| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 147689 | Chemical Engineering Journal | 2014 | 8 Pages |

•Fly ash from pine gasification was used as precursor of carbon-based materials.•Materials with ABET of 1171 m2 g−1 were obtain by chemical activation with K2CO3.•The solids were tested for the removal of acetaminophen from aqueous solution.•Molecular dimensions of monomer and dimer were considered in the discussion.•The affinity of paracetamol for the carbon is maximized by pores with width of 0.7 nm.

Fly ash, a residue produced from pine gasification, was used as precursor of carbon-based materials assayed in acetaminophen adsorption. Materials prepared by activation with K2CO3, presented high porosity development (ABET ≈ 1200 m2 g−1) and samples calcined at 900 °C presented high volumes of large micropores and mesopores. Kinetic and equilibrium acetaminophen adsorption data showed that the process obeys to the pseudo-second order kinetic equation and Langmuir model, respectively. The rate of acetaminophen adsorption depends of the presence of larger micropores. For the lab-made samples monolayer adsorption capacities attained values similar to those of commercial carbons. The influence of the micropore size distribution of the carbons in the acetaminophen adsorption process justified the lower adsorption affinities of the lab-made carbons. The importance of pores of a specific dimension (0.7 nm) to enhance the affinity of the molecule towards the carbon surface was demonstrated. The increase of temperature lead to higher monolayer adsorption capacities, most likely due to the easier accessibility of the acetaminophen species to the narrowest micropores.

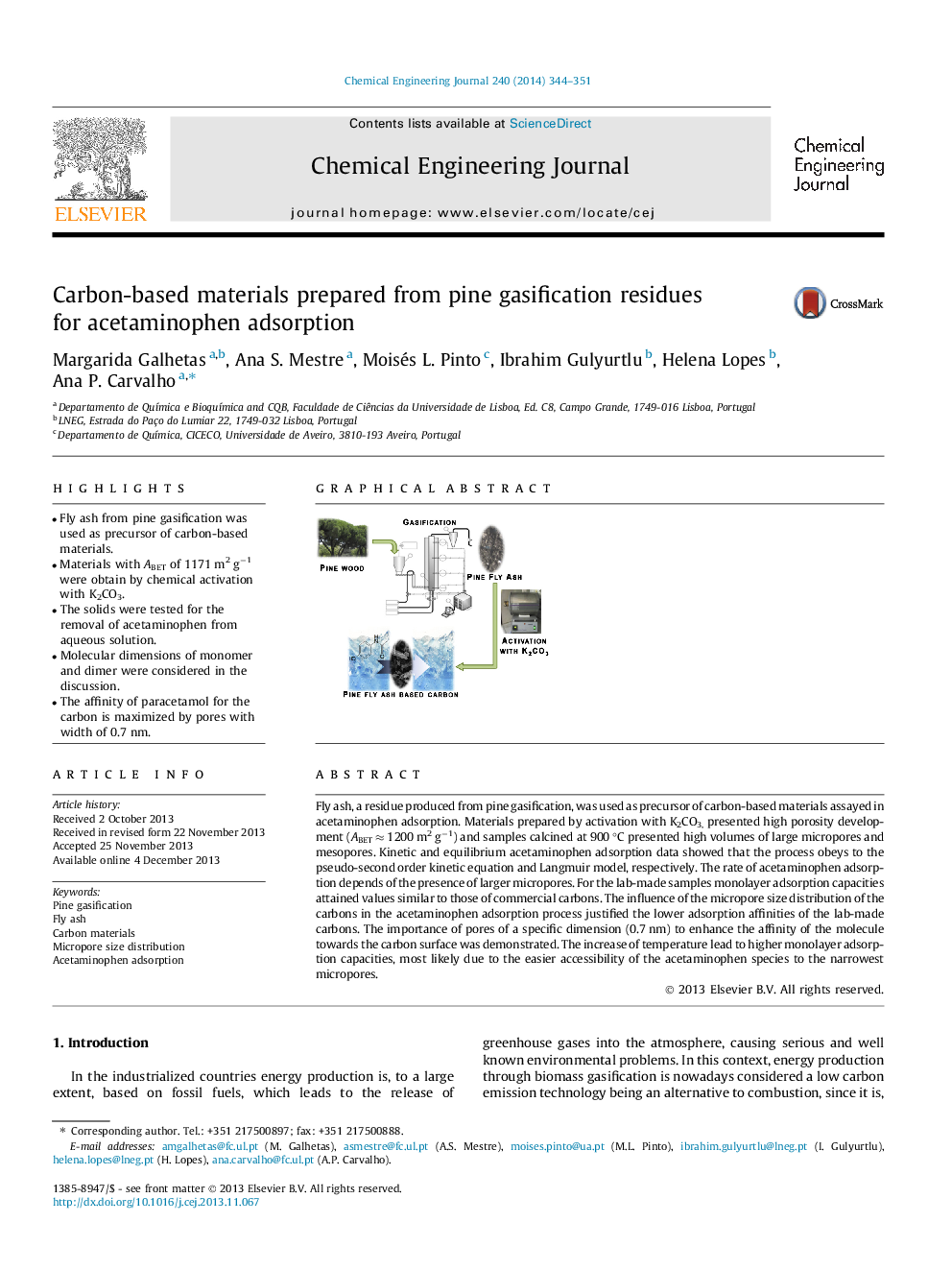

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide