| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 145598 | Chemical Engineering Journal | 2016 | 7 Pages |

•Magnetic rubber was made from Ba-ferrite (BaM) and waste rubber powders (WRPs).•Surface modification of BaM and activation of WRPs were simultaneously achieved.•Microwave devulcanization of WRPs was enhanced after adding BaM powders.•A novel route was designed for fabricating low cost flexible rubber magnets.

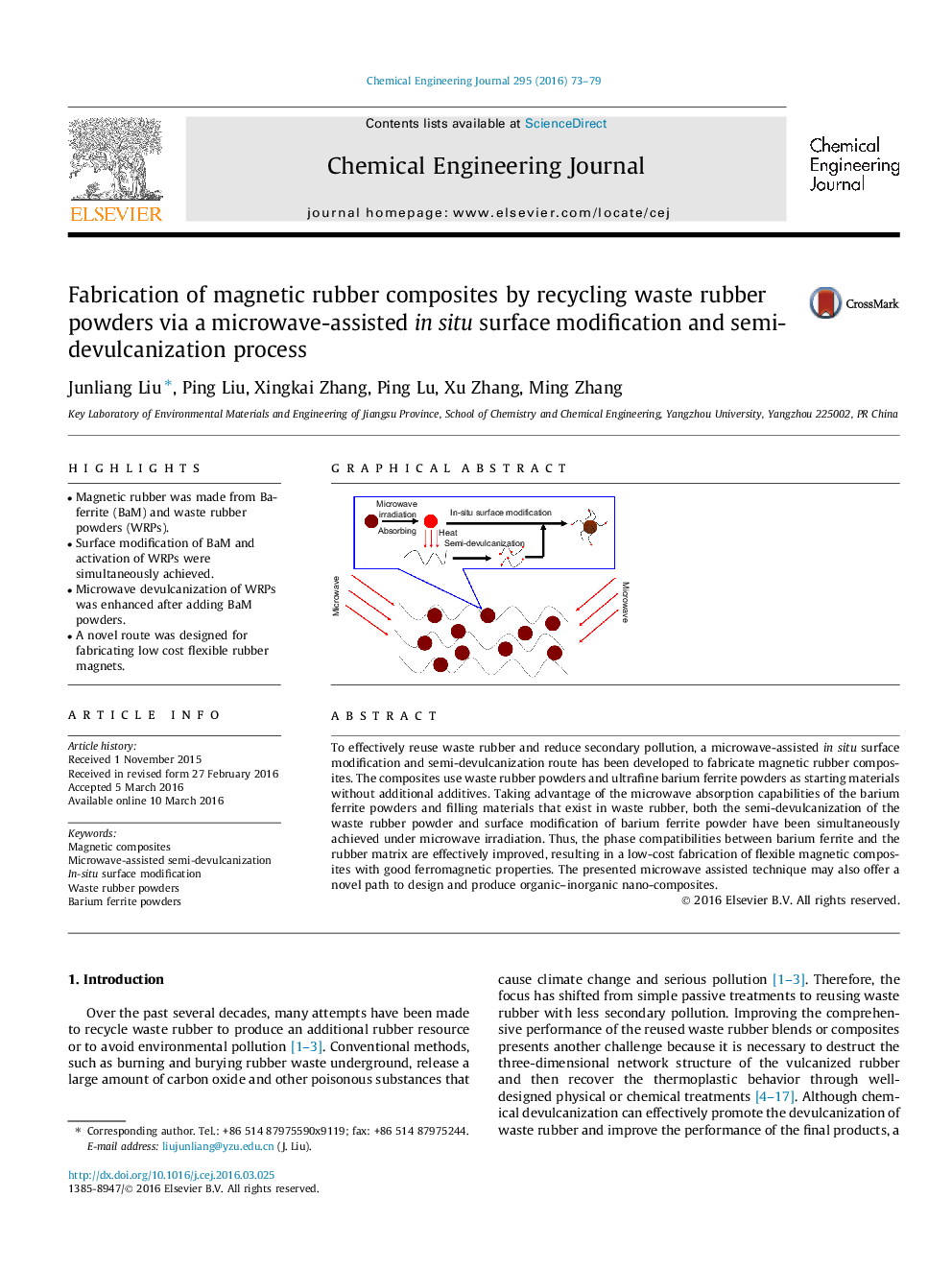

To effectively reuse waste rubber and reduce secondary pollution, a microwave-assisted in situ surface modification and semi-devulcanization route has been developed to fabricate magnetic rubber composites. The composites use waste rubber powders and ultrafine barium ferrite powders as starting materials without additional additives. Taking advantage of the microwave absorption capabilities of the barium ferrite powders and filling materials that exist in waste rubber, both the semi-devulcanization of the waste rubber powder and surface modification of barium ferrite powder have been simultaneously achieved under microwave irradiation. Thus, the phase compatibilities between barium ferrite and the rubber matrix are effectively improved, resulting in a low-cost fabrication of flexible magnetic composites with good ferromagnetic properties. The presented microwave assisted technique may also offer a novel path to design and produce organic–inorganic nano-composites.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide