| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1292404 | Journal of Power Sources | 2016 | 6 Pages |

•We demonstrate a rapid and facile novel solvent-free direct coating process.•The hot-pressing time had an effect on the electrode morphologies and performance.•The DS-LTO-60 electrode showed excellent electrical conductivity and Li+ storage.•Dry-spraying process has significant potential as an important industrial technique.

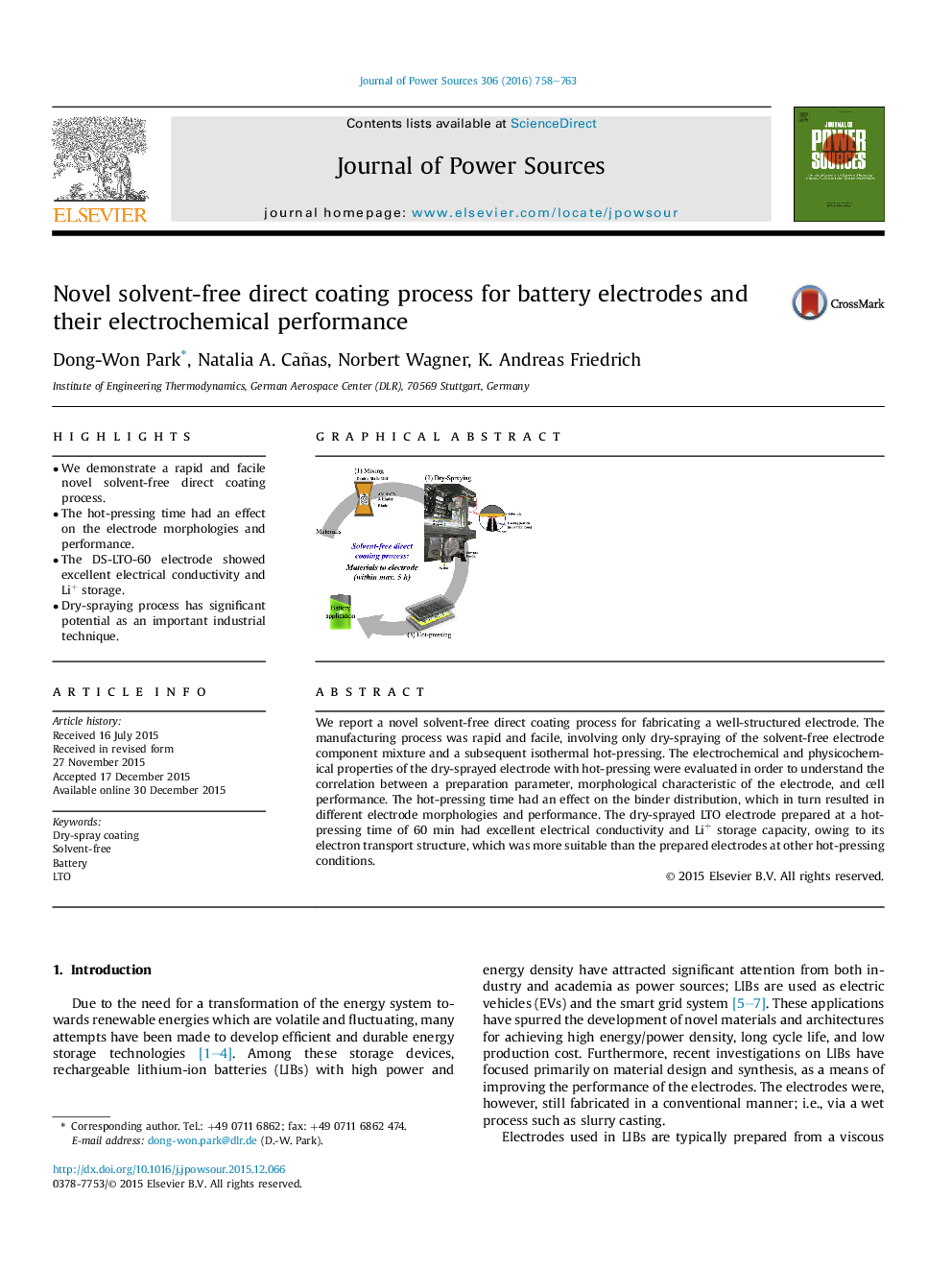

We report a novel solvent-free direct coating process for fabricating a well-structured electrode. The manufacturing process was rapid and facile, involving only dry-spraying of the solvent-free electrode component mixture and a subsequent isothermal hot-pressing. The electrochemical and physicochemical properties of the dry-sprayed electrode with hot-pressing were evaluated in order to understand the correlation between a preparation parameter, morphological characteristic of the electrode, and cell performance. The hot-pressing time had an effect on the binder distribution, which in turn resulted in different electrode morphologies and performance. The dry-sprayed LTO electrode prepared at a hot-pressing time of 60 min had excellent electrical conductivity and Li+ storage capacity, owing to its electron transport structure, which was more suitable than the prepared electrodes at other hot-pressing conditions.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide