| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 146738 | Chemical Engineering Journal | 2015 | 11 Pages |

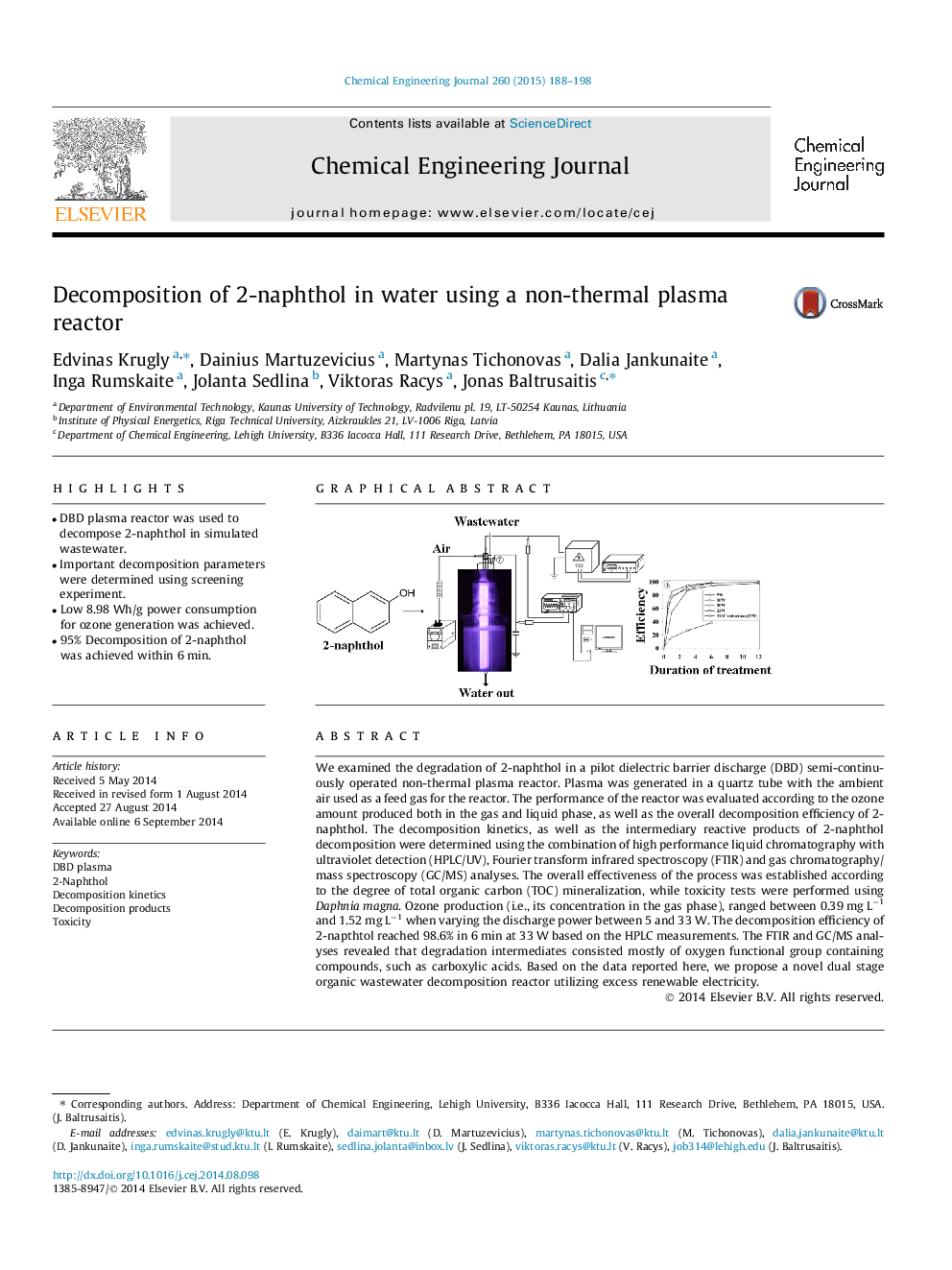

•DBD plasma reactor was used to decompose 2-naphthol in simulated wastewater.•Important decomposition parameters were determined using screening experiment.•Low 8.98 Wh/g power consumption for ozone generation was achieved.•95% Decomposition of 2-naphthol was achieved within 6 min.

We examined the degradation of 2-naphthol in a pilot dielectric barrier discharge (DBD) semi-continuously operated non-thermal plasma reactor. Plasma was generated in a quartz tube with the ambient air used as a feed gas for the reactor. The performance of the reactor was evaluated according to the ozone amount produced both in the gas and liquid phase, as well as the overall decomposition efficiency of 2-naphthol. The decomposition kinetics, as well as the intermediary reactive products of 2-naphthol decomposition were determined using the combination of high performance liquid chromatography with ultraviolet detection (HPLC/UV), Fourier transform infrared spectroscopy (FTIR) and gas chromatography/mass spectroscopy (GC/MS) analyses. The overall effectiveness of the process was established according to the degree of total organic carbon (TOC) mineralization, while toxicity tests were performed using Daphnia magna. Ozone production (i.e., its concentration in the gas phase), ranged between 0.39 mg L−1 and 1.52 mg L−1 when varying the discharge power between 5 and 33 W. The decomposition efficiency of 2-napthtol reached 98.6% in 6 min at 33 W based on the HPLC measurements. The FTIR and GC/MS analyses revealed that degradation intermediates consisted mostly of oxygen functional group containing compounds, such as carboxylic acids. Based on the data reported here, we propose a novel dual stage organic wastewater decomposition reactor utilizing excess renewable electricity.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide