| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 146064 | Chemical Engineering Journal | 2015 | 7 Pages |

•Ferrous hydroxy complex was employed as an excellent reductant for nitrite.•The production of nitrous oxide and ammonium highly depends on the dosage of Fe2+, oxygen, OH− and trace metals.•Decreasing the yield of ammonium and increasing the removal rate of TN.•The presence of trace metals accelerate the nitrite reduction.

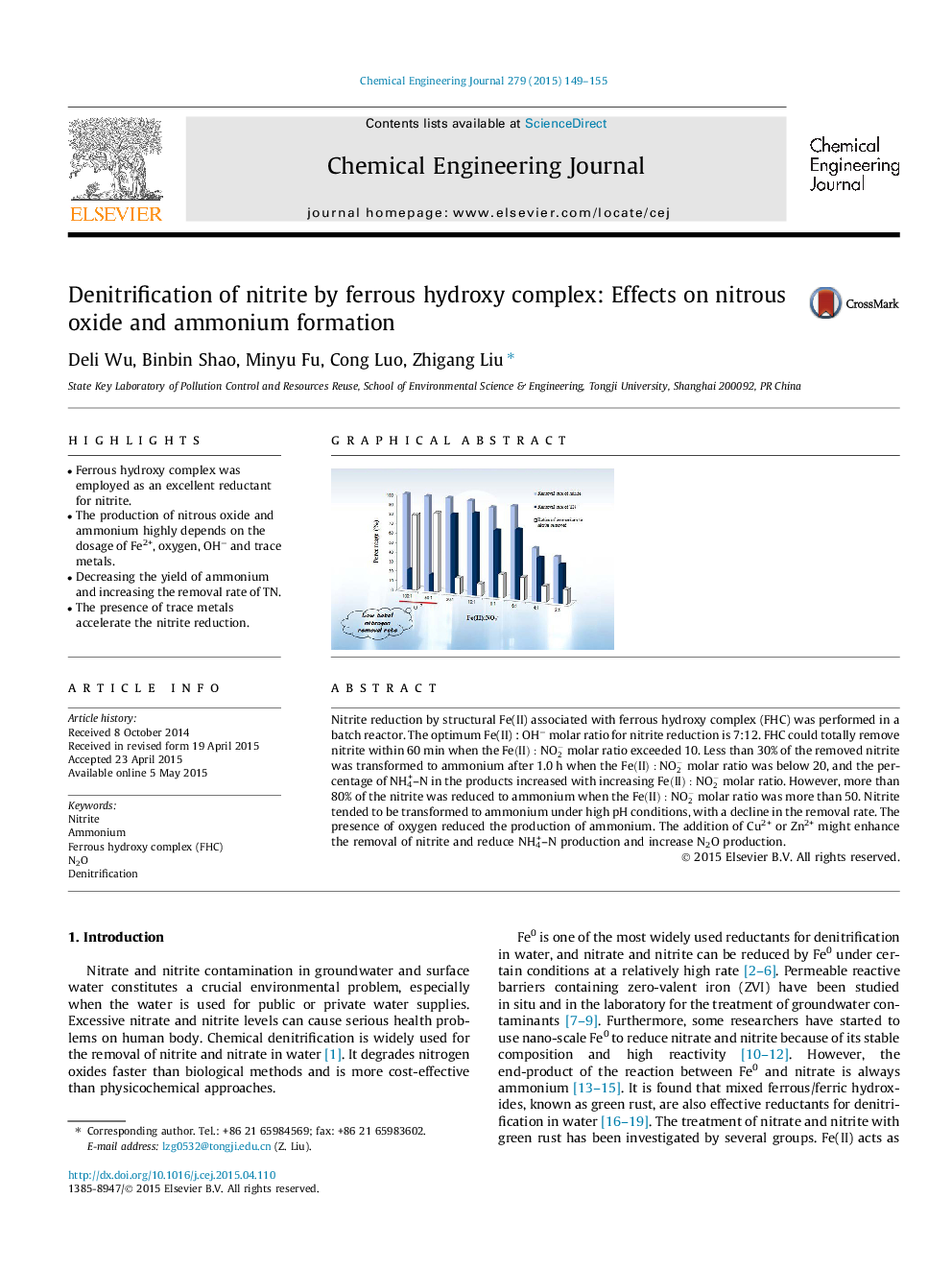

Nitrite reduction by structural Fe(II) associated with ferrous hydroxy complex (FHC) was performed in a batch reactor. The optimum Fe(II):OH− molar ratio for nitrite reduction is 7:12. FHC could totally remove nitrite within 60 min when the Fe(II):NO2- molar ratio exceeded 10. Less than 30% of the removed nitrite was transformed to ammonium after 1.0 h when the Fe(II):NO2- molar ratio was below 20, and the percentage of NH4+–N in the products increased with increasing Fe(II):NO2- molar ratio. However, more than 80% of the nitrite was reduced to ammonium when the Fe(II):NO2- molar ratio was more than 50. Nitrite tended to be transformed to ammonium under high pH conditions, with a decline in the removal rate. The presence of oxygen reduced the production of ammonium. The addition of Cu2+ or Zn2+ might enhance the removal of nitrite and reduce NH4+–N production and increase N2O production.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide