| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 146134 | Chemical Engineering Journal | 2015 | 19 Pages |

•The DEM with signed distance function was validated in a twin-screw kneader.•Mixing mechanism behind observed phenomena was clarified by numerical simulation.•Avalanches occurred near the boundary of two rooms enhanced the mixing efficiency.•Amount of powder greatly influenced mixing efficiency in the twin-screw kneader.

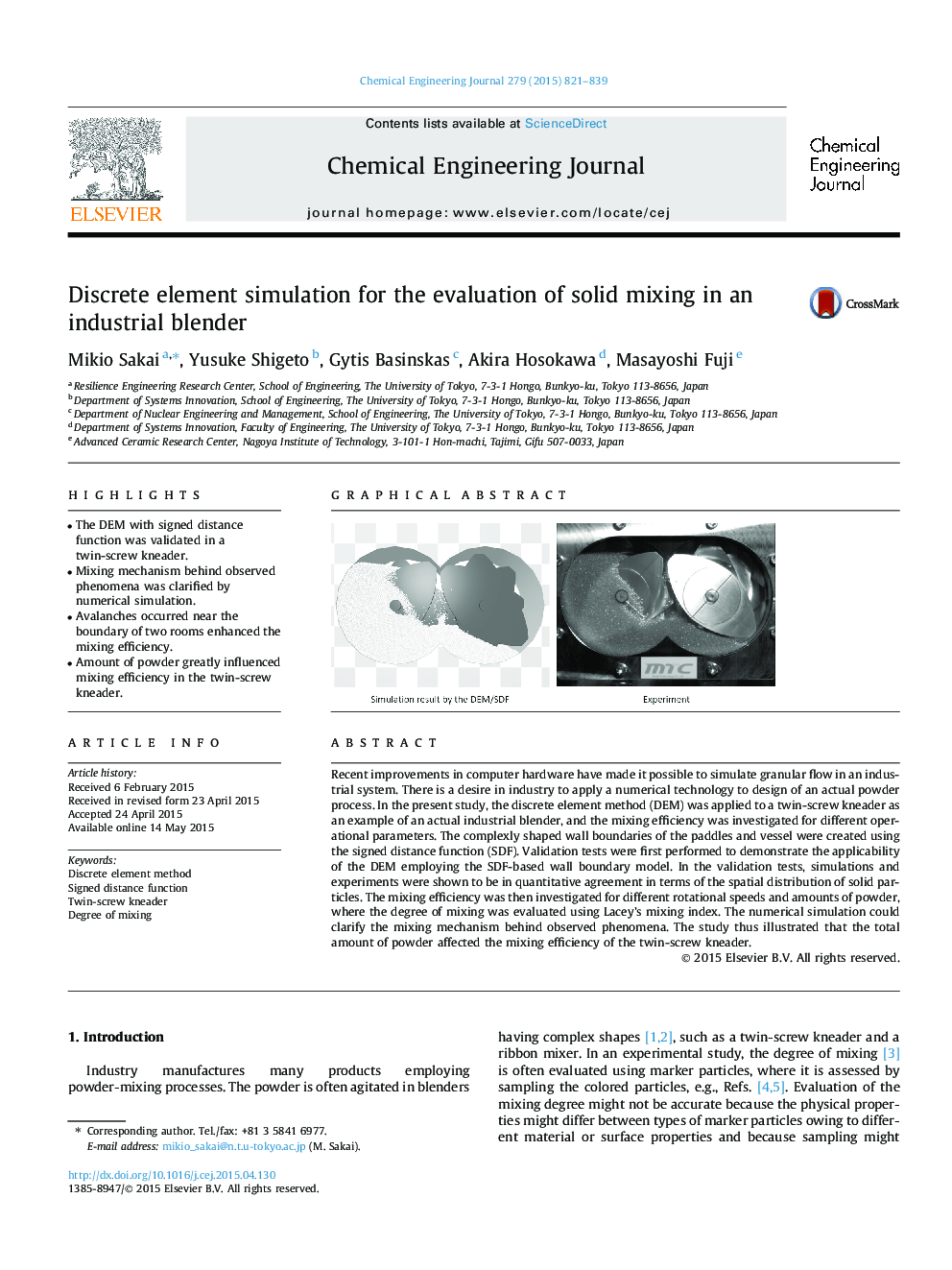

Recent improvements in computer hardware have made it possible to simulate granular flow in an industrial system. There is a desire in industry to apply a numerical technology to design of an actual powder process. In the present study, the discrete element method (DEM) was applied to a twin-screw kneader as an example of an actual industrial blender, and the mixing efficiency was investigated for different operational parameters. The complexly shaped wall boundaries of the paddles and vessel were created using the signed distance function (SDF). Validation tests were first performed to demonstrate the applicability of the DEM employing the SDF-based wall boundary model. In the validation tests, simulations and experiments were shown to be in quantitative agreement in terms of the spatial distribution of solid particles. The mixing efficiency was then investigated for different rotational speeds and amounts of powder, where the degree of mixing was evaluated using Lacey’s mixing index. The numerical simulation could clarify the mixing mechanism behind observed phenomena. The study thus illustrated that the total amount of powder affected the mixing efficiency of the twin-screw kneader.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide