| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 146582 | Chemical Engineering Journal | 2015 | 9 Pages |

•Ionic liquid–heptane dispersion was studied as model system for ionic liquid alkylation process.•FBRM and PVM were successfully used to determine the phase inversion and droplet size distribution respectively.•The phase inversion point was close to the heptane holdup of 0.5.•Self-similar droplet size distribution of IL-continuous dispersion was found.•A semi-empirical correlation is proposed to predict the Sauter diameter of the heptane droplets.

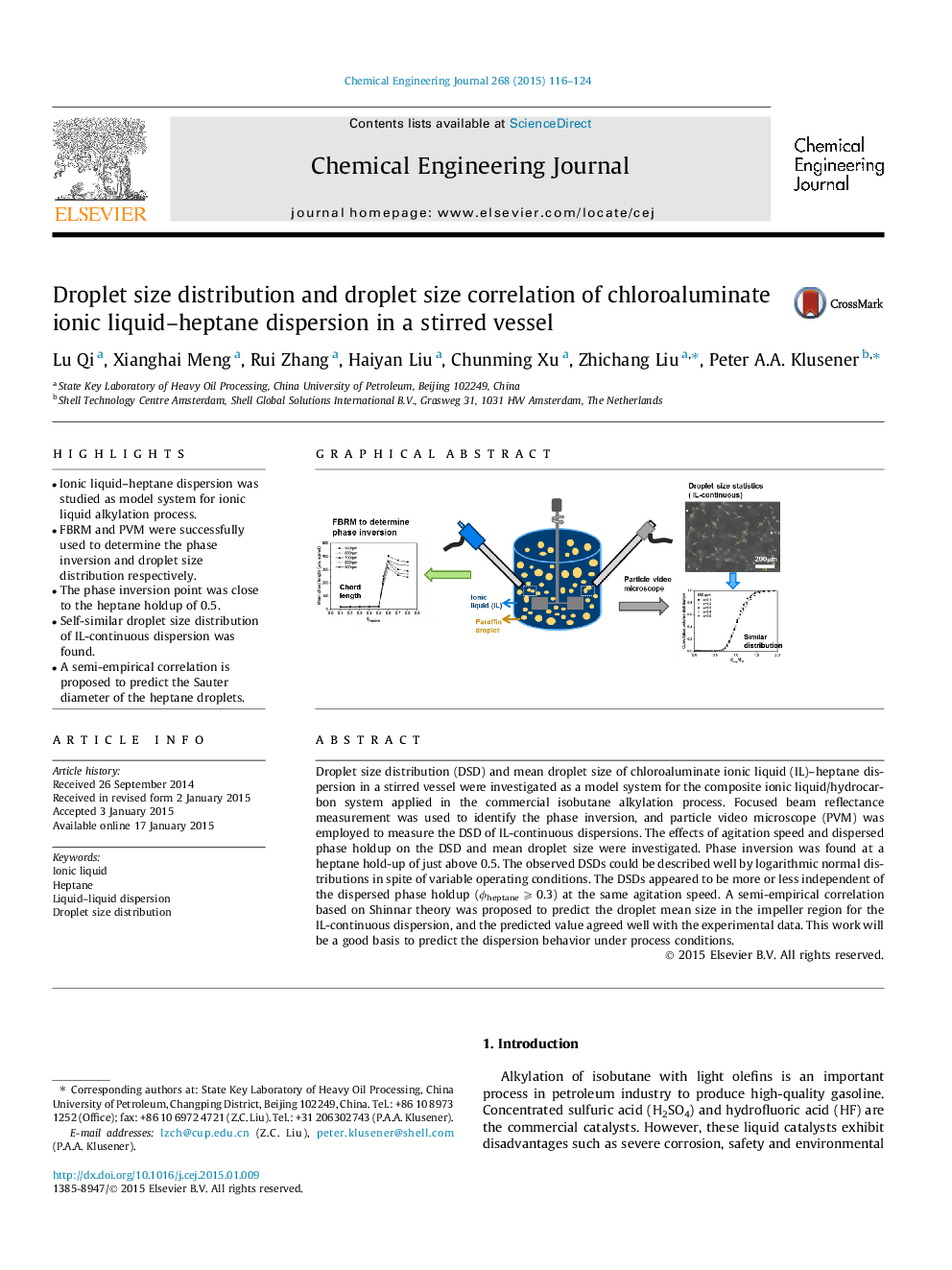

Droplet size distribution (DSD) and mean droplet size of chloroaluminate ionic liquid (IL)–heptane dispersion in a stirred vessel were investigated as a model system for the composite ionic liquid/hydrocarbon system applied in the commercial isobutane alkylation process. Focused beam reflectance measurement was used to identify the phase inversion, and particle video microscope (PVM) was employed to measure the DSD of IL-continuous dispersions. The effects of agitation speed and dispersed phase holdup on the DSD and mean droplet size were investigated. Phase inversion was found at a heptane hold-up of just above 0.5. The observed DSDs could be described well by logarithmic normal distributions in spite of variable operating conditions. The DSDs appeared to be more or less independent of the dispersed phase holdup (ϕheptane ⩾ 0.3) at the same agitation speed. A semi-empirical correlation based on Shinnar theory was proposed to predict the droplet mean size in the impeller region for the IL-continuous dispersion, and the predicted value agreed well with the experimental data. This work will be a good basis to predict the dispersion behavior under process conditions.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide