| Article ID | Journal | Published Year | Pages | File Type |

|---|---|---|---|---|

| 147809 | Chemical Engineering Journal | 2014 | 12 Pages |

•Novel electrospinning technique which combines electrospinning and forcespinning was proposed.•A viscoelastic jet has a strong stretching and a fast extension speed force under electrostatic and centrifugal forces.•This technique can remove “whipping instability” and fabricate a series of uniaxially aligned polymeric nanofibers.•Dimensionless groups determine the jet behavior and physical properties of polymeric nanofibers.

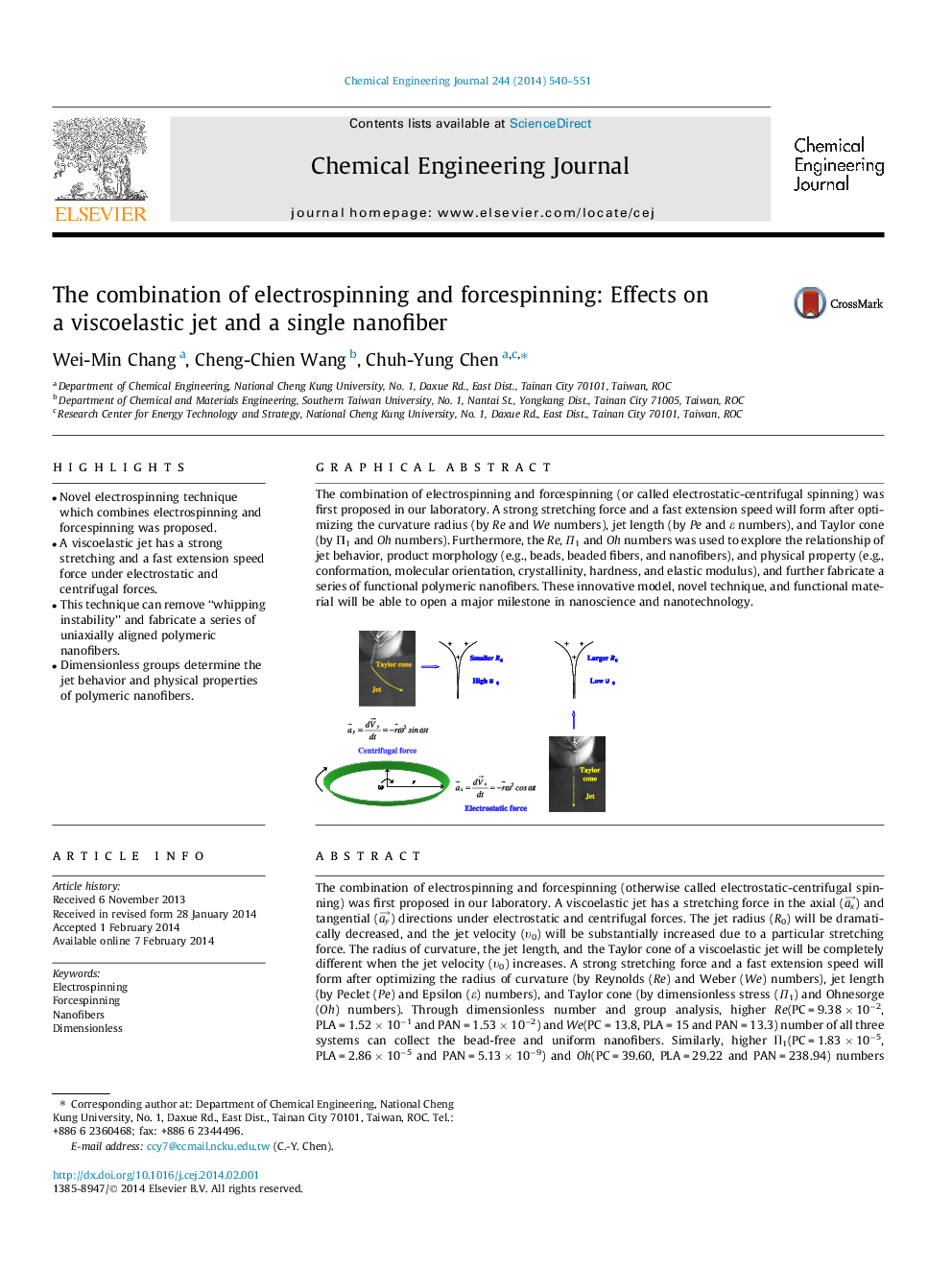

The combination of electrospinning and forcespinning (otherwise called electrostatic-centrifugal spinning) was first proposed in our laboratory. A viscoelastic jet has a stretching force in the axial (ax→) and tangential (ay→) directions under electrostatic and centrifugal forces. The jet radius (R0) will be dramatically decreased, and the jet velocity (υ0) will be substantially increased due to a particular stretching force. The radius of curvature, the jet length, and the Taylor cone of a viscoelastic jet will be completely different when the jet velocity (υ0) increases. A strong stretching force and a fast extension speed will form after optimizing the radius of curvature (by Reynolds (Re) and Weber (We) numbers), jet length (by Peclet (Pe) and Epsilon (ε) numbers), and Taylor cone (by dimensionless stress (Π1) and Ohnesorge (Oh) numbers). Through dimensionless number and group analysis, higher Re(PC = 9.38 × 10−2, PLA = 1.52 × 10−1 and PAN = 1.53 × 10−2) and We(PC = 13.8, PLA = 15 and PAN = 13.3) number of all three systems can collect the bead-free and uniform nanofibers. Similarly, higher П1(PC = 1.83 × 10−5, PLA = 2.86 × 10−5 and PAN = 5.13 × 10−9) and Oh(PC = 39.60, PLA = 29.22 and PAN = 238.94) numbers refer to viscosity and electrostatic force dominate the jet behavior and obtained the nanofiber with high modulus, hardness, crystallinity and good molecular orientation. Hence, the uniaxially aligned polycarbonate, polylactic acid and polyacrylonitrile nanofibers with superior physical properties (modulus ⩾ 2.77 GPa, 3.3 GPa and 1.46 GPa, hardness ⩾ 0.32, 0.26 and 0.22 and crystallinity ⩾ 3%, 37% and 21%) can be successfully manufactured in this process.

Graphical abstractThe combination of electrospinning and forcespinning (or called electrostatic-centrifugal spinning) was first proposed in our laboratory. A strong stretching force and a fast extension speed will form after optimizing the curvature radius (by Re and We numbers), jet length (by Pe and ε numbers), and Taylor cone (by Π1 and Oh numbers). Furthermore, the Re, Π1 and Oh numbers was used to explore the relationship of jet behavior, product morphology (e.g., beads, beaded fibers, and nanofibers), and physical property (e.g., conformation, molecular orientation, crystallinity, hardness, and elastic modulus), and further fabricate a series of functional polymeric nanofibers. These innovative model, novel technique, and functional material will be able to open a major milestone in nanoscience and nanotechnology.Figure optionsDownload full-size imageDownload as PowerPoint slide