| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1291996 | Journal of Power Sources | 2016 | 8 Pages |

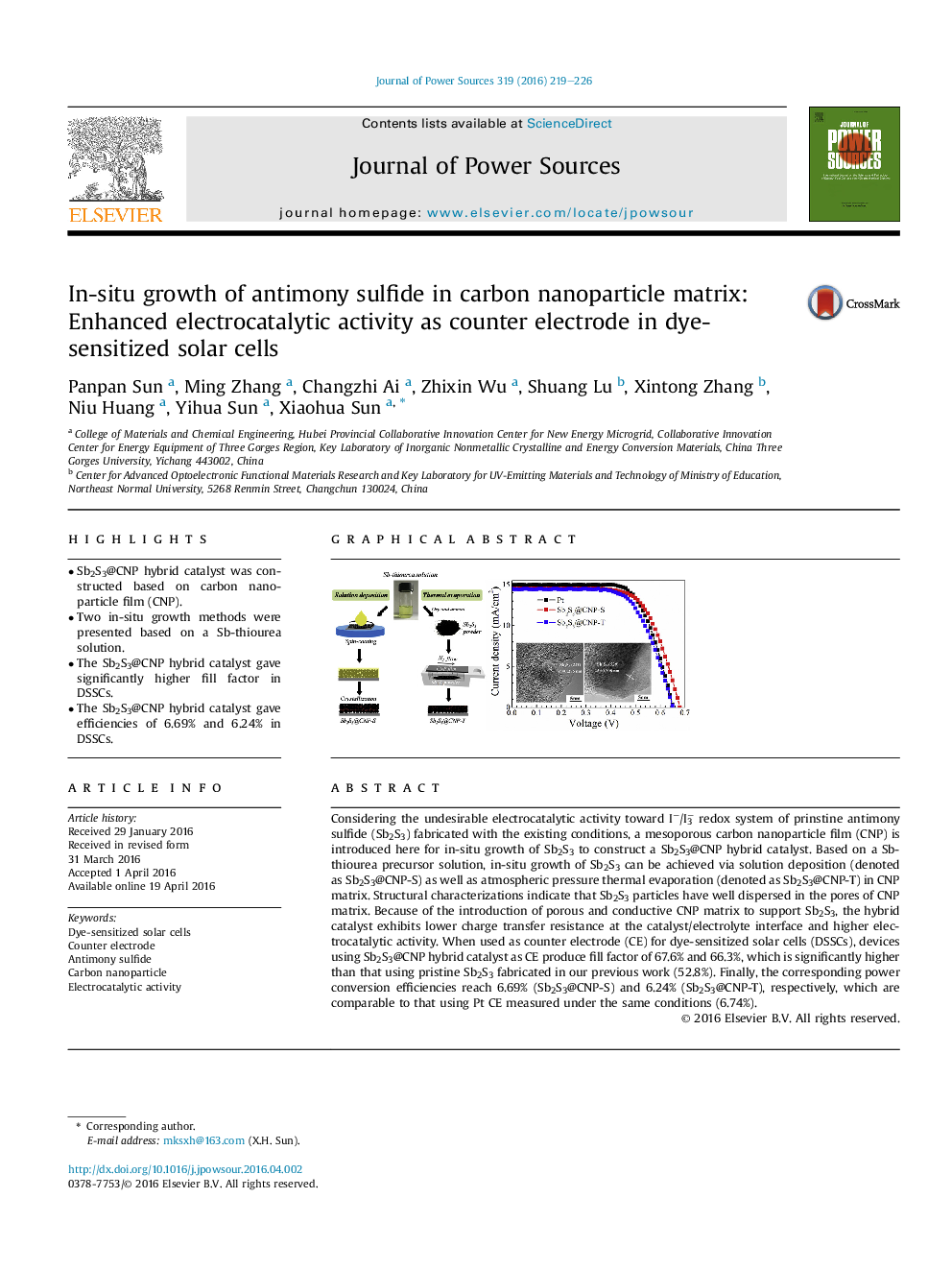

•Sb2S3@CNP hybrid catalyst was constructed based on carbon nanoparticle film (CNP).•Two in-situ growth methods were presented based on a Sb-thiourea solution.•The Sb2S3@CNP hybrid catalyst gave significantly higher fill factor in DSSCs.•The Sb2S3@CNP hybrid catalyst gave efficiencies of 6.69% and 6.24% in DSSCs.

Considering the undesirable electrocatalytic activity toward I−/I3− redox system of prinstine antimony sulfide (Sb2S3) fabricated with the existing conditions, a mesoporous carbon nanoparticle film (CNP) is introduced here for in-situ growth of Sb2S3 to construct a Sb2S3@CNP hybrid catalyst. Based on a Sb-thiourea precursor solution, in-situ growth of Sb2S3 can be achieved via solution deposition (denoted as Sb2S3@CNP-S) as well as atmospheric pressure thermal evaporation (denoted as Sb2S3@CNP-T) in CNP matrix. Structural characterizations indicate that Sb2S3 particles have well dispersed in the pores of CNP matrix. Because of the introduction of porous and conductive CNP matrix to support Sb2S3, the hybrid catalyst exhibits lower charge transfer resistance at the catalyst/electrolyte interface and higher electrocatalytic activity. When used as counter electrode (CE) for dye-sensitized solar cells (DSSCs), devices using Sb2S3@CNP hybrid catalyst as CE produce fill factor of 67.6% and 66.3%, which is significantly higher than that using pristine Sb2S3 fabricated in our previous work (52.8%). Finally, the corresponding power conversion efficiencies reach 6.69% (Sb2S3@CNP-S) and 6.24% (Sb2S3@CNP-T), respectively, which are comparable to that using Pt CE measured under the same conditions (6.74%).

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide