| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 145726 | Chemical Engineering Journal | 2016 | 11 Pages |

•A model describing desulfurization of biogas in a biotrickling filter was developed.•Calibration at 5 H2S loading rates allowed estimating 5 model parameters.•Model validation was performed with dynamic elemental sulfur and sulfate profiles.•H2S removal was influenced by G–L mass transfer and by biological degradation.•G–L oxygen transfer is crucial to avoid sulfur accumulation in the packed bed.

A dynamic model describing physical–chemical and biological processes for the removal of high loads of H2S from biogas streams in biotrickling filters (BTFs) was developed, calibrated and validated for a wide range of experimental conditions in a lab-scale BTF. The model considers the main processes occurring in the three phases of a BTF (gas, liquid and biofilm) in a co-current flow mode configuration. Furthermore, this model attempts to describe accurately the intermediate (thiosulfate and elemental sulfur) and final products (sulfate) of H2S oxidation. A sensitivity analysis was performed in order to focus parameters estimation efforts on those parameters that showed the highest influence on the estimation of the H2S removal efficiency, the accumulated mass of sulfur and the sulfate concentration in the liquid phase. Biofilm and liquid layer thicknesses, specific growth rate of biomass over elemental sulfur and the H2S global mass transfer coefficient were the parameters that showed the highest influence on model outputs. Experimental data for model calibration corresponded to the operation of the BTF under stepwise increasing H2S concentrations between 2000 and 10,000 ppmv. Once the model was calibrated, validation was performed by simulating a stationary feeding period of 42 days of operation of the BTF at an average concentration of 2000 ppmv and a dynamic operation period where the BTF was operated under variable inlet H2S concentration between 1000 and 5000 ppmv to simulate load fluctuations occurring in industrial facilities. The model described the reactor performance in terms of H2S removal and predicted satisfactorily the main intermediate and final products produced during the biological oxidation process.

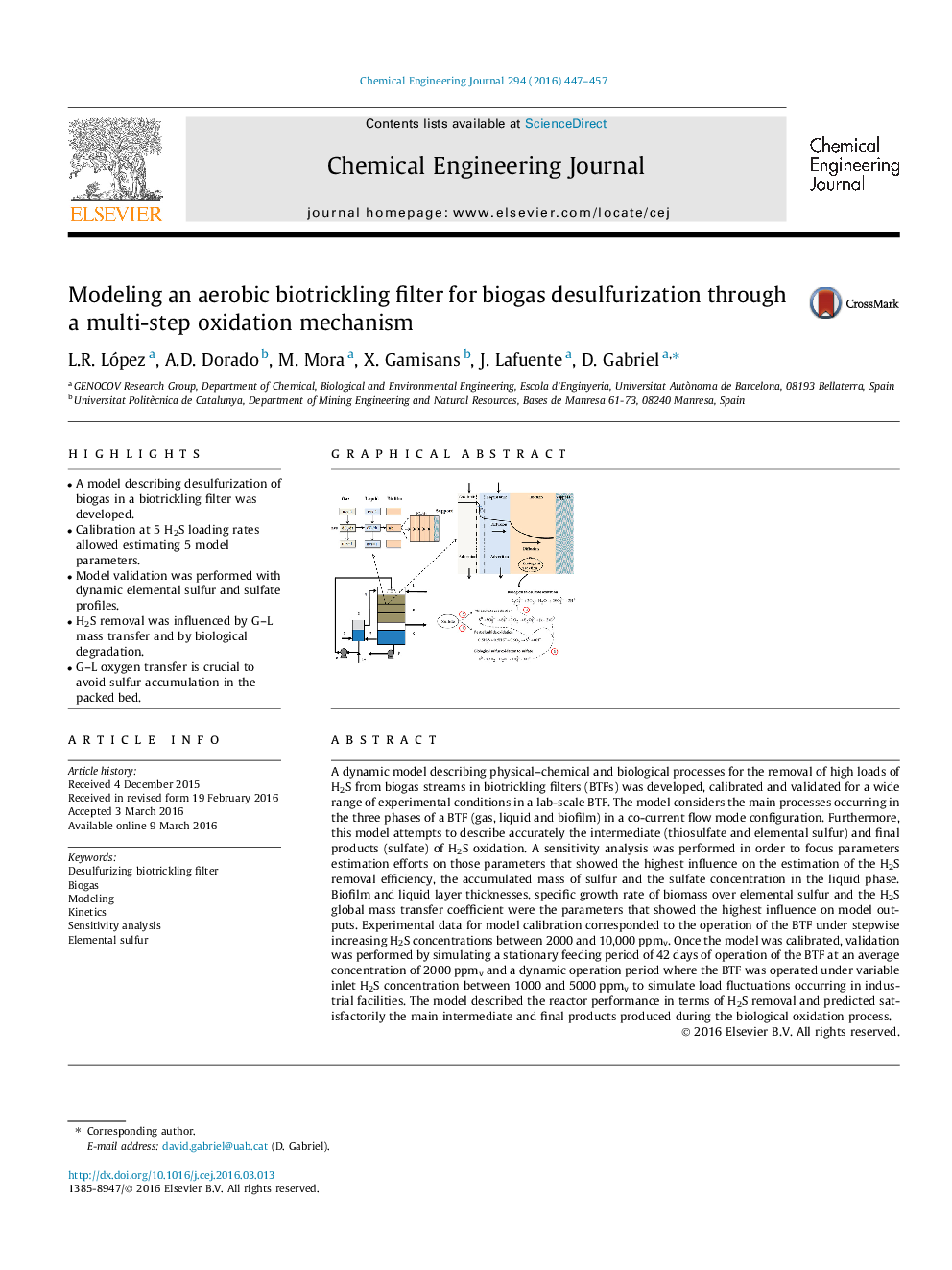

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide