| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 147190 | Chemical Engineering Journal | 2014 | 10 Pages |

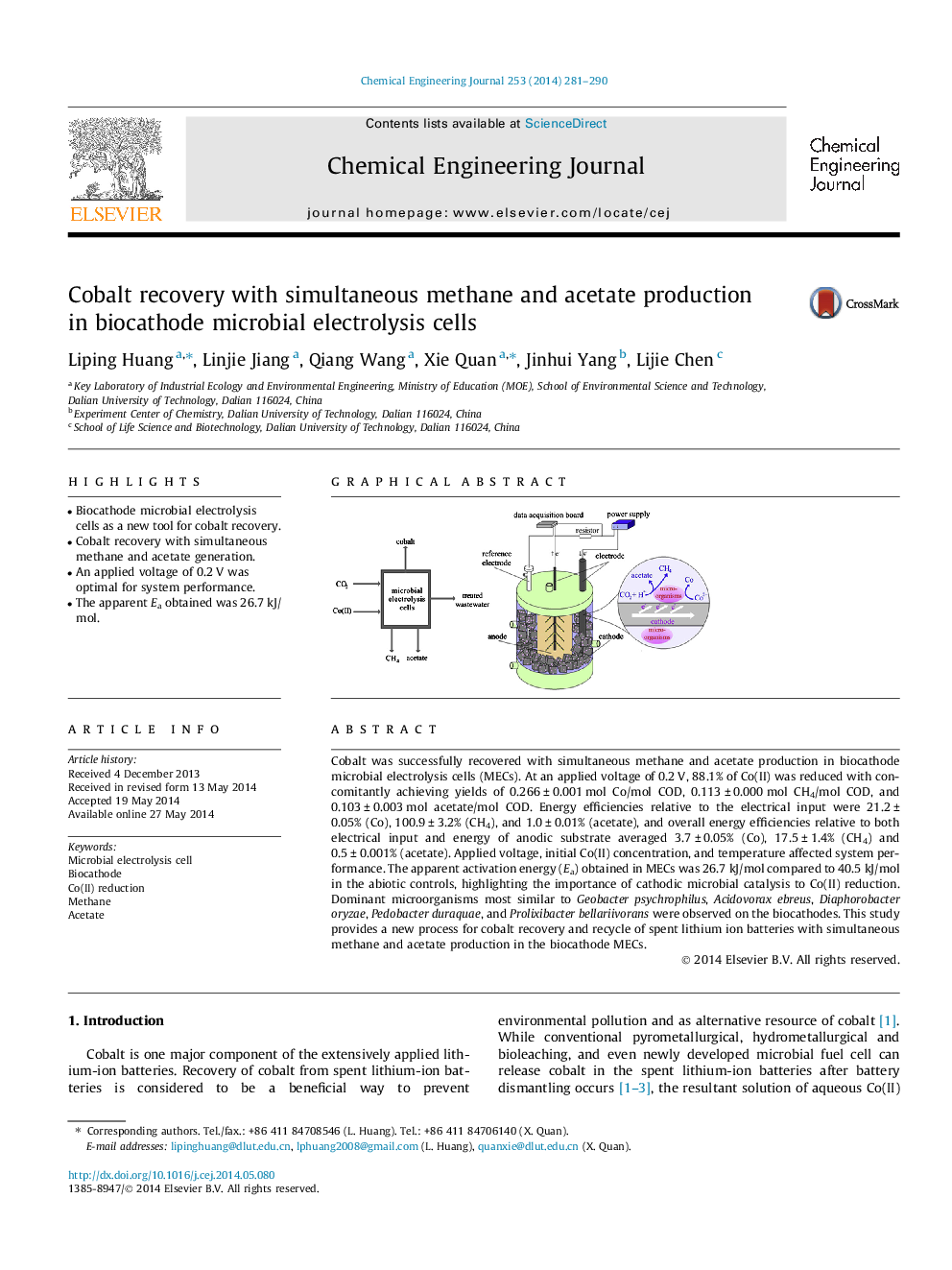

•Biocathode microbial electrolysis cells as a new tool for cobalt recovery.•Cobalt recovery with simultaneous methane and acetate generation.•An applied voltage of 0.2 V was optimal for system performance.•The apparent Ea obtained was 26.7 kJ/mol.

Cobalt was successfully recovered with simultaneous methane and acetate production in biocathode microbial electrolysis cells (MECs). At an applied voltage of 0.2 V, 88.1% of Co(II) was reduced with concomitantly achieving yields of 0.266 ± 0.001 mol Co/mol COD, 0.113 ± 0.000 mol CH4/mol COD, and 0.103 ± 0.003 mol acetate/mol COD. Energy efficiencies relative to the electrical input were 21.2 ± 0.05% (Co), 100.9 ± 3.2% (CH4), and 1.0 ± 0.01% (acetate), and overall energy efficiencies relative to both electrical input and energy of anodic substrate averaged 3.7 ± 0.05% (Co), 17.5 ± 1.4% (CH4) and 0.5 ± 0.001% (acetate). Applied voltage, initial Co(II) concentration, and temperature affected system performance. The apparent activation energy (Ea) obtained in MECs was 26.7 kJ/mol compared to 40.5 kJ/mol in the abiotic controls, highlighting the importance of cathodic microbial catalysis to Co(II) reduction. Dominant microorganisms most similar to Geobacter psychrophilus, Acidovorax ebreus, Diaphorobacter oryzae, Pedobacter duraquae, and Prolixibacter bellariivorans were observed on the biocathodes. This study provides a new process for cobalt recovery and recycle of spent lithium ion batteries with simultaneous methane and acetate production in the biocathode MECs.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide