| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 1292760 | Journal of Power Sources | 2015 | 7 Pages |

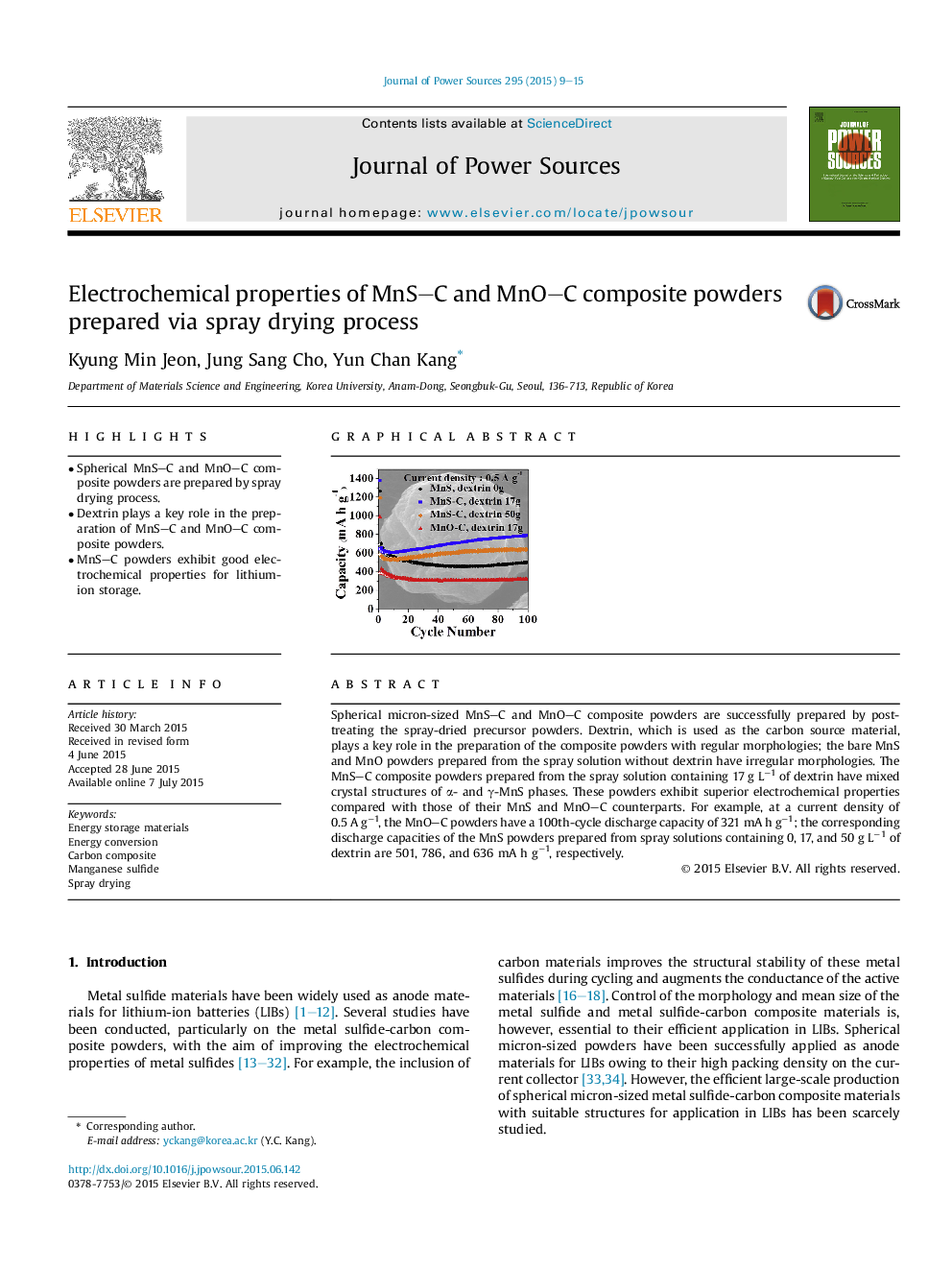

•Spherical MnS–C and MnO–C composite powders are prepared by spray drying process.•Dextrin plays a key role in the preparation of MnS–C and MnO–C composite powders.•MnS–C powders exhibit good electrochemical properties for lithium-ion storage.

Spherical micron-sized MnS–C and MnO–C composite powders are successfully prepared by post-treating the spray-dried precursor powders. Dextrin, which is used as the carbon source material, plays a key role in the preparation of the composite powders with regular morphologies; the bare MnS and MnO powders prepared from the spray solution without dextrin have irregular morphologies. The MnS–C composite powders prepared from the spray solution containing 17 g L−1 of dextrin have mixed crystal structures of α- and γ-MnS phases. These powders exhibit superior electrochemical properties compared with those of their MnS and MnO–C counterparts. For example, at a current density of 0.5 A g−1, the MnO–C powders have a 100th-cycle discharge capacity of 321 mA h g−1; the corresponding discharge capacities of the MnS powders prepared from spray solutions containing 0, 17, and 50 g L−1 of dextrin are 501, 786, and 636 mA h g−1, respectively.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide