| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 147735 | Chemical Engineering Journal | 2014 | 11 Pages |

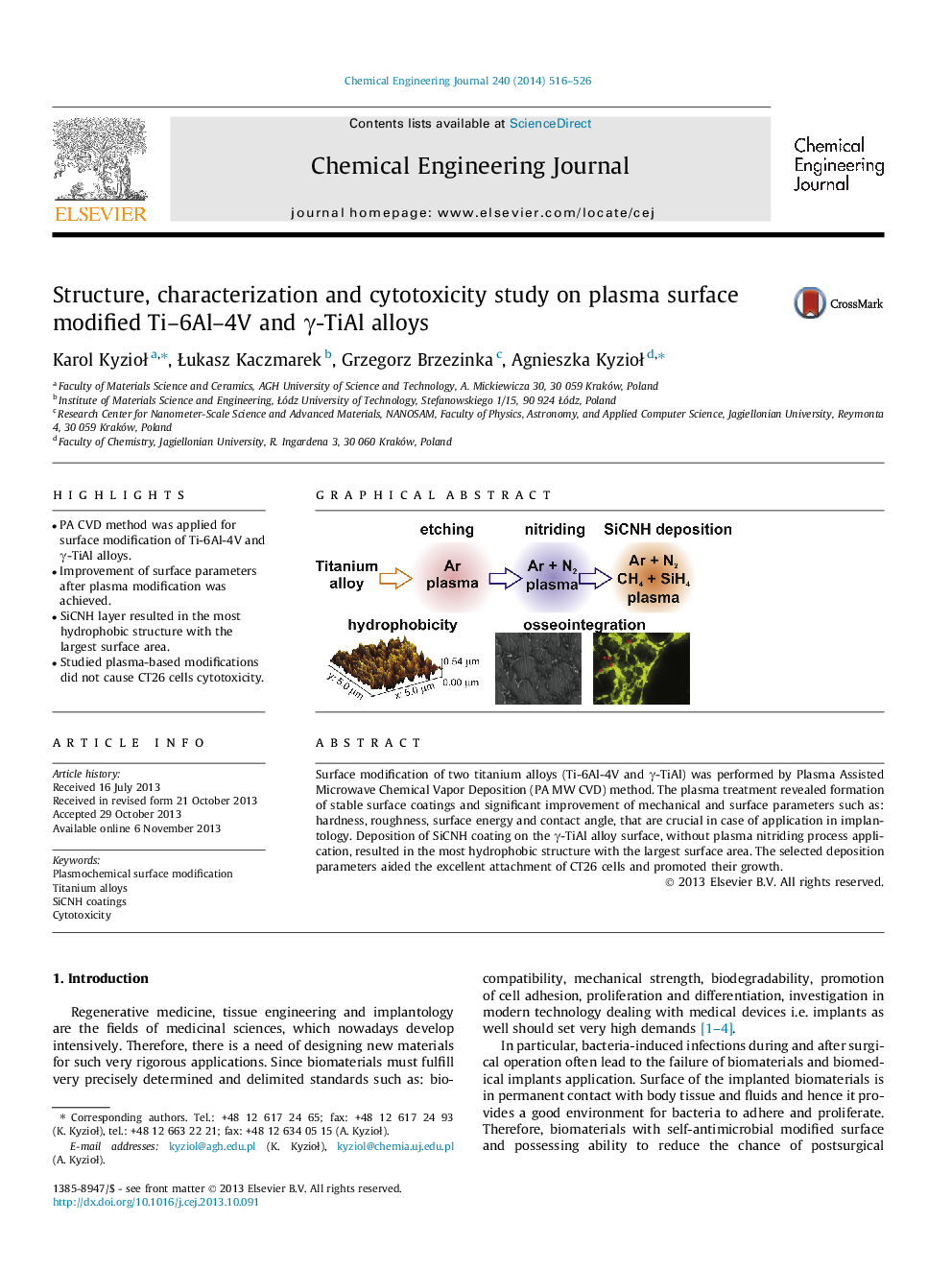

•PA CVD method was applied for surface modification of Ti-6Al-4V and γ-TiAl alloys.•Improvement of surface parameters after plasma modification was achieved.•SiCNH layer resulted in the most hydrophobic structure with the largest surface area.•Studied plasma-based modifications did not cause CT26 cells cytotoxicity.

Surface modification of two titanium alloys (Ti-6Al-4V and γ-TiAl) was performed by Plasma Assisted Microwave Chemical Vapor Deposition (PA MW CVD) method. The plasma treatment revealed formation of stable surface coatings and significant improvement of mechanical and surface parameters such as: hardness, roughness, surface energy and contact angle, that are crucial in case of application in implantology. Deposition of SiCNH coating on the γ-TiAl alloy surface, without plasma nitriding process application, resulted in the most hydrophobic structure with the largest surface area. The selected deposition parameters aided the excellent attachment of CT26 cells and promoted their growth.

Graphical abstractFigure optionsDownload full-size imageDownload as PowerPoint slide