| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 147300 | Chemical Engineering Journal | 2014 | 7 Pages |

•Centrifugal jet spinning is an efficient and low cost nanofiber fabrication method.•CJS production rate is 500 times higher comparing to electrospinning method.•Dual solvent evaporation induced phase separation created hollow structured fibers.•Large amount of silica nanotubes were obtained with controlled morphologies.•The silica nanotube wall thickness is tunable with current method.

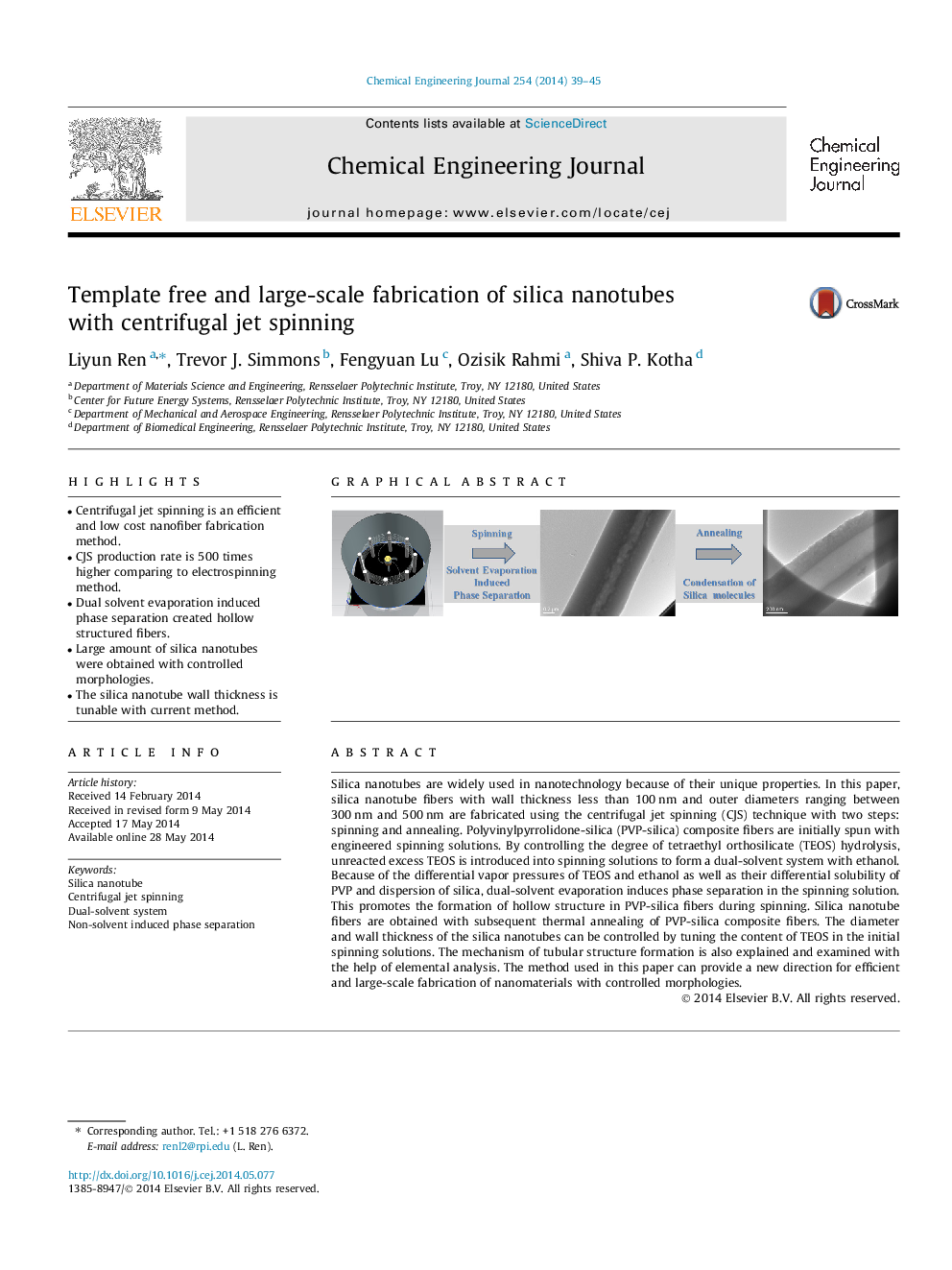

Silica nanotubes are widely used in nanotechnology because of their unique properties. In this paper, silica nanotube fibers with wall thickness less than 100 nm and outer diameters ranging between 300 nm and 500 nm are fabricated using the centrifugal jet spinning (CJS) technique with two steps: spinning and annealing. Polyvinylpyrrolidone-silica (PVP-silica) composite fibers are initially spun with engineered spinning solutions. By controlling the degree of tetraethyl orthosilicate (TEOS) hydrolysis, unreacted excess TEOS is introduced into spinning solutions to form a dual-solvent system with ethanol. Because of the differential vapor pressures of TEOS and ethanol as well as their differential solubility of PVP and dispersion of silica, dual-solvent evaporation induces phase separation in the spinning solution. This promotes the formation of hollow structure in PVP-silica fibers during spinning. Silica nanotube fibers are obtained with subsequent thermal annealing of PVP-silica composite fibers. The diameter and wall thickness of the silica nanotubes can be controlled by tuning the content of TEOS in the initial spinning solutions. The mechanism of tubular structure formation is also explained and examined with the help of elemental analysis. The method used in this paper can provide a new direction for efficient and large-scale fabrication of nanomaterials with controlled morphologies.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide