| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 147659 | Chemical Engineering Journal | 2014 | 11 Pages |

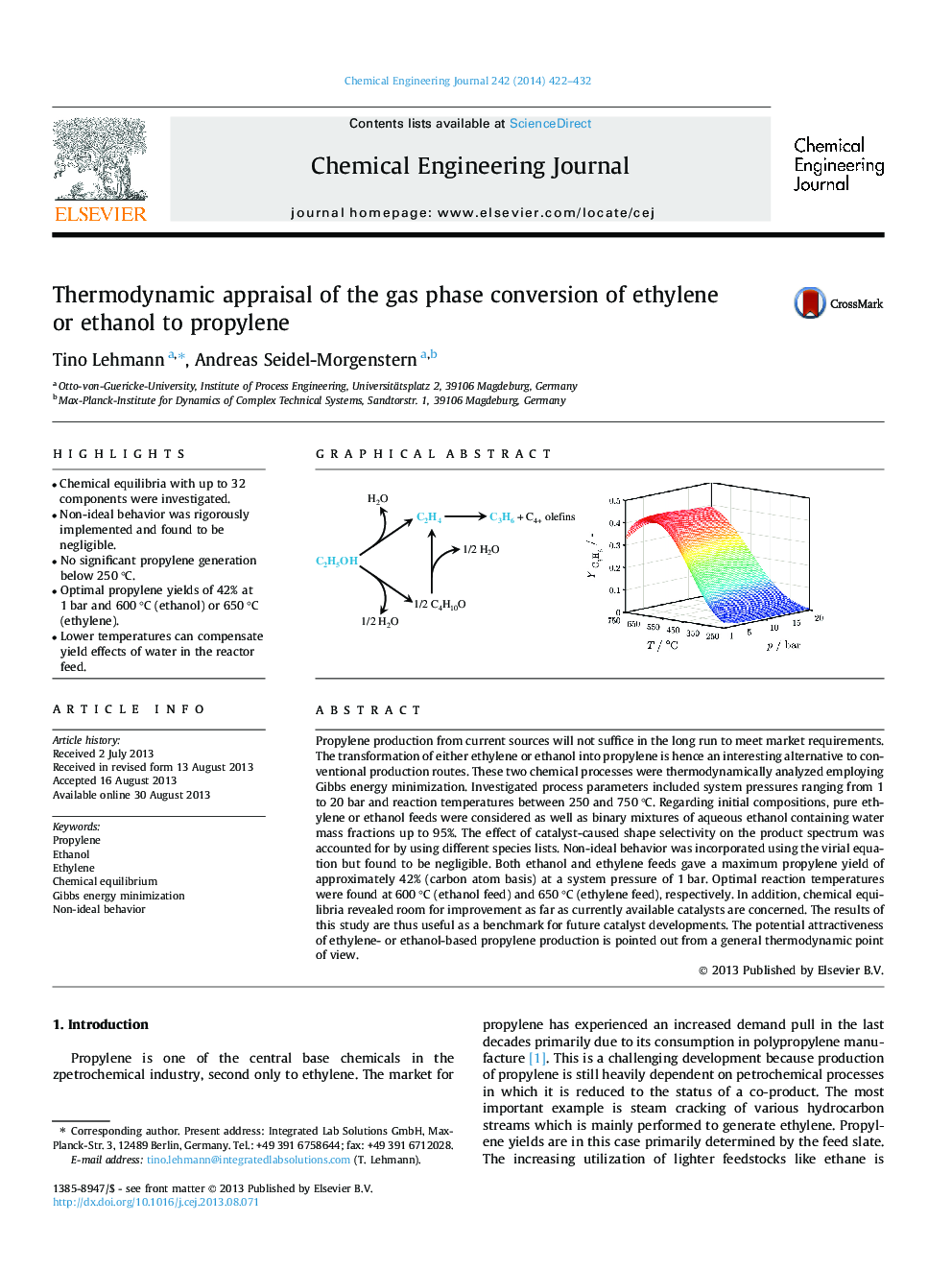

•Chemical equilibria with up to 32 components were investigated.•Non-ideal behavior was rigorously implemented and found to be negligible.•No significant propylene generation below 250 °C.•Optimal propylene yields of 42% at 1 bar and 600 °C (ethanol) or 650 °C (ethylene).•Lower temperatures can compensate yield effects of water in the reactor feed.

Propylene production from current sources will not suffice in the long run to meet market requirements. The transformation of either ethylene or ethanol into propylene is hence an interesting alternative to conventional production routes. These two chemical processes were thermodynamically analyzed employing Gibbs energy minimization. Investigated process parameters included system pressures ranging from 1 to 20 bar and reaction temperatures between 250 and 750 °C. Regarding initial compositions, pure ethylene or ethanol feeds were considered as well as binary mixtures of aqueous ethanol containing water mass fractions up to 95%. The effect of catalyst-caused shape selectivity on the product spectrum was accounted for by using different species lists. Non-ideal behavior was incorporated using the virial equation but found to be negligible. Both ethanol and ethylene feeds gave a maximum propylene yield of approximately 42% (carbon atom basis) at a system pressure of 1 bar. Optimal reaction temperatures were found at 600 °C (ethanol feed) and 650 °C (ethylene feed), respectively. In addition, chemical equilibria revealed room for improvement as far as currently available catalysts are concerned. The results of this study are thus useful as a benchmark for future catalyst developments. The potential attractiveness of ethylene- or ethanol-based propylene production is pointed out from a general thermodynamic point of view.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide