| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 146884 | Chemical Engineering Journal | 2015 | 9 Pages |

•A practical, model-based, ammonia dosing strategy is presented.•The dosing strategy is optimized and applied to SCR demonstration examples.•Performance comparison of different catalyst materials (iron and copper).•Investigating the sensitivity of the performance towards change in storage capacity.•The examples demonstrate the importance of an individually adjusted dosing strategy.

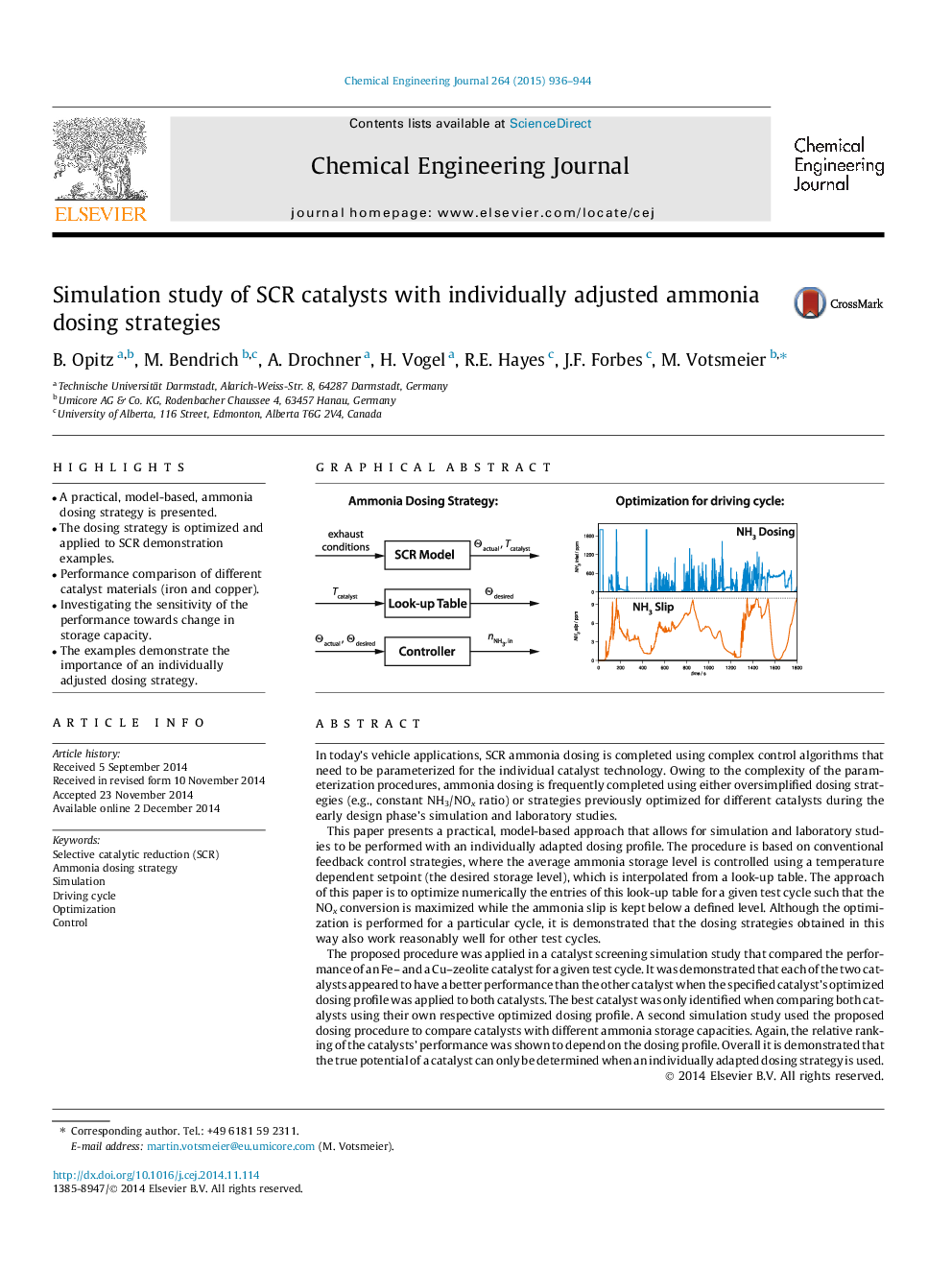

In today’s vehicle applications, SCR ammonia dosing is completed using complex control algorithms that need to be parameterized for the individual catalyst technology. Owing to the complexity of the parameterization procedures, ammonia dosing is frequently completed using either oversimplified dosing strategies (e.g., constant NH3/NOx ratio) or strategies previously optimized for different catalysts during the early design phase’s simulation and laboratory studies.This paper presents a practical, model-based approach that allows for simulation and laboratory studies to be performed with an individually adapted dosing profile. The procedure is based on conventional feedback control strategies, where the average ammonia storage level is controlled using a temperature dependent setpoint (the desired storage level), which is interpolated from a look-up table. The approach of this paper is to optimize numerically the entries of this look-up table for a given test cycle such that the NOx conversion is maximized while the ammonia slip is kept below a defined level. Although the optimization is performed for a particular cycle, it is demonstrated that the dosing strategies obtained in this way also work reasonably well for other test cycles.The proposed procedure was applied in a catalyst screening simulation study that compared the performance of an Fe– and a Cu–zeolite catalyst for a given test cycle. It was demonstrated that each of the two catalysts appeared to have a better performance than the other catalyst when the specified catalyst’s optimized dosing profile was applied to both catalysts. The best catalyst was only identified when comparing both catalysts using their own respective optimized dosing profile. A second simulation study used the proposed dosing procedure to compare catalysts with different ammonia storage capacities. Again, the relative ranking of the catalysts’ performance was shown to depend on the dosing profile. Overall it is demonstrated that the true potential of a catalyst can only be determined when an individually adapted dosing strategy is used.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide