| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1292367 | Journal of Power Sources | 2016 | 8 Pages |

•Li2S@C composite was prepared by ball milling combined with carbon coating method.•Li2S@C composite showed superior cycling properties and rate capability.•The mechanism for improved electrochemical properties of Li2S was discussed.

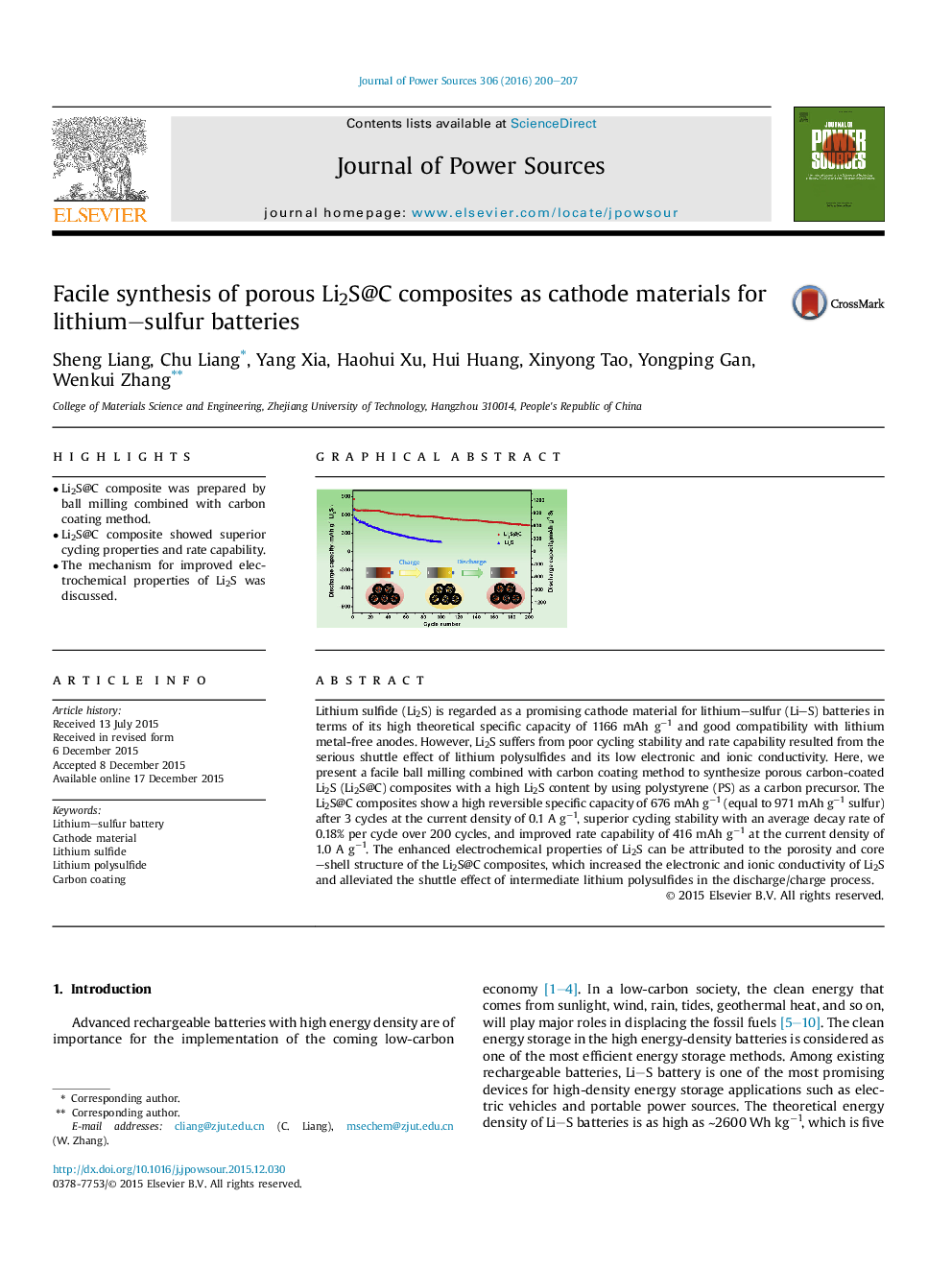

Lithium sulfide (Li2S) is regarded as a promising cathode material for lithium–sulfur (Li–S) batteries in terms of its high theoretical specific capacity of 1166 mAh g−1 and good compatibility with lithium metal-free anodes. However, Li2S suffers from poor cycling stability and rate capability resulted from the serious shuttle effect of lithium polysulfides and its low electronic and ionic conductivity. Here, we present a facile ball milling combined with carbon coating method to synthesize porous carbon-coated Li2S (Li2S@C) composites with a high Li2S content by using polystyrene (PS) as a carbon precursor. The Li2S@C composites show a high reversible specific capacity of 676 mAh g−1 (equal to 971 mAh g−1 sulfur) after 3 cycles at the current density of 0.1 A g−1, superior cycling stability with an average decay rate of 0.18% per cycle over 200 cycles, and improved rate capability of 416 mAh g−1 at the current density of 1.0 A g−1. The enhanced electrochemical properties of Li2S can be attributed to the porosity and core–shell structure of the Li2S@C composites, which increased the electronic and ionic conductivity of Li2S and alleviated the shuttle effect of intermediate lithium polysulfides in the discharge/charge process.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide