| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 145394 | Chemical Engineering Journal | 2016 | 9 Pages |

•Polyvinyltetrazole (PVT)-co-PAN based ultrafiltration membranes were fabricated.•PVT segment played a significant role for copper adsorption.•The binding capacity of PVT–PAN membranes for Cu(II) ions exceeded 130 mg g−1.•Copper loaded membranes could be regenerated with 0.25 mM EDTA solution.

Novel adsorptive ultrafiltration membranes were manufactured from synthesized polyvinyltetrazole-co-polyacrylonitrile (PVT-co-PAN) by nonsolvent induced phase separation (NIPS). PVT-co-PAN with various degree of functionalization (DF) was synthesized via a [3 + 2] cycloaddition reaction at 60 °C using a commercial PAN. PVT-co-PAN with varied DF was then explored to prepare adsorptive membranes. The membranes were characterized by surface zeta potential and static water contact angle measurements, scanning electron microscopy as well as atomic force microscopy (AFM) techniques. It was shown that PVT segments contributed to alter the pore size, charge and hydrophilic behavior of the membranes. The membranes became more negatively charged and hydrophilic after addition of PVT segments. The PVT segments in the membranes served as the major binding sites for adsorption of Cu(II) ions from aqueous solution. The maximum adsorption of Cu(II) ions by the membranes in static condition and in a continuous ultrafiltration of 10 ppm solution was attained at pH = 5. The adsorption data suggest that the Freundlich isotherm model describes well Cu(II) ions adsorption on the membranes from aqueous solution. The adsorption capacity obtained from the Freundlich isotherm model was 44.3 mg g−1; this value is higher than other membrane adsorption data reported in the literature. Overall, the membranes fabricated from PVT-co-PAN are attractive for efficient removal of heavy metal ions under the optimized conditions.

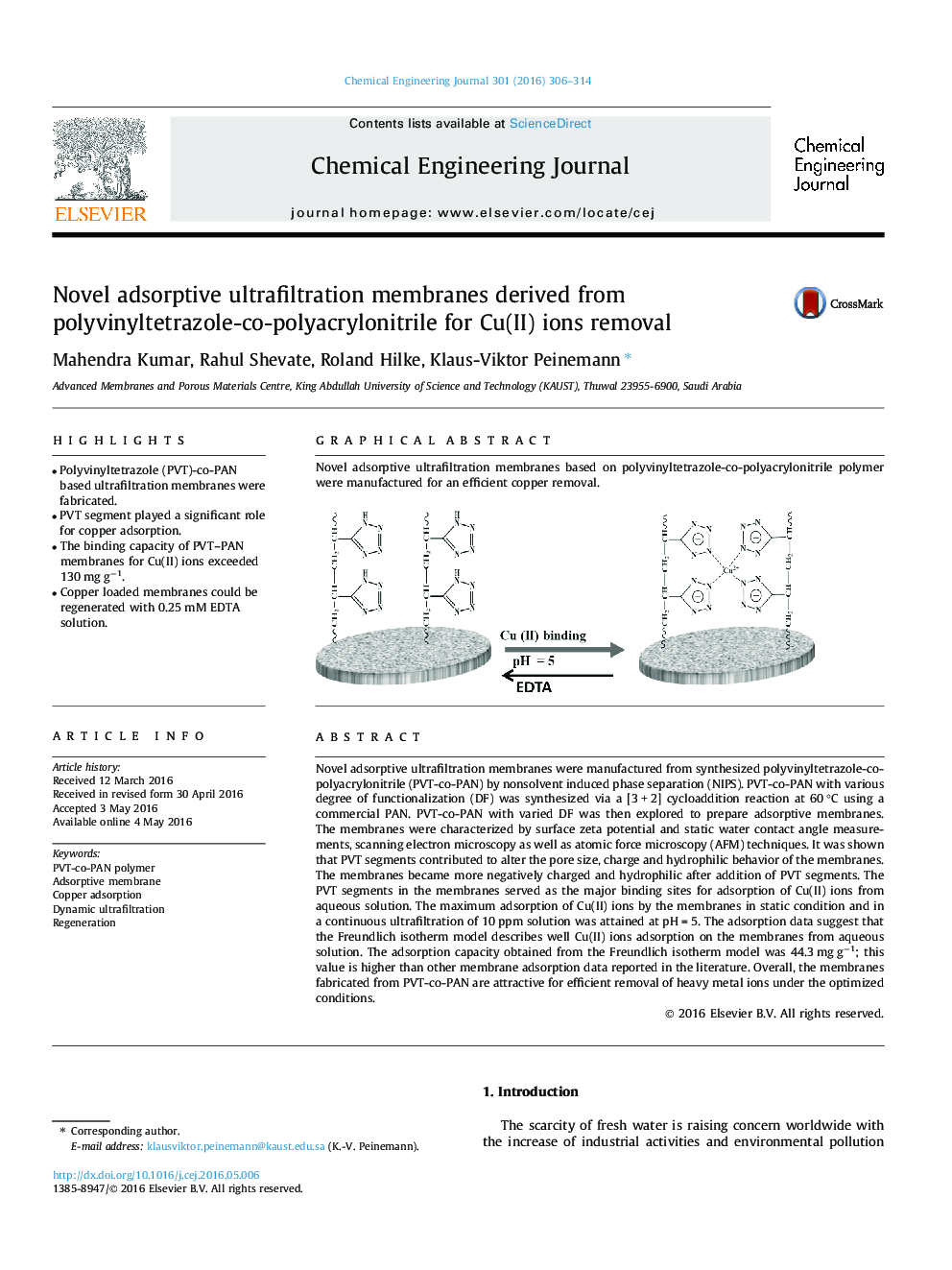

Graphical abstractNovel adsorptive ultrafiltration membranes based on polyvinyltetrazole-co-polyacrylonitrile polymer were manufactured for an efficient copper removal.Figure optionsDownload full-size imageDownload as PowerPoint slide