| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 147389 | Chemical Engineering Journal | 2014 | 10 Pages |

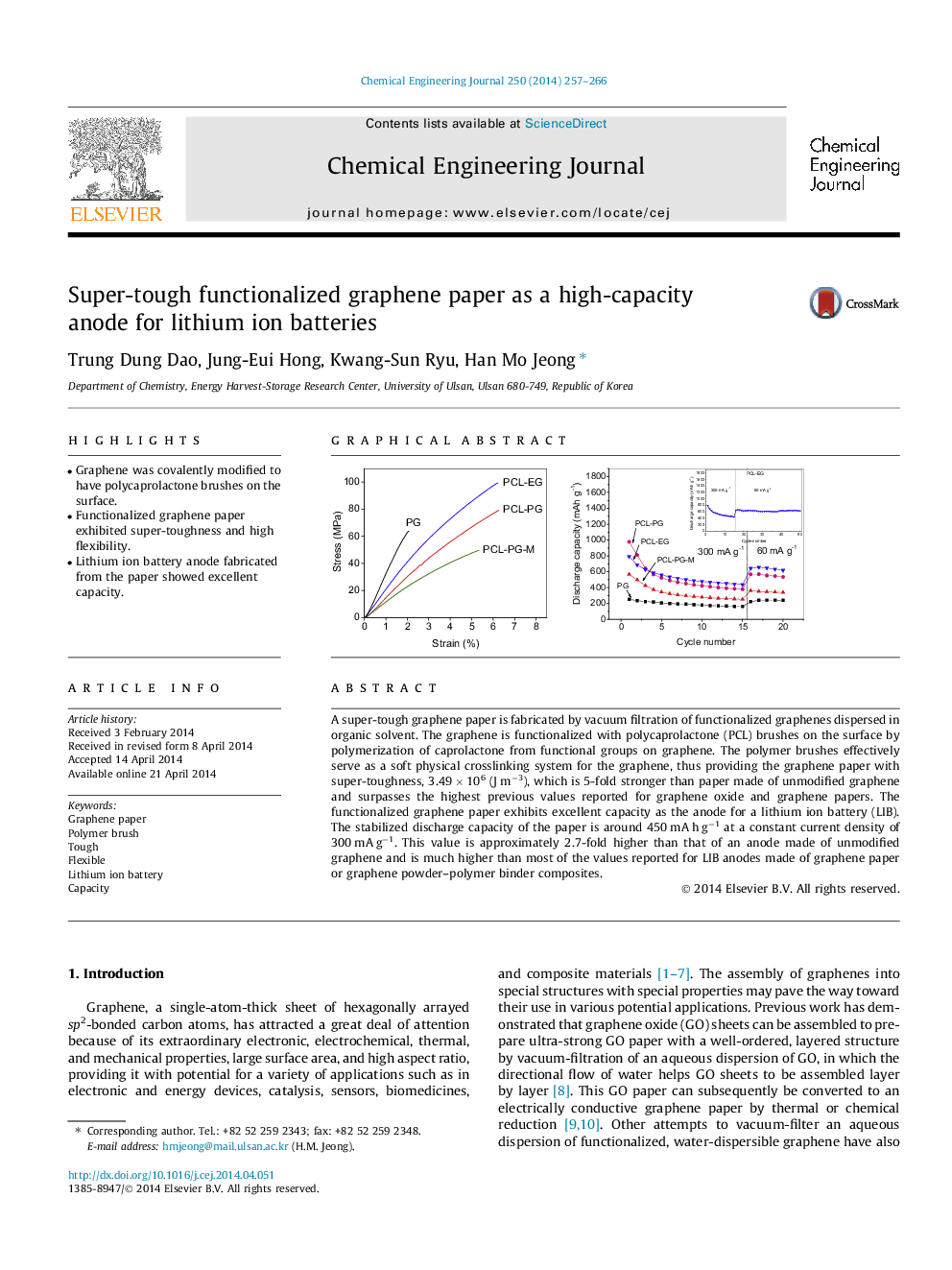

•Graphene was covalently modified to have polycaprolactone brushes on the surface.•Functionalized graphene paper exhibited super-toughness and high flexibility.•Lithium ion battery anode fabricated from the paper showed excellent capacity.

A super-tough graphene paper is fabricated by vacuum filtration of functionalized graphenes dispersed in organic solvent. The graphene is functionalized with polycaprolactone (PCL) brushes on the surface by polymerization of caprolactone from functional groups on graphene. The polymer brushes effectively serve as a soft physical crosslinking system for the graphene, thus providing the graphene paper with super-toughness, 3.49 × 106 (J m−3), which is 5-fold stronger than paper made of unmodified graphene and surpasses the highest previous values reported for graphene oxide and graphene papers. The functionalized graphene paper exhibits excellent capacity as the anode for a lithium ion battery (LIB). The stabilized discharge capacity of the paper is around 450 mA h g−1 at a constant current density of 300 mA g−1. This value is approximately 2.7-fold higher than that of an anode made of unmodified graphene and is much higher than most of the values reported for LIB anodes made of graphene paper or graphene powder–polymer binder composites.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide