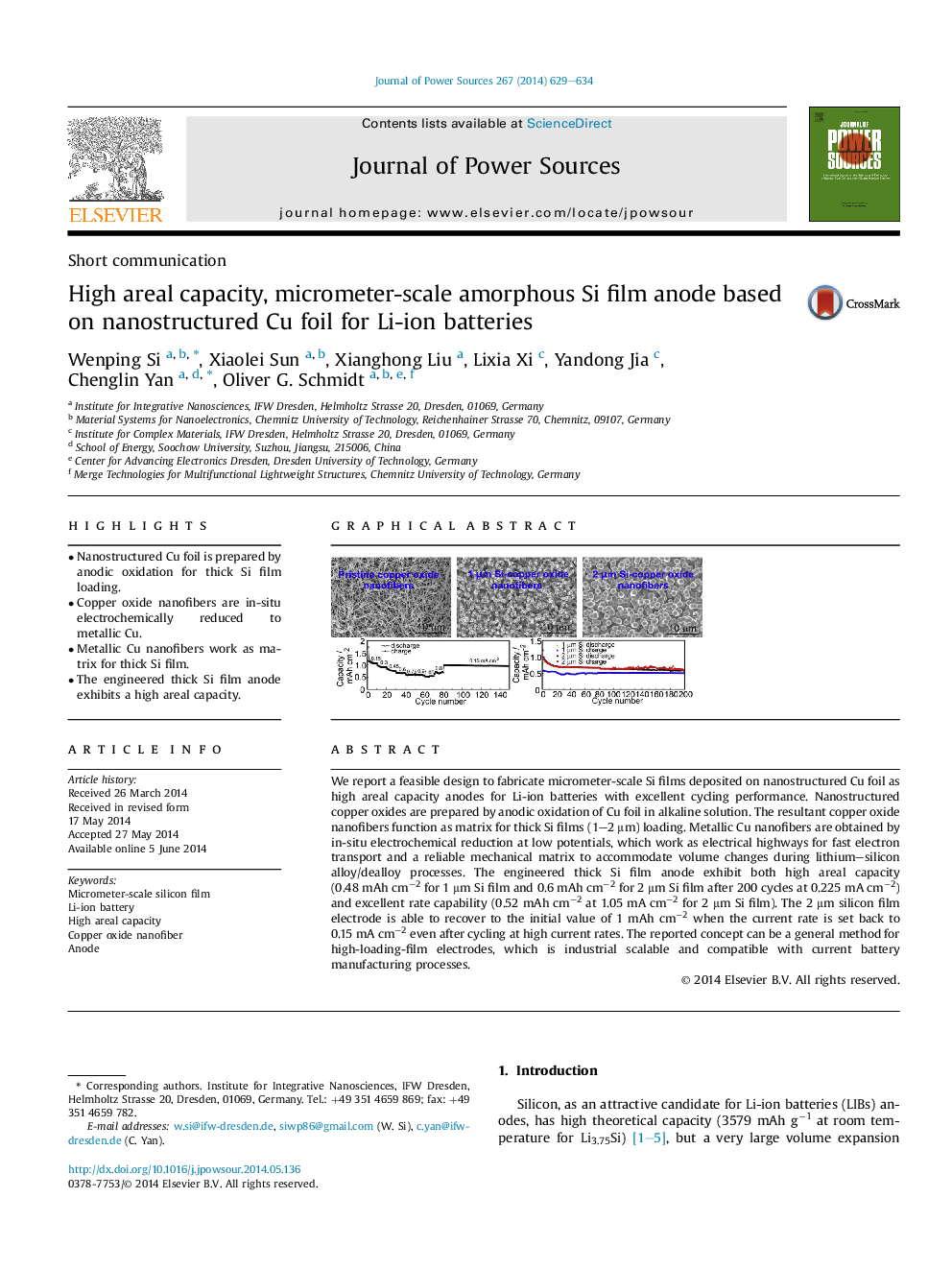

•Nanostructured Cu foil is prepared by anodic oxidation for thick Si film loading.•Copper oxide nanofibers are in-situ electrochemically reduced to metallic Cu.•Metallic Cu nanofibers work as matrix for thick Si film.•The engineered thick Si film anode exhibits a high areal capacity.

We report a feasible design to fabricate micrometer-scale Si films deposited on nanostructured Cu foil as high areal capacity anodes for Li-ion batteries with excellent cycling performance. Nanostructured copper oxides are prepared by anodic oxidation of Cu foil in alkaline solution. The resultant copper oxide nanofibers function as matrix for thick Si films (1–2 μm) loading. Metallic Cu nanofibers are obtained by in-situ electrochemical reduction at low potentials, which work as electrical highways for fast electron transport and a reliable mechanical matrix to accommodate volume changes during lithium–silicon alloy/dealloy processes. The engineered thick Si film anode exhibit both high areal capacity (0.48 mAh cm−2 for 1 μm Si film and 0.6 mAh cm−2 for 2 μm Si film after 200 cycles at 0.225 mA cm−2) and excellent rate capability (0.52 mAh cm−2 at 1.05 mA cm−2 for 2 μm Si film). The 2 μm silicon film electrode is able to recover to the initial value of 1 mAh cm−2 when the current rate is set back to 0.15 mA cm−2 even after cycling at high current rates. The reported concept can be a general method for high-loading-film electrodes, which is industrial scalable and compatible with current battery manufacturing processes.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide