| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 146911 | Chemical Engineering Journal | 2015 | 9 Pages |

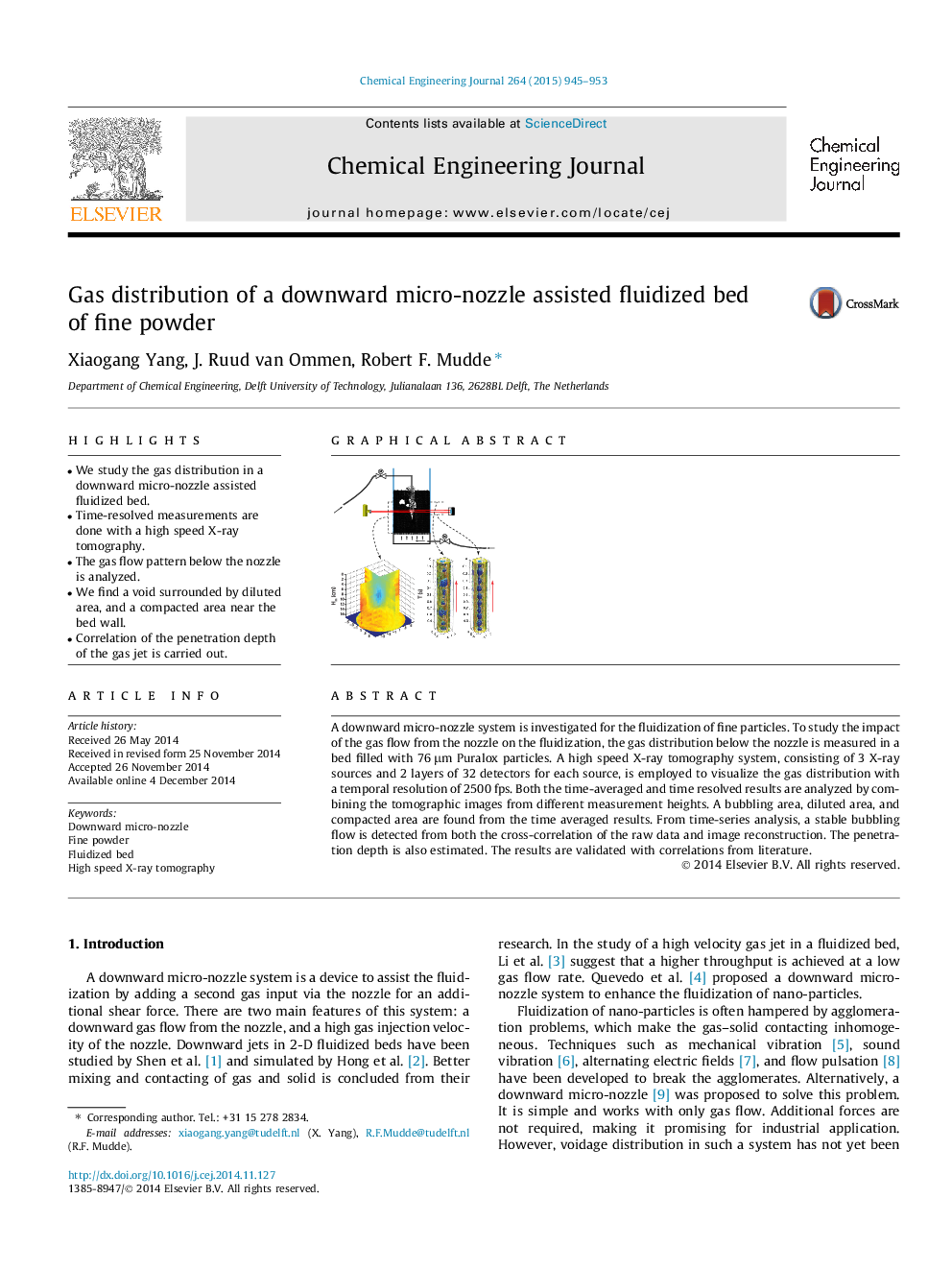

•We study the gas distribution in a downward micro-nozzle assisted fluidized bed.•Time-resolved measurements are done with a high speed X-ray tomography.•The gas flow pattern below the nozzle is analyzed.•We find a void surrounded by diluted area, and a compacted area near the bed wall.•Correlation of the penetration depth of the gas jet is carried out.

A downward micro-nozzle system is investigated for the fluidization of fine particles. To study the impact of the gas flow from the nozzle on the fluidization, the gas distribution below the nozzle is measured in a bed filled with 76 μm Puralox particles. A high speed X-ray tomography system, consisting of 3 X-ray sources and 2 layers of 32 detectors for each source, is employed to visualize the gas distribution with a temporal resolution of 2500 fps. Both the time-averaged and time resolved results are analyzed by combining the tomographic images from different measurement heights. A bubbling area, diluted area, and compacted area are found from the time averaged results. From time-series analysis, a stable bubbling flow is detected from both the cross-correlation of the raw data and image reconstruction. The penetration depth is also estimated. The results are validated with correlations from literature.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide