| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 145305 | Chemical Engineering Journal | 2016 | 9 Pages |

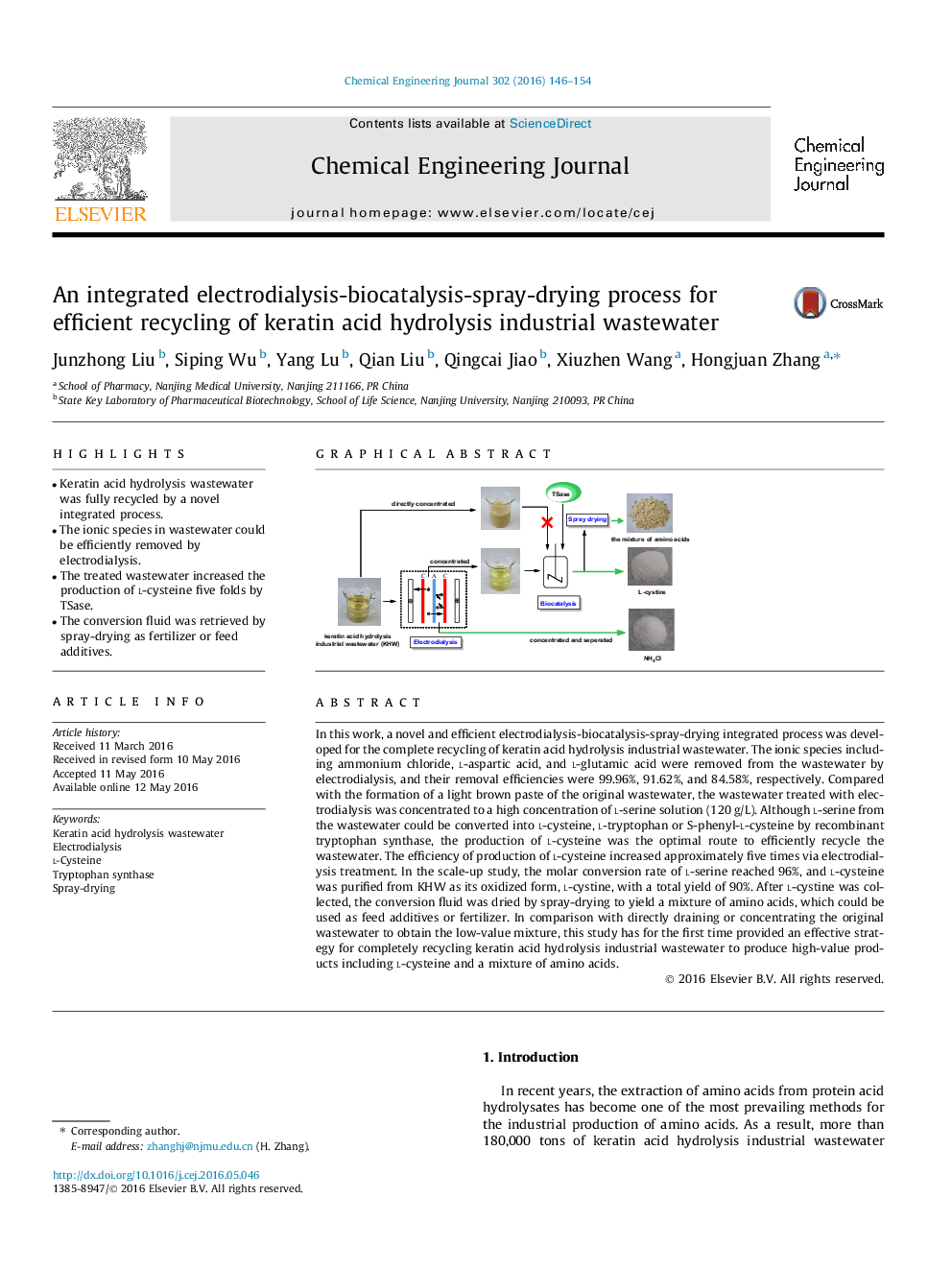

•Keratin acid hydrolysis wastewater was fully recycled by a novel integrated process.•The ionic species in wastewater could be efficiently removed by electrodialysis.•The treated wastewater increased the production of l-cysteine five folds by TSase.•The conversion fluid was retrieved by spray-drying as fertilizer or feed additives.

In this work, a novel and efficient electrodialysis-biocatalysis-spray-drying integrated process was developed for the complete recycling of keratin acid hydrolysis industrial wastewater. The ionic species including ammonium chloride, l-aspartic acid, and l-glutamic acid were removed from the wastewater by electrodialysis, and their removal efficiencies were 99.96%, 91.62%, and 84.58%, respectively. Compared with the formation of a light brown paste of the original wastewater, the wastewater treated with electrodialysis was concentrated to a high concentration of l-serine solution (120 g/L). Although l-serine from the wastewater could be converted into l-cysteine, l-tryptophan or S-phenyl-l-cysteine by recombinant tryptophan synthase, the production of l-cysteine was the optimal route to efficiently recycle the wastewater. The efficiency of production of l-cysteine increased approximately five times via electrodialysis treatment. In the scale-up study, the molar conversion rate of l-serine reached 96%, and l-cysteine was purified from KHW as its oxidized form, l-cystine, with a total yield of 90%. After l-cystine was collected, the conversion fluid was dried by spray-drying to yield a mixture of amino acids, which could be used as feed additives or fertilizer. In comparison with directly draining or concentrating the original wastewater to obtain the low-value mixture, this study has for the first time provided an effective strategy for completely recycling keratin acid hydrolysis industrial wastewater to produce high-value products including l-cysteine and a mixture of amino acids.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide