| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 145670 | Chemical Engineering Journal | 2016 | 14 Pages |

•Membrane became more hydrophilic and porous with addition of GO.•Above 90% rejection of Cr, Cd, Pb and Cu was effected by MMM.•Membrane performed better in basic pH, low pressure and flow rate.•In-situ membrane regeneration was possible by acid treatment.

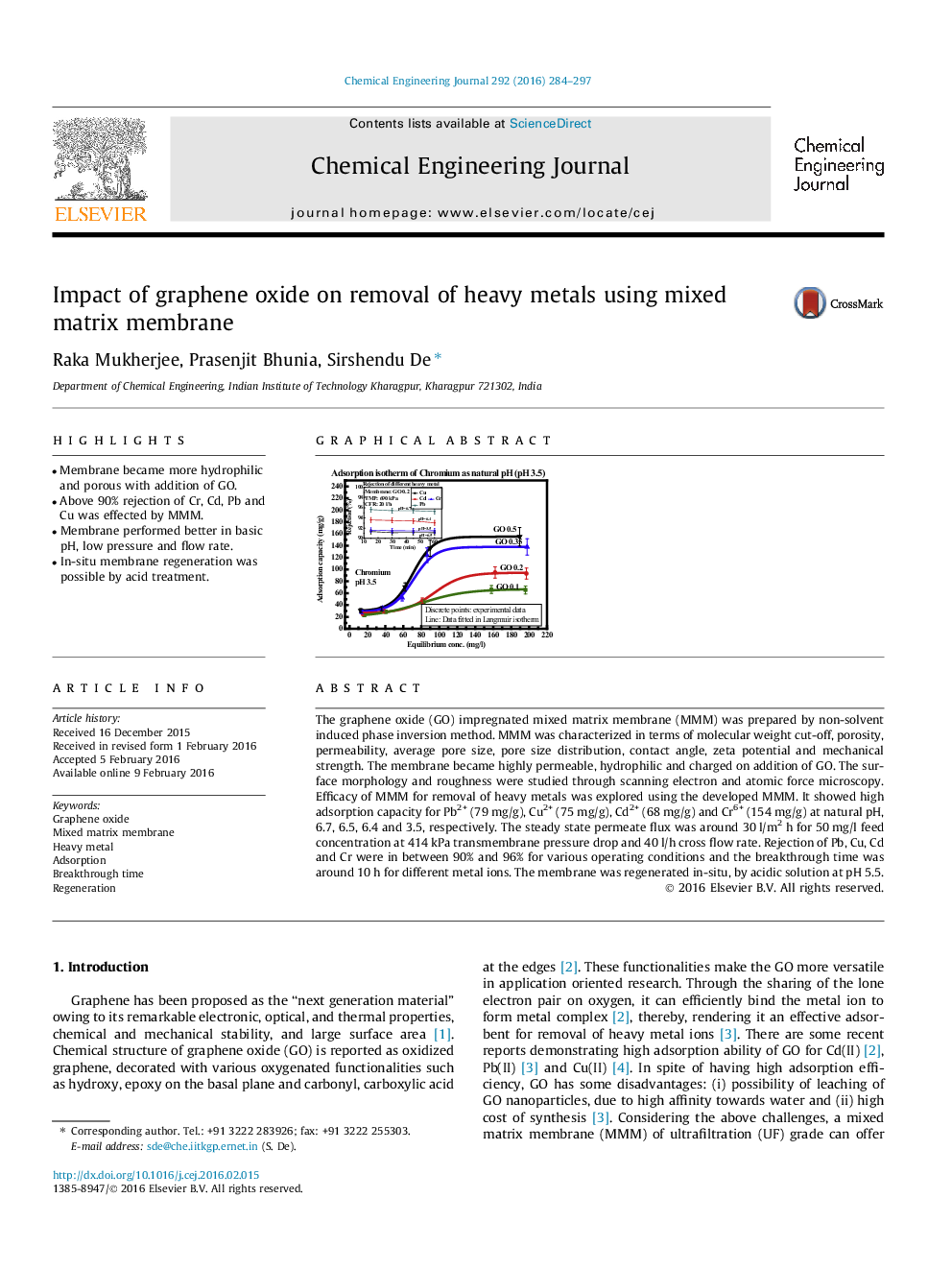

The graphene oxide (GO) impregnated mixed matrix membrane (MMM) was prepared by non-solvent induced phase inversion method. MMM was characterized in terms of molecular weight cut-off, porosity, permeability, average pore size, pore size distribution, contact angle, zeta potential and mechanical strength. The membrane became highly permeable, hydrophilic and charged on addition of GO. The surface morphology and roughness were studied through scanning electron and atomic force microscopy. Efficacy of MMM for removal of heavy metals was explored using the developed MMM. It showed high adsorption capacity for Pb2+ (79 mg/g), Cu2+ (75 mg/g), Cd2+ (68 mg/g) and Cr6+ (154 mg/g) at natural pH, 6.7, 6.5, 6.4 and 3.5, respectively. The steady state permeate flux was around 30 l/m2 h for 50 mg/l feed concentration at 414 kPa transmembrane pressure drop and 40 l/h cross flow rate. Rejection of Pb, Cu, Cd and Cr were in between 90% and 96% for various operating conditions and the breakthrough time was around 10 h for different metal ions. The membrane was regenerated in-situ, by acidic solution at pH 5.5.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide