| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 145513 | Chemical Engineering Journal | 2016 | 9 Pages |

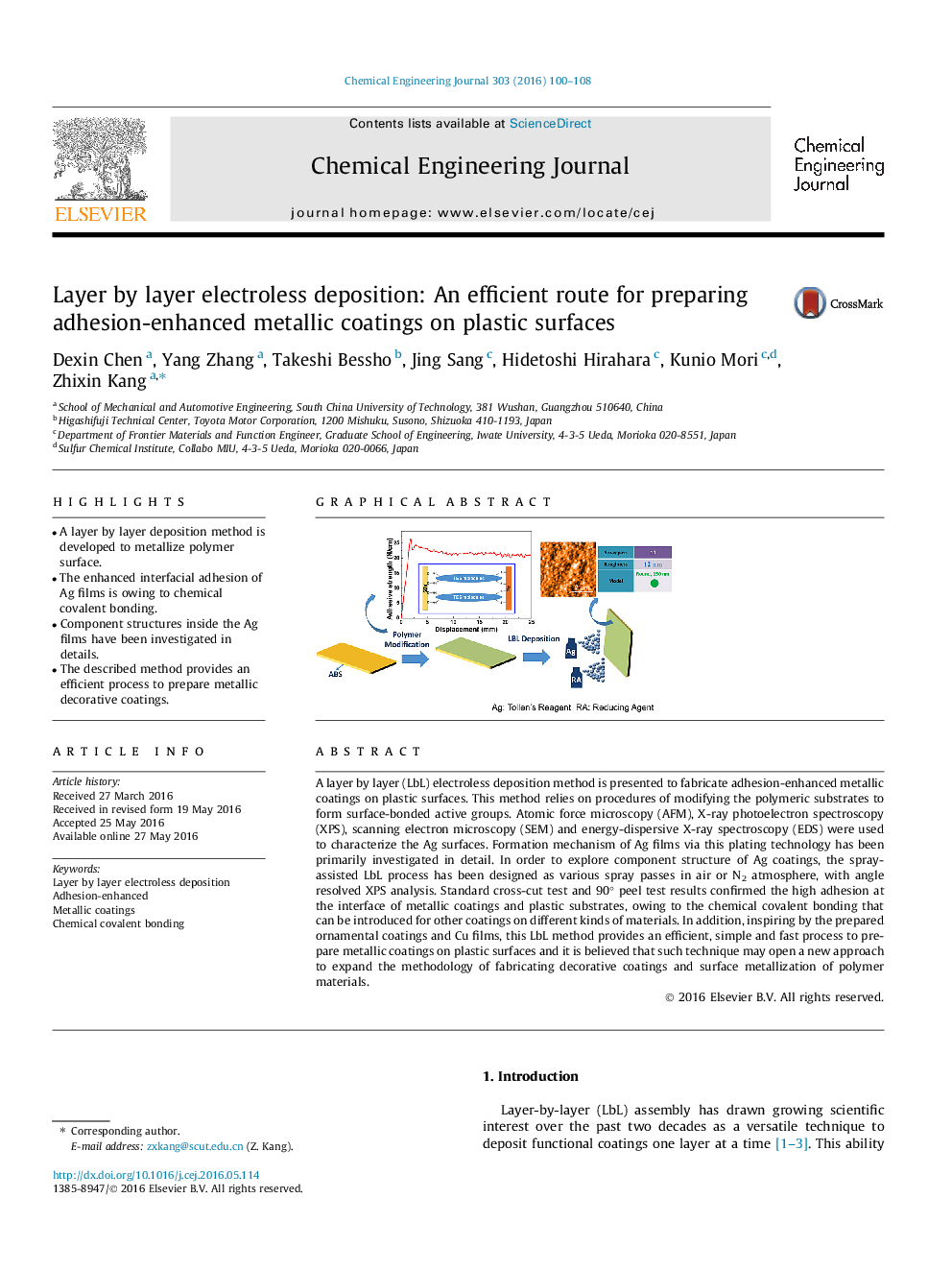

•A layer by layer deposition method is developed to metallize polymer surface.•The enhanced interfacial adhesion of Ag films is owing to chemical covalent bonding.•Component structures inside the Ag films have been investigated in details.•The described method provides an efficient process to prepare metallic decorative coatings.

A layer by layer (LbL) electroless deposition method is presented to fabricate adhesion-enhanced metallic coatings on plastic surfaces. This method relies on procedures of modifying the polymeric substrates to form surface-bonded active groups. Atomic force microscopy (AFM), X-ray photoelectron spectroscopy (XPS), scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) were used to characterize the Ag surfaces. Formation mechanism of Ag films via this plating technology has been primarily investigated in detail. In order to explore component structure of Ag coatings, the spray-assisted LbL process has been designed as various spray passes in air or N2 atmosphere, with angle resolved XPS analysis. Standard cross-cut test and 90° peel test results confirmed the high adhesion at the interface of metallic coatings and plastic substrates, owing to the chemical covalent bonding that can be introduced for other coatings on different kinds of materials. In addition, inspiring by the prepared ornamental coatings and Cu films, this LbL method provides an efficient, simple and fast process to prepare metallic coatings on plastic surfaces and it is believed that such technique may open a new approach to expand the methodology of fabricating decorative coatings and surface metallization of polymer materials.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide